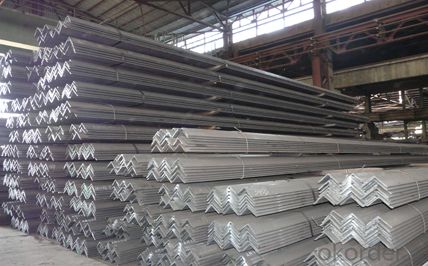

Equal / L Shaped / Unequal Mild Steel Angle Iron

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering Equal / L Shaped / Unequal Mild Steel Angle Iron at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Equal / L Shaped / Unequal Mild Steel Angle Iron are ideal for structural applications and are widely used a variety of architectural and engineering structures, such as beams, bridges, ship; transmission tower, reaction tower; lifting transportation machinery; industrial furnace; container frame, warehouse goods shelves, etc

Product Advantages:

OKorder's Equal / L Shaped / Unequal Mild Steel Angle Iron are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M/12M |

30 | 30 | 2.5---4.0 | 6M/12M |

38 | 38 | 2.5 | 6M/12M |

38 | 38 | 3.0---5.0 | 6M/12M |

40 | 40 | 3.0---6.0 | 6M/12M |

50 | 50 | 3 | 6M/12M |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

90 | 90 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Images:

- Q: How do steel angles perform under seismic loads?

- Steel angles are widely used in construction to provide support and reinforcement for structures. Their inherent properties and design flexibility make them highly effective in seismic conditions. A major advantage of steel angles is their impressive strength-to-weight ratio. This enables them to withstand the intense forces and movements caused by earthquakes without significant deformation or failure. The angle's compact shape also helps distribute the load efficiently, reducing stress concentrations and potential weak points. Furthermore, steel angles can be easily connected to other structural elements, creating a robust and reliable connection system. This is crucial in seismic design, where the ability to transfer forces and accommodate movements is vital. To further enhance their performance under seismic loads, steel angles can be designed with specific features. For example, the addition of stiffeners or bracing elements can increase their resistance to lateral forces, minimizing the risk of buckling or collapse. Using thicker and stronger steel grades can also improve their capacity to absorb and dissipate seismic energy. Various seismic design codes and standards provide guidelines and requirements for the use of steel angles in earthquake-resistant structures. These codes consider factors such as maximum stress levels, connection details, and overall structural behavior during seismic events. In conclusion, steel angles excel in seismic conditions due to their high strength-to-weight ratio, efficient load distribution, and design flexibility. When properly designed and implemented, they effectively withstand the forces and movements generated during earthquakes, ensuring the structural integrity and safety of buildings.

- Q: What is the maximum allowable torsional buckling stress for a steel angle?

- The maximum allowable torsional buckling stress for a steel angle depends on several factors, including the material properties of the steel, the geometry of the angle, and the applied load conditions. In general, torsional buckling occurs when a member twists under an applied torque, resulting in a loss of stability and potential failure. To prevent torsional buckling, design codes and standards provide guidelines and formulas to determine the maximum allowable stress. For example, the American Institute of Steel Construction (AISC) provides a formula for the calculation of torsional buckling stress in their Steel Construction Manual. This formula takes into account the section properties of the angle, such as the moment of inertia and the radius of gyration, along with the slenderness ratio and the effective length of the member. It is important to note that the maximum allowable torsional buckling stress varies depending on the specific design requirements and safety factors used in the design process. Therefore, it is essential to refer to the relevant design codes and consult with a structural engineer to determine the specific maximum allowable torsional buckling stress for a given steel angle in a particular design situation.

- Q: Do steel angles require maintenance?

- Yes, steel angles do require maintenance. While steel is a durable material, it is still susceptible to rust and corrosion, especially when exposed to moisture or harsh environmental conditions. Regular maintenance is necessary to prevent these issues and ensure the longevity of steel angles. Some common maintenance practices include inspecting for any signs of rust or damage, cleaning the surface to remove dirt and debris, and applying protective coatings or paints to prevent corrosion. Additionally, proper storage and handling of steel angles can also contribute to their maintenance. It is important to follow manufacturer guidelines and consult with professionals to determine the specific maintenance requirements for steel angles in different applications.

- Q: Are steel angles suitable for constructing bridges?

- Yes, steel angles are suitable for constructing bridges. Steel angles offer excellent strength, durability, and versatility, making them a popular choice in bridge construction. They can be used to provide structural support, enhance stability, and distribute load effectively, ensuring the bridge's overall integrity and safety.

- Q: Are steel angles available in non-standard dimensions?

- Yes, steel angles are available in non-standard dimensions.

- Q: Can steel angles be used in high-temperature applications?

- Steel angles can be used in high-temperature applications depending on the specific alloy and the temperature range. Steel alloys that have been specifically designed for high-temperature applications, such as stainless steels or heat-resistant alloys, can withstand elevated temperatures without significant loss in strength or structural integrity. These alloys often contain elements like chromium, nickel, or molybdenum, which increase their resistance to corrosion, oxidation, and high temperatures. However, it is important to note that not all steel angles are suitable for high-temperature applications. Ordinary carbon steels, for example, have a limited temperature range before they start to lose strength and become susceptible to deformation or failure. The exact temperature limit for a specific steel angle will depend on factors such as the alloy composition, heat treatment, and the duration of exposure to high temperatures. In summary, steel angles can be used in high-temperature applications if they are made from appropriate alloys that are specifically designed for such conditions. It is crucial to consult with materials engineers or experts who can provide guidance on the suitable steel alloys and temperature limits for a given application to ensure safe and reliable performance.

- Q: How do steel angles contribute to the sustainability of a project?

- Steel angles contribute to the sustainability of a project in several ways. Firstly, steel angles are typically made from recycled steel, reducing the need for virgin materials. This helps to conserve natural resources and minimize the environmental impact of the project. Additionally, steel is one of the most recycled materials in the world, which means that at the end of the project's life cycle, the steel angles can be recycled again, further reducing waste and minimizing the project's carbon footprint. Secondly, steel angles are durable and long-lasting. They have high strength-to-weight ratios, allowing for efficient and cost-effective designs. This durability ensures that the project will have a long lifespan, reducing the need for frequent repairs or replacements. By avoiding premature replacements, the project can minimize waste and the associated environmental impact. Furthermore, steel angles are highly versatile and can be used in a wide range of applications. This versatility allows for efficient use of materials and the ability to adapt to changing needs or requirements. The use of steel angles can also contribute to the overall energy efficiency of a project. For example, steel angles can be used to create structural frames or support systems, which can help optimize the use of natural light and reduce the need for artificial lighting or heating. Lastly, steel angles are highly resistant to corrosion and weathering. This resistance ensures that the project's structural integrity is maintained over time, reducing the need for maintenance and repair activities. This not only saves costs but also minimizes the use of resources and energy associated with maintenance activities. In conclusion, steel angles contribute to the sustainability of a project by being made from recycled materials, being durable and long-lasting, offering versatility in design, and providing resistance to corrosion and weathering. By incorporating steel angles into a project, it is possible to reduce waste, conserve natural resources, optimize energy efficiency, and minimize the overall environmental impact.

- Q: How do you calculate the stability factor of a steel angle?

- The stability factor of a steel angle is calculated by dividing the Euler buckling load by the applied compressive load.

- Q: What are the typical lifespan and durability of steel angles?

- The typical lifespan and durability of steel angles can vary depending on various factors such as the quality of the steel, the environment in which they are used, and the level of maintenance they receive. However, steel angles are known for their excellent durability and long lifespan. In general, steel angles are designed to withstand heavy loads and provide structural support in various construction and industrial applications. They are commonly made from carbon steel or stainless steel, both of which are known for their strength and resistance to corrosion. When properly maintained and protected against corrosion, steel angles can last for several decades without significant deterioration. Regular maintenance practices such as cleaning, painting, and applying protective coatings can help extend their lifespan even further. The durability of steel angles is also influenced by the environment in which they are installed. In harsh environments with high levels of moisture, extreme temperatures, or exposure to chemicals, the lifespan may be shorter. However, proper corrosion protection measures can mitigate these effects and ensure a longer lifespan. It is worth noting that steel angles used in marine or offshore applications may have a shorter lifespan compared to those used in less corrosive environments. This is due to the constant exposure to saltwater and harsh weather conditions, which can accelerate corrosion. In summary, steel angles are known for their durability and can have a long lifespan if properly maintained and protected against corrosion. However, the specific lifespan can vary depending on factors such as the quality of the steel, environmental conditions, and maintenance practices.

- Q: Can steel angles be used for manufacturing ladders?

- Yes, steel angles can be used for manufacturing ladders. Steel angles are commonly used in ladder construction due to their strength and durability. They provide a sturdy framework and can withstand heavy loads, making them suitable for ladder applications. Steel angles also offer resistance to bending and twisting, ensuring stability and safety when climbing. Additionally, they can be easily welded or bolted together to create the desired ladder structure. Overall, steel angles are a reliable choice for manufacturing ladders.

Send your message to us

Equal / L Shaped / Unequal Mild Steel Angle Iron

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords