Equal Angle steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

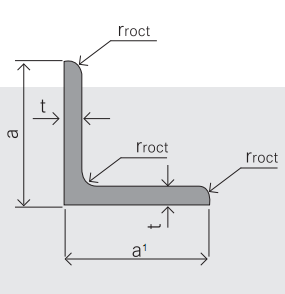

Specifications of Equal Angle

1. Standards: GB,ASTM,BS,AISI,DIN,JIS

2. Length:6m,9m,12m

3. Material:Material: GB Q235B, Q345B or Equivalent; ASTM A36; EN 10025, S235JR, S355JR; JIS G3192, SS400;

SS540.

4. Sizes:

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Chemical data: %

C | Mn | S | P | Si |

0.14-0.22 | 0.30-0.65 | ≤0.050 | ≤0.045 | ≤0.30 |

Usage & Applications of Equal Angle

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

- Q: What is the minimum thickness for a steel angle beam?

- The minimum thickness for a steel angle beam would depend on various factors, including the specific load requirements and design specifications. It is essential to consult engineering guidelines and structural design codes to determine the appropriate minimum thickness for a steel angle beam in a given application.

- Q: How are steel angles measured and labeled?

- Steel angles are measured and labeled based on their dimensions and properties. The measurements of a steel angle include its leg length, thickness, and weight per foot. The labeling typically follows a standard format, such as LxWxT, where L represents the leg length, W represents the width, and T represents the thickness.

- Q: Can steel angles be used in the construction of conveyor systems?

- Certainly! Conveyor systems can utilize steel angles for their construction. These angles are frequently employed as structural elements in conveyor systems owing to their robustness, resilience, and adaptability. They can effectively offer support, reinforcement, and steadiness to the conveyor structure. By welding or bolting steel angles together, a firm framework for the conveyor system can be easily fashioned. Furthermore, steel angles can be utilized to produce adjustable legs or brackets to accommodate diverse conveyor heights and angles. Additionally, these angles can be tailored and fabricated to meet precise design specifications, rendering them an ideal selection for constructing conveyor systems.

- Q: What is the maximum deflection for a steel angle beam?

- The maximum deflection for a steel angle beam depends on several factors including the dimensions of the beam, the material properties of the steel, and the applied load. It is calculated using engineering principles and can be determined using formulas and calculations specific to the beam's geometry and loading conditions. Therefore, without specific information about these factors, it is not possible to provide a definitive answer to the maximum deflection of a steel angle beam.

- Q: Can steel angles be used as bracing elements?

- Indeed, steel angles have the capability to serve as bracing elements. Construction and engineering projects frequently employ steel angles due to their robustness and longevity. These angles are commonly utilized to furnish structural support and stability, including as bracing elements. A rigid and secure bracing system can be established by either bolting or welding steel angles to other structural components. The design of these angles, with their L-shape, facilitates easy attachment to other members, thus imparting additional strength and resilience against lateral forces like wind or seismic loads. In summary, steel angles are a dependable choice for bracing elements across a wide range of applications, encompassing buildings, bridges, and industrial structures.

- Q: What is the maximum length for a curved steel angle?

- Several factors, such as the diameter of the curve, the steel thickness, and the project's specific requirements, determine the maximum length of a curved steel angle. Typically, the length can range from a few inches to several feet. However, it is crucial to seek guidance from a structural engineer or manufacturer to ensure the angle's structural integrity is not compromised. The manufacturing process and available equipment may also influence the achievable maximum length for a curved steel angle.

- Q: Can steel angles be used for staircases?

- Certainly! Steel angles are indeed suitable for the construction of staircases. Their strength and durability make them a popular choice in the field of construction. In terms of staircases, steel angles are frequently employed as stringers or support beams to ensure structural stability. They play a crucial role in establishing the framework or skeleton of the staircase, supporting the steps and providing a secure footing for individuals. Steel angles possess a high level of versatility and can be readily tailored and fabricated to meet the precise design specifications of staircases. Furthermore, their resistance to corrosion renders them suitable for both indoor and outdoor staircases.

- Q: What is the maximum slope for a steel angle?

- The maximum slope for a steel angle depends on various factors such as the size, shape, and thickness of the angle. However, in general, steel angles are designed to withstand vertical loads and provide stability in structural applications. Therefore, the maximum slope for a steel angle is typically limited to angles less than 45 degrees. Going beyond this angle may compromise the structural integrity of the angle and increase the risk of failure. It is important to consult engineering codes, standards, and specifications to determine the specific maximum slope for a particular steel angle in a given application.

- Q: Can steel angles be painted or coated?

- Steel angles have the capability to be painted or coated, which can yield numerous advantages including protection against corrosion, improved aesthetics, and increased durability. It is crucial to thoroughly clean and prepare the surface of the steel angles prior to painting or coating to ensure proper adhesion of the paint or coating. This typically involves eliminating any rust, grease, or dirt and applying an appropriate primer. Once the surface is adequately prepared, a range of paints or coatings can be utilized, such as epoxy, polyurethane, or powder coatings. The selection of paint or coating will depend on the specific requirements of the application, such as the desired level of corrosion resistance or appearance. In conclusion, painting or coating steel angles is a widely practiced technique to enhance their performance and extend their lifespan.

- Q: What are the different types of corrosion that can affect steel angles?

- There are several types of corrosion that can affect steel angles, including: 1. Uniform corrosion: This is the most common type of corrosion and occurs when the entire surface of the steel angle corrodes evenly. It is typically caused by exposure to moisture and oxygen in the environment. 2. Pitting corrosion: Pitting corrosion is characterized by the formation of small pits or holes on the surface of the steel angle. It occurs when localized areas of the metal are exposed to more aggressive corrosive agents, such as chloride ions or acidic substances. 3. Galvanic corrosion: Galvanic corrosion happens when two different metals are in contact with each other in the presence of an electrolyte, such as water or saltwater. The more active metal (the anode) corrodes while the less active metal (the cathode) remains protected. 4. Crevice corrosion: Crevice corrosion occurs in confined spaces or crevices where stagnant water or moisture can accumulate. The lack of oxygen and the concentration of corrosive agents can lead to localized corrosion and degradation of the steel angle. 5. Filiform corrosion: This type of corrosion appears as thread-like filaments that form on the surface of the steel angle. It is typically caused by the presence of moisture and oxygen, as well as the presence of contaminants such as salts or organic compounds. 6. Stress corrosion cracking: Stress corrosion cracking occurs when a combination of tensile stress and a corrosive environment causes cracks to form in the steel angle. It can be particularly dangerous as it can lead to sudden and catastrophic failure of the structure. It is important to note that the severity and likelihood of each type of corrosion can vary depending on factors such as the environment, exposure to corrosive agents, and the quality of the steel angle itself. Regular inspection, maintenance, and appropriate protective coatings can help mitigate the effects of corrosion on steel angles.

Send your message to us

Equal Angle steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords