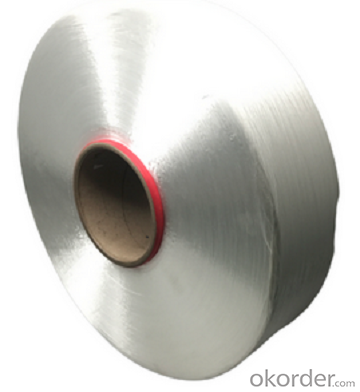

high tenacity twisted industrial polyester FDY yarn

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of FDY Yarn

Material | 100% polyester |

Type | FDY (Fully Drawn Yarn), semidull |

Structure | Multifilament Yarn, Continuous Filament |

Color | White and Black |

Feature | Eco-Friendly, High Strength, |

Application | Knitting, Weaving, Sewing, Embroidery |

Specification | 11-167dtex, 12-144F |

Structure:

1). sheath-core structure: low melting polyester+polyester, Low melting polyester content:30%~40%

2). 100 pure low melting polyester

Feature:

Low melting polyester will be melted at 110/180 degree Celsius and be endowed with adhesive property.

Use low melting polyester is harmless, and enhances the strength of the fabric.

The fabric made with low melting polyester yarn is with high strength, washable, stiff and smooth, easy care.

Low melting polyester yarn owns good adhesiveness and stability, adhesive quickly.

The processing is simple, low energy consumption, nonhazardous, no pollution, Eco-friendly.

Application and suggestion:

1. The adhesive of two layers of sports shoe Upper material —FDY 50D/75D

2. Soft curtain, Zebra curtain, Roman curtain—FDY 75D/150D

3. Vertical blinds—FDY 250D

4. Filter net for air condition—FDY 30D/50D/75D/150D

5. Electromagnetic wire: PET-Glass fiber blended fiber—FDY 50D/75D

6. Garment lining cloth for suit, tie, hat, etc. —FDY 150D/50D/420D

7. Warp knitting fabric such as: Stiff mesh fabric, medical/food filter net, inner car decoration.

8. Top-grade eco-friendly filter material

9. Other applications: protective gloves, dust gauze, top-grade window screen, invisible screen, etc.

- Q: What does JC40S cotton yarn mean?

- Cotton yarn production methods are more complex, in general, there are two kinds of spinning methods, that is, comb cotton spinning and combing spinning. (1) carding cotton spinning process: with cotton → open cotton → carding (2) combing spinning process: with cotton → open cotton → carding → combing → parallel → roving → spun yarn → post-processing → finished product inspection.

- Q: Why in general the yarn in the woven fabric strength coefficient of use greater than 1

- Cotton yarn is made of cotton fiber by spinning the yarn, processed by the stock after the cotton line. According to the different spinning process, can be divided into carded yarn and combed yarn. (1) carded yarn: cotton fiber is the ordinary spinning system spinning yarn

- Q: What is the difference between textile sizing and paper making?

- The modified starch used in papermaking is mainly: acid modified starch (surface sizing), oxidized starch (surface sizing, coating), phosphate starch (surface sizing, coating), oxidized acetate starch (coating) Cationic starch, amphoteric starch (pulp added), grafted starch (coated. Market less) a technology is not up to standard, and then a cost can not accept

- Q: What is Artex and Artex Products?

- Analysis of the industry that, with the improvement of living standards and aesthetic concepts, foreign Artex product market will be further expanded, the development potential is huge.

- Q: Textile spinning yarn should be done first what to do

- Merchandiser refers to the company in the course of operation, customer orders as the basis, tracking products, tracking the flow of services to the full-time staff. (Not part-time, alternative) all around the order to work, the delivery of the person responsible for the delivery, are Merchandiser.

- Q: Will the following kind of yarn which fine? A32 support, B21 support

- 32 branch is relatively small. "Count" is used to indicate the degree of textile fiber thickness of the unit, the higher the number that the fiber, the count is divided into the number of imperial and metric number

- Q: What is the number of yarns used in cotton textiles to mean what is meant

- When the fibers are spun into yarn, they can be woven into a fabric. Because the weaving machine used in the principle of the machine is different, weaving the fabric of the internal structure is different. Usually can be divided into two categories of woven and knitted.

- Q: What is the diameter of a yarn of 40 yarns?

- (Inch): 1 ÷ {0.90 × [(Ne × 840) square)} = 1 ÷ {0.90 × [(40 × 840) square) = 0.006061608 inches

- Q: Men's sweaters with what yarn?

- The end of the proposed: the use of expanded cotton nitrile or other cotton blended yarn, yarn yarn price: 45-55 yuan / Kg or so, high-end: the proposed use of linen cotton or wool composition of the yarn, made of clothing look high fashion, The price will be relatively high.

- Q: From the yarn to the finished textile fabric production process

- Is the famous American chemist Carothers and his research team invented. The main varieties of nylon are nylon 6 and nylon 66, accounting for the absolute dominant, followed by nylon 11, nylon 12, nylon 610, nylon 612, in addition to nylon 1010, nylon 46, nylon 7, nylon 9, nylon 13, Varieties are nylon 6I, nylon 9T and special nylon MXD6 (barrier resin) and so on

Send your message to us

high tenacity twisted industrial polyester FDY yarn

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches