Eco-Friendly Polyester FDY Polypropylene Bright Dope Dyed Filament Yarn

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of FDY Yarn

Material | 100% polyester |

Type | FDY (Fully Drawn Yarn), semidull |

Structure | Multifilament Yarn, Continuous Filament |

Color | White and Black |

Feature | Eco-Friendly, High Strength, |

Application | Knitting, Weaving, Sewing, Embroidery |

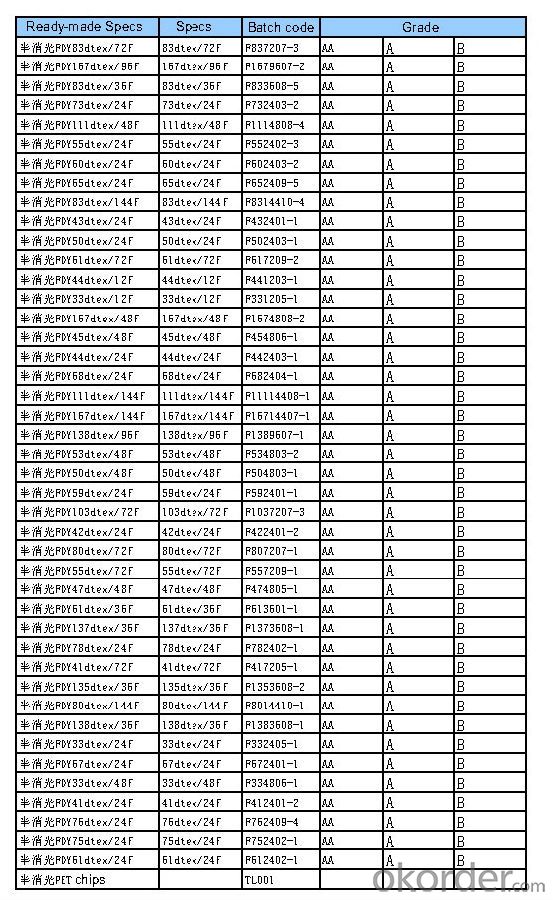

Specification | 11-167dtex, 12-144F |

Regular Specifications

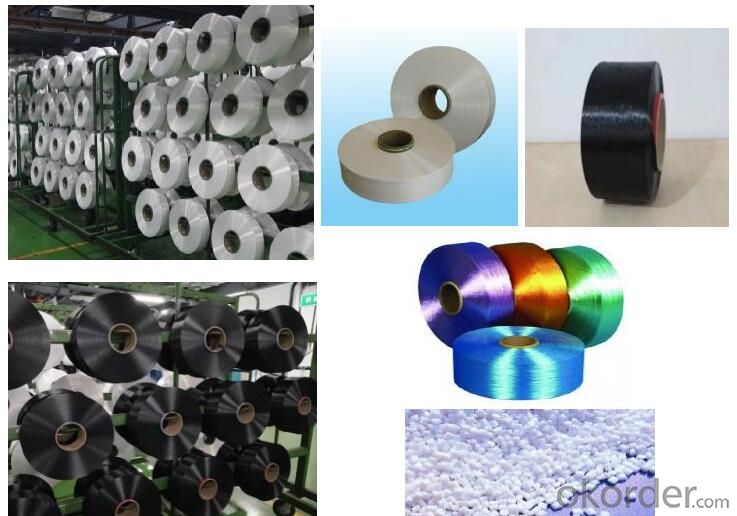

Production Facilities of FDY Yarn

We have the most advanced production system DSC. The whole production process is conducted and supervised by the operating platform. Meanwhile, there are 10 TMT fully automatic winding machine and Robot packaging system which highly improves the production efficiency and avoids manual mistakes.

Production Capacity of FDY Yarn

The production capacity is 200,000 TONS per year for now and it will be of 500,000 per year after the erection of the second production line.

Package of FDY Yarn

The FDY yarned is packed by plastic film, paper board, foam board and wooden pallets. Each pallets is about 640-720kg. Box package is also available.

Structure:

1). sheath-core structure: low melting polyester+polyester, Low melting polyester content:30%~40%

2). 100 pure low melting polyester

Feature:

Low melting polyester will be melted at 110/180 degree Celsius and be endowed with adhesive property.

Use low melting polyester is harmless, and enhances the strength of the fabric.

The fabric made with low melting polyester yarn is with high strength, washable, stiff and smooth, easy care.

Low melting polyester yarn owns good adhesiveness and stability, adhesive quickly.

The processing is simple, low energy consumption, nonhazardous, no pollution, Eco-friendly.

Advantage of Us:

Subsidiary of Stated-owned group, reliable and trustable

Industry leader in the PET chip and yarn fields

On time delivery and prompt response

Well-funded and accept different kinds of payment terms

- Q: Why in general the yarn in the woven fabric strength coefficient of use greater than 1

- 1. Processing cotton yarn manufacturing methods are more complex, in general, there are two kinds of spinning methods, that is, carded spinning and combing spinning. (1) carded spinning process: with cotton → open cotton → carding → parallel → roving → spun yarn → post-processing → finished product inspection. (2) combing spinning process: with cotton → open cotton → carding → strip → strip → combing → parallel → roving → spun yarn → post-processing → finished product inspection.

- Q: How does textile twist yarn identify?

- Different textile fibers, chemical composition is different, in the combustion process of course have different phenomena

- Q: 40s / 2 What does it mean, is this yarn 40 or 80?

- 21S / 1 x 40S / 2 means: 100% cotton fabric is 21S (count) / 1 (single stock) x 40S (count) / 2 (double

- Q: What is Artex and Artex Products?

- According to statistics, Japan, the United States, Germany, Canada and so are the generous consumption of yarn products, but also China's exports of major markets

- Q: What is the reason why the textile yarns are yarn

- Fine is the most widely used wool varieties, whether it is infants, children, women or men's clothing can be used for such rough wool weaving, weaving pattern fine and elegant.

- Q: What are the benefits of the steaming machine to the textile industry?

- (2) the yarn is soft and reduces the wear of the needle; (3) from the beginning to the roll forming, always maintain a balanced and the best friction value; (3)

- Q: What is the yarn inside the textile industry is what kind of yarn?

- Direct dye can be stained, is the natural fiber. And then go to the performance of the fiber, the dissolution test, to come to a certain type.

- Q: From the yarn to the finished textile fabric production process

- Is the famous American chemist Carothers and his research team invented. The main varieties of nylon are nylon 6 and nylon 66, accounting for the absolute dominant, followed by nylon 11, nylon 12, nylon 610, nylon 612, in addition to nylon 1010, nylon 46, nylon 7, nylon 9, nylon 13, Varieties are nylon 6I, nylon 9T and special nylon MXD6 (barrier resin) and so on

- Q: Cotton yarn downstream enterprises have what kind of

- Suggest you can find, textile mills, weaving plants, silk factory, industrial cloth factory, sewing factory, etc.

- Q: Is the thickness of the yarns 40S and 80S / 2 in the textile fabric the same?

- 80S is a special high, the price is much higher than the 40S, single yarn twist is much higher, after the stock it is much stronger than the 40S. As the twist to different, cloth style is also different

Send your message to us

Eco-Friendly Polyester FDY Polypropylene Bright Dope Dyed Filament Yarn

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches