FDY polyester filament yarn raw white semi-dull

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

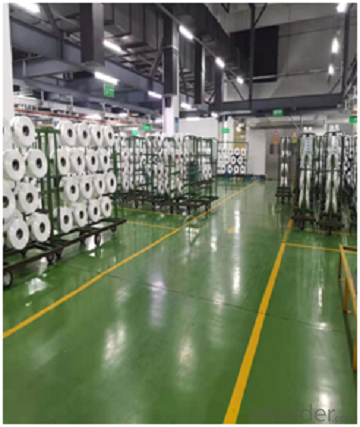

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of FDY Yarn

Material | 100% polyester |

Type | FDY (Fully Drawn Yarn), semidull |

Structure | Multifilament Yarn, Continuous Filament |

Color | White and Black |

Feature | Eco-Friendly, High Strength, |

Application | Knitting, Weaving, Sewing, Embroidery |

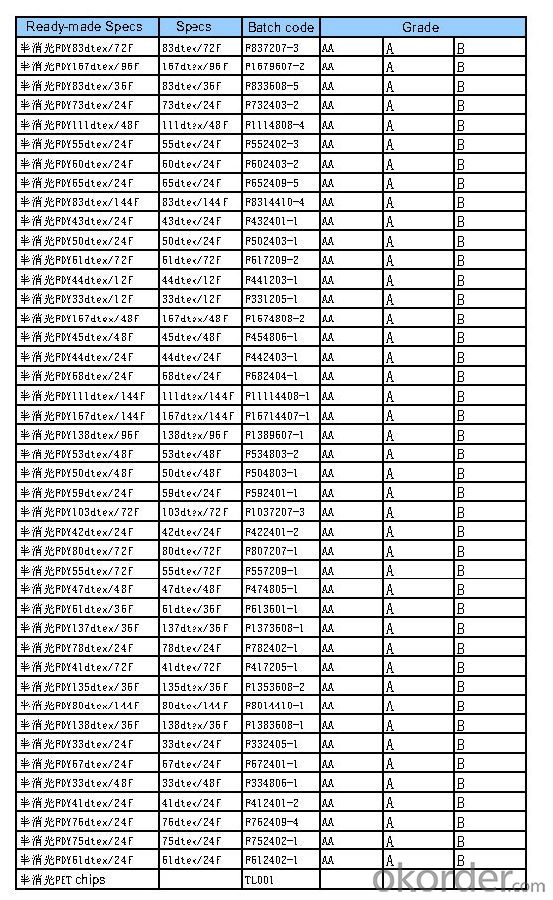

Specification | 11-167dtex, 12-144F |

Regular Specifications

Structure:

1). sheath-core structure: low melting polyester+polyester, Low melting polyester content:30%~40%

2). 100 pure low melting polyester

Feature:

Low melting polyester will be melted at 110/180 degree Celsius and be endowed with adhesive property.

Use low melting polyester is harmless, and enhances the strength of the fabric.

The fabric made with low melting polyester yarn is with high strength, washable, stiff and smooth, easy care.

Low melting polyester yarn owns good adhesiveness and stability, adhesive quickly.

The processing is simple, low energy consumption, nonhazardous, no pollution, Eco-friendly.

Application and suggestion:

1. The adhesive of two layers of sports shoe Upper material —FDY 50D/75D

2. Soft curtain, Zebra curtain, Roman curtain—FDY 75D/150D

3. Vertical blinds—FDY 250D

4. Filter net for air condition—FDY 30D/50D/75D/150D

5. Electromagnetic wire: PET-Glass fiber blended fiber—FDY 50D/75D

6. Garment lining cloth for suit, tie, hat, etc. —FDY 150D/50D/420D

7. Warp knitting fabric such as: Stiff mesh fabric, medical/food filter net, inner car decoration.

8. Top-grade eco-friendly filter material

9. Other applications: protective gloves, dust gauze, top-grade window screen, invisible screen, etc.

- Q: What is the difference between textile sizing and paper making?

- The modified starch used in textile pastes are: acid modified starch, oxidized starch, phosphate starch, acetate starch, carboxymethyl starch, grafted starch.

- Q: What is the textile bobbin?

- A plurality of holes are formed in the tube wall of the bobbin so that the cheese yarns wound around the bobbin are easily humidified by these holes.

- Q: Textile spinning yarn should be done first what to do

- Therefore, in the process with a single, if you can use some professional with a single tool, you will receive a multiplier effect. For example: with a single network, with a single industry with a wealth of information and professional foreign trade with the software to help enterprises solve the process with a single event, chores, trivial things, so easy with the single

- Q: There are several yarns of textile mills

- Usually, according to the yarn used in raw materials, yarn thickness, spinning method, spinning system, yarn structure and yarn use classification. According to the yarn raw material points 1. Pure spinning Pure spinning is a yarn made of a fiber material such as cotton yarn, wool yarn, hemp yarn and silk spinning. This type of yarn is suitable for making pure textile.

- Q: What is the textile fancy yarn theory?

- Common fancy yarn name and composition of the characteristics: 1, knot line, decorated yarn in the same place for many times twist back winding. 2, the spiral, by the fineness, twist and different types of two yarns combined and twisted to make. 3, thick section line, soft and thick fiber bundle attached to the core yarn, wrapped in solid yarn.

- Q: What is the yarn inside the textile industry is what kind of yarn?

- As for the thickness of the yarn, is to rely on weighing to determine. And the twist of the yarn, measured with a twist meter

- Q: Textile spinning workshop car car summary and plan

- Summary must have a brief overview of the situation and narrative, some relatively simple, some more detailed. Achievements and shortcomings. This is the main content of the summary. The purpose of the summary is to be sure to score and find out the shortcomings. What are the results, how big, what aspects of performance, how to obtain; the number of shortcomings, in what areas, how to produce, should be written clearly.

- Q: What is the reason why the yarn is spinning

- Spinning machine without insurance yarn, loom with a large circular machine, latitude and longitude knitting machine, the traditional shuttle weaving machine, etc.

- Q: What are the types of textile yarns?

- Artificial fiber: rayon (RAYON) also known as artificial cotton rayon (VISCOSE), blended fiber: long / short fiber blended yarn, there are T / RT / C two, with brightness: semi-light yarn / Triangular light yarn to processing points:

- Q: What is the yarn?

- 1, the choice of neutral detergent for cleaning; 2, to avoid vigorously rubbing lead to clothing deformation or material damage;

Send your message to us

FDY polyester filament yarn raw white semi-dull

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches