Dope dyed black polyester fdy 100/36 600tpm twisted warp yarn in china

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info

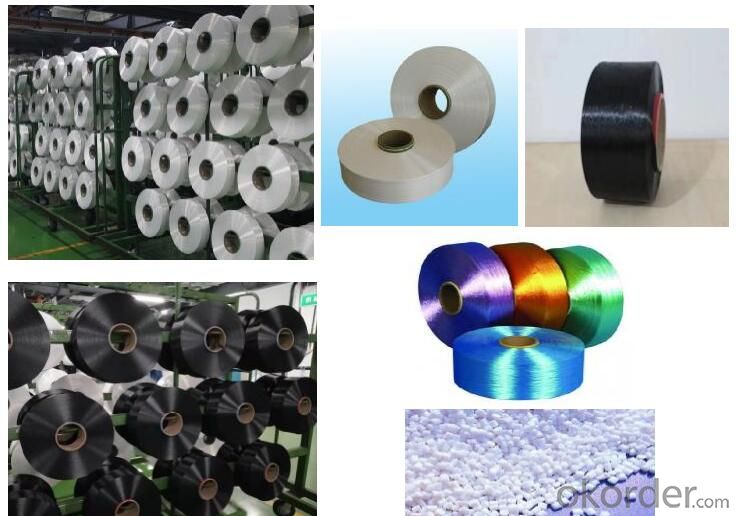

Product name: FDY 1000D HIGH TENACITY INDUSTRIAL YARN

Material: 100% Polyester

Pattern: dope-dyeing

Yarn Type: FDY, Filament

Feature: Eco-Friendly, Recycled, High Tenacity

Use: Weaving, Knitting, Sewing , Weaving , Knitting

Twist: S/Z TWIST

Evenness: EVEN

Color: white , black

MOQ: 30 KGS

Quality: AA Grade

Package: Pallet

Package Type: 4bobbins/carton, 10KG/bobbin, 40KG/cartons, 12 tons/20gp, 24 tons/40HQ

Certification: GRS, TC, OEKO

Keywords: Recycled FDY yarn, R-pet yarn, Eco-Friendly yarn

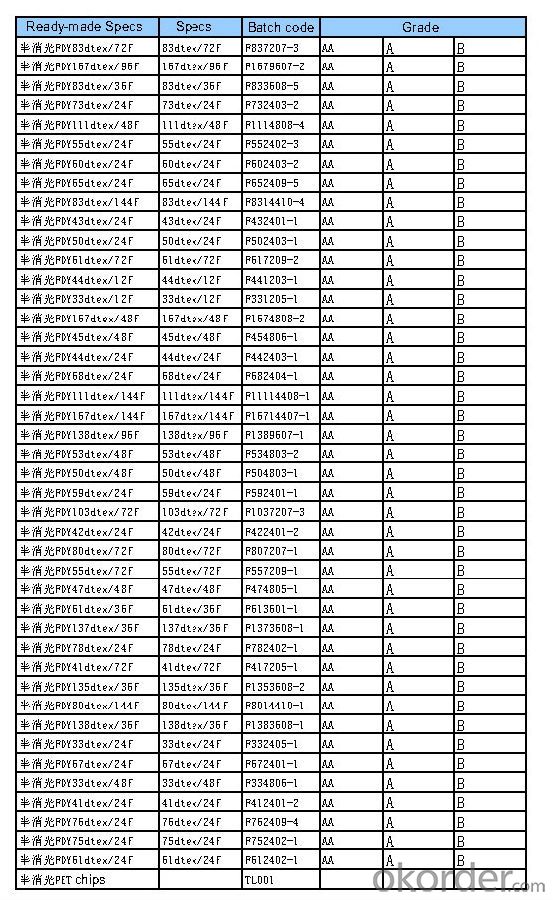

Regular Specifications

Feature:

Low melting polyester will be melted at 110/180 degree Celsius and be endowed with adhesive property.

Use low melting polyester is harmless, and enhances the strength of the fabric.

The fabric made with low melting polyester yarn is with high strength, washable, stiff and smooth, easy care.

Low melting polyester yarn owns good adhesiveness and stability, adhesive quickly.

The processing is simple, low energy consumption, nonhazardous, no pollution, Eco-friendly.

Application and suggestion:

1. The adhesive of two layers of sports shoe Upper material —FDY 50D/75D

2. Soft curtain, Zebra curtain, Roman curtain—FDY 75D/150D

3. Vertical blinds—FDY 250D

4. Filter net for air condition—FDY 30D/50D/75D/150D

5. Electromagnetic wire: PET-Glass fiber blended fiber—FDY 50D/75D

6. Garment lining cloth for suit, tie, hat, etc. —FDY 150D/50D/420D

7. Warp knitting fabric such as: Stiff mesh fabric, medical/food filter net, inner car decoration.

8. Top-grade eco-friendly filter material

9. Other applications: protective gloves, dust gauze, top-grade window screen, invisible screen, etc.

- Q: Why in general the yarn in the woven fabric strength coefficient of use greater than 1

- Introduction 1. Processing of cotton yarn manufacturing methods are more complex, in general, there are two kinds of spinning methods, that is, carded spinning and combing spinning. (1) carded spinning process: with cotton → open cotton → carding → parallel → roving → spun yarn → post-processing → finished product inspection. (2) combing spinning process: with cotton → open cotton → carding → strip → strip → combing → parallel → roving → spun yarn → post-processing → finished product inspection.

- Q: Textile spinning yarn should be done first what to do

- To solve the knowledge of the process with a single process and to provide a single process with a professional software system, making the merchandiser really from the complex with a single transaction freed, thereby improving the business with the single management level

- Q: Will the following kind of yarn which fine? A32 support, B21 support

- 32 branch is relatively small. "Count" is used to indicate the degree of textile fiber thickness of the unit, the higher the number that the fiber, the count is divided into the number of imperial and metric number

- Q: What is the reason for the low strength of cotton yarn

- We found in the spinning frame yarn problems, roving weight qualified, and later found in the apron with a plot of flowers, may affect the yarn less stretch.

- Q: Textile spinning workshop car car summary and plan

- Summary, is a time period of the situation to conduct a comprehensive and systematic overall evaluation, total analysis, analysis of results, lack of experience and so on. Summary is the application of a writing, is done on the rational thinking of the work done

- Q: Cotton cotton yarn consumption of cotton how much?

- Tons of yarn consumption of cotton "and the raw material grade and length and with the rate, equipment, technology, operation, and even with the spinning branch (Turks) and the workshop temperature and humidity are related to the amount of cotton consumption quota is as follows:

- Q: What is the diameter of a yarn of 40 yarns?

- The diameter of the yarn is related to the number of yarns (the number of cables in the linear density), the raw material and the twist. Commonly used approximation method to calculate the yarn diameter: cotton yarn diameter can be calculated using the following two methods:

- Q: From the yarn to the finished textile fabric production process

- Nylon is the most important engineering plastics, production in the top five general engineering plastics in the first place. Nylon [1], is a polyamide fiber (nylon) is a saying can be made of long fiber or staple fiber. Mercerized cotton: in accordance with the two mercerizing process division, mercerized cotton can refer to the yarn through the mercerized process of cotton yarn, but also through the fabric mercerized cotton fabric. Yarn mercerizing: refers to the cotton yarn in the case of tension, after the treatment of concentrated caustic soda, so that it has both the original characteristics of cotton, but also has a silk general luster of a special type of cotton yarn.

- Q: How to reduce the cost of textile yarn dyeing

- 3, water and electricity state control, you can not save 4, the equipment is the previous, and now do not expand the scale, for the time being

- Q: What is the yarn in the textile

- Cloth clip yarn can be seen to the naked eye.

Send your message to us

Dope dyed black polyester fdy 100/36 600tpm twisted warp yarn in china

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords