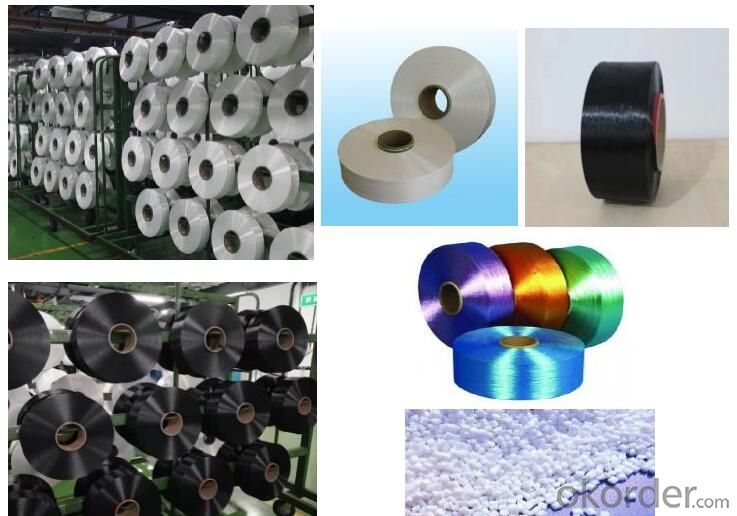

Recycled polyester yarn FDY Brightraw white color polyester monofilament yarn

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of FDY Yarn

Material | 100% polyester |

Type | FDY (Fully Drawn Yarn), semidull |

Structure | Multifilament Yarn, Continuous Filament |

Color | White and Black |

Feature | Eco-Friendly, High Strength, |

Application | Knitting, Weaving, Sewing, Embroidery |

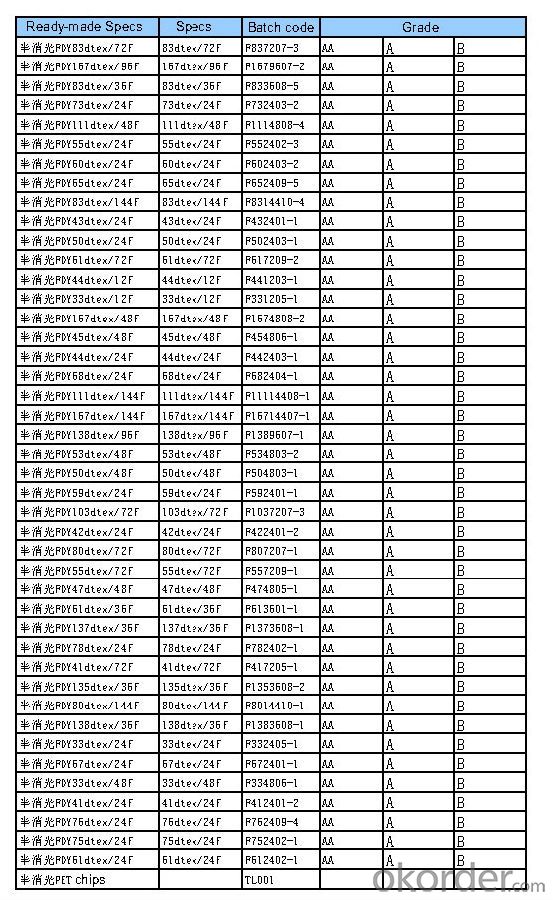

Specification | 11-167dtex, 12-144F |

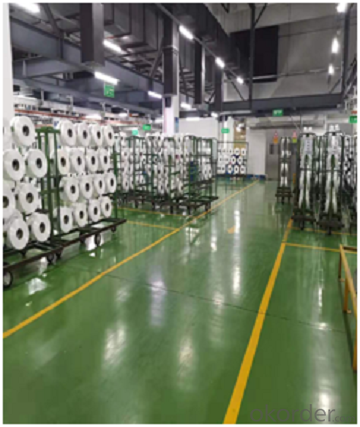

Production Capacity of FDY Yarn

The production capacity is 200,000 TONS per year for now and it will be of 500,000 per year after the erection of the second production line.

Package of FDY Yarn

The FDY yarned is packed by plastic film, paper board, foam board and wooden pallets. Each pallets is about 640-720kg. Box package is also available.

Feature:

Low melting polyester will be melted at 110/180 degree Celsius and be endowed with adhesive property.

Use low melting polyester is harmless, and enhances the strength of the fabric.

The fabric made with low melting polyester yarn is with high strength, washable, stiff and smooth, easy care.

Low melting polyester yarn owns good adhesiveness and stability, adhesive quickly.

The processing is simple, low energy consumption, nonhazardous, no pollution, Eco-friendly.

Regular Specifications

- Q: Why in general the yarn in the woven fabric strength coefficient of use greater than 1

- Introduction 1. Processing of cotton yarn manufacturing methods are more complex, in general, there are two kinds of spinning methods, that is, carded spinning and combing spinning. (1) carded spinning process: with cotton → open cotton → carding → parallel → roving → spun yarn → post-processing → finished product inspection. (2) combing spinning process: with cotton → open cotton → carding → strip → strip → combing → parallel → roving → spun yarn → post-processing → finished product inspection.

- Q: What is the cheese yarn?

- Usually called "cheese yarn"; size - such as diameter about ∮ 250mm or so, the height of about 150mm or so different specifications, requiring no joints (air splicing) or small and fast joints, and forming a good internal and external tension evenly.

- Q: How does textile twist yarn identify?

- Different textile fibers, chemical composition is different, in the combustion process of course have different phenomena

- Q: What is the textile bobbin?

- It overcomes the outer yarn of the cheese yarn is easy to be humidified, and the inner layer of the inner wall of the tube is still dry, resulting in the inner layer yarn and the outer layer of the humidity is not consistent, not easy to knit or wool shortcomings, so that the cheese yarn humidification evenly.

- Q: What is the meaning of the yarn?

- After a certain number of turns around, the jumper yarn machine automatically stops, the artificial sub-twist, tie twist, knot, loosen the yarn frame, remove the yarn

- Q: There are several yarns of textile mills

- Blended yarn Blended yarn is made of two or more fibers spinning yarn, such as polyester and cotton blended yarn, wool and viscose blended yarn. Such yarns are used to highlight the fabric of the advantages of both fibers. According to the thickness of yarn 1. A fine yarn of 32 or more (18 in. And below). Such yarns are suitable for thick fabrics such as tweeds and coarse fabrics

- Q: How good is the textile economy?

- Unhealed tension of the yarn: As the distance between the cheese and the creel, the yarn is unwound due to the self-weight of the yarn and the friction force of the yarn when it is unwound. The high-speed operation produces the centrifugal force, The unwinding tension of the yarn.

- Q: How to choose the twist of the roving?

- Roving with large twist, must be appropriate to enlarge the spine after the interval, the appropriate increase in roller pressure, so as not to stretch the spinning frame due to increased drawing force and roller slip, a hard head.

- Q: Cotton cotton yarn consumption of cotton how much?

- Cotton carded yarn consumption of cotton fixed: 1.08 tons / ton yarn; cotton yarn per ton of finished yarn 0.926 tons.

- Q: Forming Principle of Yarn of Textile Industry

- But the formation of the mechanism is the same, are controlled by the ladle up and down, spinning the speed of Rao Rao is generally the same.

Send your message to us

Recycled polyester yarn FDY Brightraw white color polyester monofilament yarn

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords