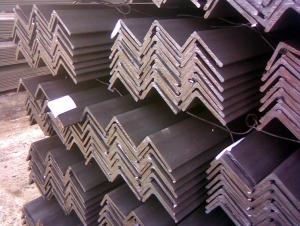

Unequal Angle

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Stainless Steel Angles

1.Grade: SS200,300,400 series

2.Size: 25×25×3 mm-100×100×10mm

3.Process: HRAP

4. Length: 2-6m

5. Shape: Equal

6. Delivery: within 20 days

7. MOQ: 1 ton

8. Certificate: ISO 9001:2008, SGS

9. Package:Standard Export Packing, or put into wooden boxes according to your

requirement

10. Application: Construction, Marine, Industry and so on

Name | Stainless Steel Angles | ||||||

Standard | ASTM A554, A312, A249, A269 and A270 | ||||||

Material Grade | 304,316,201,202, 316L,430 | ||||||

Length | 6m or as customers' request | ||||||

Tolerance | a) thickness: +/-0. 15mm | ||||||

| |||||||

b) Length:+/-4. 5mm - 0mm | |||||||

Surface | 180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | ||||||

Application | Decoration construction, upholstery, industry instruments | ||||||

Test | Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | ||||||

Chemical Composition of Material |

Composition

Material | 201 | 202 | 304 | 316L | 430 | |

C | ≤0.15 | ≤0.15 | ≤0.08 | ≤0.08 | ≤0.12 | ||

Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ||

Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤1.00 | ||

P | ≤0.06 | ≤0.06 | ≤0.045 | ≤0.045 | ≤0.040 | ||

S | ≤0.03 | ≤0.03 | ≤0.030 | ≤0.030 | ≤0.030 | ||

Cr | 16-18 | 17-19 | 18-20 | 16-18 | 16-18 | ||

Ni | 3.5-5.5 | 4-6 | 8-10.5 | 10-14 |

| ||

Mo |

|

|

| 2.0-3.0 |

| ||

Mechanical Property | Material Item | 201 | 202 | 304 | 316L | ||

Tensile Strength | ≥535 | ≥520 | ≥520 | ≥520 | |||

Yield Strength | ≥245 | ≥205 | ≥205 | ≥205 | |||

Extension | ≥30% | ≥30% | ≥35% | ≥35% | |||

Hardness (HV) | <253 | <253 | <200 | <200 | |||

- Q: How are steel angles used in structural framing?

- Structural framing relies heavily on the utilization of steel angles to ensure support and stability for various building components. These angles, characterized by their L-shaped form, serve to connect and reinforce different elements within a structure, including beams, columns, and trusses. A primary function of steel angles in structural framing is to enhance the strength and rigidity of beams and columns. By affixing steel angles to the sides of these components, they function as braces, effectively preventing buckling or bending under heavy loads. This becomes particularly crucial in large-scale construction projects, where the overall structural integrity of the building is of utmost importance. Moreover, steel angles find application in establishing connections between different structural members. For instance, they can be utilized to securely join beams with columns, ensuring a steadfast and stable joint. Typically, the angles are either bolted or welded to both members, resulting in a resilient and long-lasting connection. In addition to their role in connections, steel angles can also be employed to create frameworks for walls, roofs, and floors. By attaching angles to the top and bottom of these components, a robust framework is established, capable of supporting the weight of the structure above and providing stability throughout the construction process. To summarize, steel angles are indispensable in structural framing due to their ability to provide support, reinforce connections, and establish stable frameworks. Their versatility and strength render them an essential component within the construction industry.

- Q: What are the different connection methods for steel angles?

- There are several different connection methods for steel angles, depending on the specific application and structural requirements. Some common connection methods include: 1. Welding: Welding is one of the most common methods used to connect steel angles. It involves melting the adjacent surfaces of the angles and fusing them together using a welding electrode. This method provides high strength and rigidity but requires skilled labor and specialized equipment. 2. Bolting: Bolting is another widely used method for connecting steel angles. It involves fastening the angles together using bolts and nuts. Bolting offers the advantage of being easily adjustable and removable, making it suitable for situations where disassembly may be required. 3. Riveting: Riveting is a traditional method of connecting steel angles. It involves inserting a metal rivet through holes in the angles and then deforming the end to secure it in place. Riveting provides a strong and permanent connection but can be time-consuming and labor-intensive. 4. Adhesive bonding: Adhesive bonding is a modern method of connecting steel angles. It involves applying a high-strength adhesive to the contact surfaces of the angles and then joining them together. This method offers the advantage of being lightweight, flexible, and resistant to corrosion. 5. Mechanical fasteners: There are various mechanical fasteners available for connecting steel angles, such as self-tapping screws, self-drilling screws, and blind rivets. These fasteners provide a quick and easy way to connect angles without the need for additional tools or equipment. It is important to consider factors such as load requirements, structural stability, corrosion resistance, and ease of installation when selecting the appropriate connection method for steel angles.

- Q: What are the different types of steel angles?

- A variety of steel angles exist, each serving specific purposes and applications. Here are some common types: 1. Equal angle: Utilized for structural support, bracing, and framing in construction, this angle boasts equal sides. 2. Unequal angle: Also known as L-shaped or unequal leg angle, it features unequal sides, with one side longer than the other. It finds use in building construction for creating corners, edges, and supports. 3. Stainless steel angle: Crafted from stainless steel, this angle offers exceptional resistance to corrosion. It is commonly employed in environments exposed to moisture or chemicals, such as marine settings or food processing facilities. 4. Galvanized angle: These steel angles are coated with a layer of zinc to safeguard against rust and corrosion. They are frequently utilized in outdoor and industrial settings where durability is crucial. 5. Slotted angle: Equipped with holes or slots along its length, this steel angle facilitates easy attachment and adjustment of components. It is commonly found in shelving systems, storage racks, and DIY projects. 6. Rolled steel angle: Manufactured by rolling steel into a specific shape, it results in a smooth and uniform surface. Rolled steel angles are often employed in manufacturing, machinery, and structural applications. 7. Structural angle: Designed to bear heavy loads and provide structural support, these steel angles are prevalent in building frames, bridges, and other infrastructure projects. These examples represent only a fraction of the diverse range of steel angles available. The selection of the appropriate angle depends on various project requirements, such as load capacity, corrosion resistance, and aesthetic considerations. Seeking advice from professionals or structural engineers can aid in determining the most suitable type of steel angle for a specific application.

- Q: What's the chemical reaction between stainless steel and galvanized angle iron?

- Stainless steel and galvanized steel angle, if it is bolted, it is best to add non absorbent insulation gasket.

- Q: How are steel angles protected against UV degradation?

- Various methods can be employed to protect steel angles from UV degradation. Applying a protective coating or paint onto the surface of the steel angles is a common approach. These coatings typically contain UV inhibitors that shield against the harmful effects of ultraviolet rays. By absorbing or reflecting the UV radiation, the inhibitors reduce the potential for degradation. Another method is to galvanize the steel angles by coating them with a layer of zinc. This not only provides corrosion resistance but also offers some protection against UV radiation. Zinc possesses natural UV-blocking properties, which aid in minimizing the effects of UV degradation. In addition to coatings and galvanization, utilizing weather-resistant materials during the manufacturing process is another technique. These materials are specifically designed to withstand UV exposure and effectively safeguard the steel from degradation over time. Regular maintenance and inspections are essential to ensure ongoing protection against UV degradation. This includes cleaning the steel angles to remove dirt and debris that may trap moisture and hasten degradation. Periodic reapplication of coatings or touch-ups should also be performed to ensure long-term protection against UV radiation. In conclusion, a combination of protective coatings, galvanization, the use of weather-resistant materials, and proper maintenance can effectively protect steel angles from UV degradation.

- Q: What are the design considerations for incorporating steel angles into a structure?

- When incorporating steel angles into a structure, several design considerations need to be taken into account. First and foremost, the load-bearing capacity of the steel angles must be carefully assessed to ensure they can support the intended loads. The dimensions and thickness of the angles should be determined based on the structural requirements and anticipated stress levels. Additionally, the connection details between the steel angles and other structural elements need to be carefully designed to ensure they provide sufficient strength and rigidity. Considerations should include the type of fasteners, welding techniques, and any additional reinforcement required to achieve the desired structural integrity. Furthermore, factors such as corrosion protection, fire resistance, and durability should also be considered during the design process. Appropriate measures should be taken to prevent rust and corrosion on the steel angles, such as applying protective coatings or using stainless steel. Fire-resistant coatings or fireproofing materials may also be necessary, depending on the building's fire safety requirements. Lastly, aesthetics and architectural considerations may come into play when incorporating steel angles into a structure. The design should take into account the desired visual appearance, whether the angles will be exposed or concealed, and how they will integrate with the overall architectural style. In conclusion, the design considerations for incorporating steel angles into a structure involve assessing load-bearing capacity, connection details, corrosion protection, fire resistance, durability, and aesthetic integration.

- Q: What is the maximum length of a steel angle available in the market?

- The maximum length of a steel angle available in the market can vary depending on the supplier and the specific type of steel angle being referred to. However, in general, steel angles are typically available in lengths ranging from 20 feet (6.1 meters) to 40 feet (12.2 meters). It is important to note that these lengths are commonly found for standard steel angles, but there may be customized options available that could exceed these lengths if required for specific projects or applications. It is advisable to consult with the supplier or manufacturer to determine the maximum length available for a particular steel angle.

- Q: What are the advantages of using steel angles?

- There are several advantages of using steel angles. Firstly, steel angles provide excellent structural support due to their high strength and durability. They can withstand heavy loads and extreme weather conditions, making them ideal for construction projects. Additionally, steel angles are versatile and can be easily fabricated, cut, and welded to meet specific design requirements. They are also cost-effective, as they have a long lifespan and require minimal maintenance. Lastly, steel angles offer great aesthetic appeal, making them a popular choice for architectural applications.

- Q: Are steel angles resistant to earthquakes?

- Seismic-resistant construction can be achieved by utilizing steel angles, which possess high strength and ductility, making them suitable for this purpose. Often referred to as steel L-shaped beams, these steel angles are commonly employed in structural applications to provide support and reinforcement. During an earthquake, the utilization of steel angles aids in the even distribution of seismic forces throughout the structure, thereby reducing the occurrence of concentrated stress points. The L-shape design of these steel angles allows them to effectively resist bending and twisting forces, which are frequently encountered during seismic events. Moreover, steel angles can be interconnected and welded together to establish a rigid frame system, thereby enhancing their capability to withstand seismic forces. Such a system effectively absorbs and dissipates energy resulting from vibrations caused by earthquakes, ultimately minimizing any potential damage inflicted upon the structure. Nevertheless, it is crucial to acknowledge that the overall seismic resistance of a structure is contingent upon several factors, including its design, construction methods, and adherence to building codes and regulations. While steel angles alone cannot ensure complete protection against earthquakes, their integration into a well-designed seismic-resistant system significantly augments the structure's capacity to withstand seismic forces.

- Q: What are the different shapes available for steel angles?

- Steel angles come in various shapes, each serving a specific purpose in construction and structural applications. The most common shapes include the following: 1. Equal angles: These angles have legs of equal length and are formed by bending a single piece of steel. They find common use in general structural applications, such as supporting beams and columns. 2. Unequal angles: As the name suggests, these angles have legs of unequal length. They are often employed when one leg needs to be longer or shorter than the other. In construction, they provide additional strength and support in various applications. 3. L-shaped angles: These angles have one leg longer than the other, creating an L-shape. They are frequently used to reinforce corners and edges of structures, offering extra strength and support. 4. T-shaped angles: These angles have a longer leg that extends perpendicular to a shorter leg, forming a T-shape. They are commonly utilized as lintels or beams to support loads above openings like doors and windows. 5. C-shaped angles: These angles have one side curved inward, resulting in a C-shape. They are often employed in situations where the angle needs to fit around a curved or rounded surface, providing structural support and reinforcement. In summary, the availability of various steel angle shapes enables a wide range of applications in construction and structural engineering. They offer strength, support, and versatility in numerous projects.

Send your message to us

Unequal Angle

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords