New Model FDY optical white polyester yarn with best service

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic info

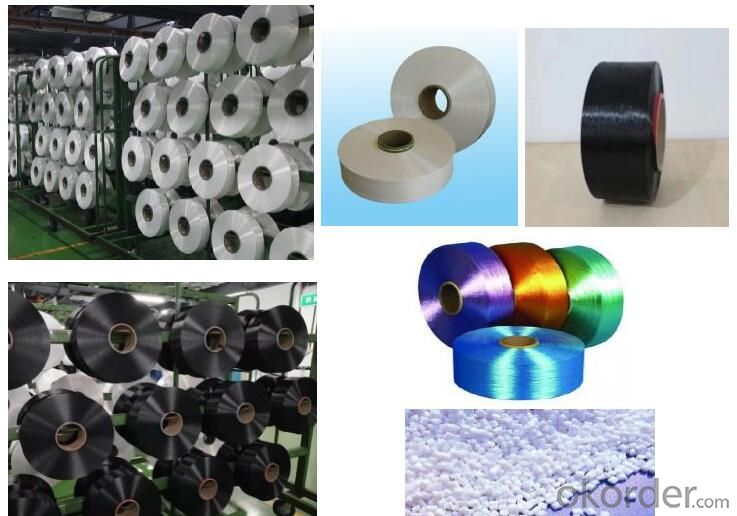

Product name: FDY 1000D HIGH TENACITY INDUSTRIAL YARN

Material: 100% Polyester

Pattern: dope-dyeing

Yarn Type: FDY, Filament

Feature: Eco-Friendly, Recycled, High Tenacity

Use: Weaving, Knitting, Sewing , Weaving , Knitting

Twist: S/Z TWIST

Evenness: EVEN

Color: white , black

MOQ: 30 KGS

Quality: AA Grade

Package: Pallet

Package Type: 4bobbins/carton, 10KG/bobbin, 40KG/cartons, 12 tons/20gp, 24 tons/40HQ

Certification: GRS, TC, OEKO

Keywords: Recycled FDY yarn, R-pet yarn, Eco-Friendly yarn

Specification: 50D/24F~144F, 75D/36F~144F, 100D/36F~288F, 150D/36F~288F, 200D/72F~288F, 300D/72F~576F, 450D/144F, 450D/192F, 600D/144F, 600D/192F or as per customers customized, single or double

Application: THE APPLICATION OF HIGH TENACTIY YARN IS FOR SLING, CONVEYOR BELT, GEOGRID, GEOTEXTILE, YARN-COATING, ROPE, SEWING THREAD, WEBBING, TIE DOWN, NETTING, HOSES, TEXTILENE, ETC.

Payment: T/T, LC

Supply Ability: 4000 Metric Ton/Metric Tons per Month

Production Facilities of FDY Yarn

We have the most advanced production system DSC. The whole production process is conducted and supervised by the operating platform. Meanwhile, there are 10 TMT fully automatic winding machine and Robot packaging system which highly improves the production efficiency and avoids manual mistakes.

Production Capacity of FDY Yarn

The production capacity is 200,000 TONS per year for now and it will be of 500,000 per year after the erection of the second production line.

- Q: What is the cheese yarn?

- So that the length of the yarn to take over and remove the yarn defects and impurities in the winder through the tank or the reciprocating guide yarn rewinding into the boundless or side, and into a certain shape (such as conical, Shape), a certain volume of the winding volume of the tube

- Q: What is the difference between textile sizing and paper making?

- The modified starch used in papermaking is mainly: acid modified starch (surface sizing), oxidized starch (surface sizing, coating), phosphate starch (surface sizing, coating), oxidized acetate starch (coating) Cationic starch, amphoteric starch (pulp added), grafted starch (coated. Market less) a technology is not up to standard, and then a cost can not accept

- Q: What is the textile bobbin?

- The textile bobbin is a tubular body whose inner hole is matched with the spinning machine spindle, characterized in that the bobbin tube wall has a plurality of holes.

- Q: What is the reason why the textile yarns are yarn

- Fine is the most widely used wool varieties, whether it is infants, children, women or men's clothing can be used for such rough wool weaving, weaving pattern fine and elegant.

- Q: There are several yarns of textile mills

- This type of yarn for high-grade fine fabrics, such as high-shirt, worsted sweater and so on. According to the spinning system. Spinning yarn Worsted yarn, also known as combed yarn, refers to yarns that are spun by combing processes, including combed cotton yarns and combed yarns. The fibers are parallel to the fiber in a high degree of straightness, smooth, smooth, but higher cost, higher yarn count. Combed yarn is mainly used for high-grade fabrics and knitwear raw materials, such as fine spinning, gabardine it, tweed, sweater and so on.

- Q: How to choose the twist of the roving?

- The roving strength increases with the increase of the roving coefficient, and the roving twist factor is increased to reduce the production efficiency of the roving machine, but it can increase the strength of the roving, reduce the roving elongation and improve the quality of the roving.

- Q: Textile spinning workshop car car summary and plan

- Summary, is a time period of the situation to conduct a comprehensive and systematic overall evaluation, total analysis, analysis of results, lack of experience and so on. Summary is the application of a writing, is done on the rational thinking of the work done

- Q: What is the difference between mesh cloth and Bali yarn?

- It has a unique elasticity function. Mesh fabric mesh structure, in the production process after a high temperature stereotypes, when subjected to external forces, can follow the direction of force extension, when the pull force to reduce the withdrawal, the mesh can be restored to the original shape. Mesh cloth is made of tens of thousands of polymer synthetic fiber yarn, refined from the oil out. Made of knitted weave, it is not only firm, able to withstand high strength of the tension and tear.

- Q: What is yarn support?

- Yarn count is the yarn count, divided into metric and imperial count.

- Q: How to reduce the cost of textile yarn dyeing

- First analyze your cost structure: Dyeing auxiliaries, labor (including management), water and electricity, equipment

Send your message to us

New Model FDY optical white polyester yarn with best service

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches