Equal Angle Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 80000-100000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

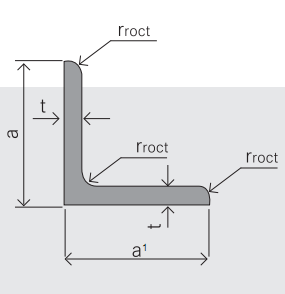

Specifications of Equal Angle Steel

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2.Length:6m,9m,12m

3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR,S355JR;JISG3192,SS400;SS540.

.

.

4.Sizes:

|

EQUAL ANGLES SIZES |

| ||

|

a(mm) |

a1(mm) |

thickness(mm) |

length |

|

25 |

25 |

2.5---3.0 |

6M/12M |

|

30 |

30 |

2.5---4.0 |

6M/12M |

|

38 |

38 |

2.5 |

6M/12M |

|

38 |

38 |

3.0---5.0 |

6M/12M |

|

40 |

40 |

3.0---6.0 |

6M/12M |

|

50 |

50 |

3 |

6M/12M |

|

50 |

50 |

3.7---6.0 |

6M/9M/12M |

|

60 |

60 |

5.0---6.0 |

6M/9M/12M |

|

63 |

63 |

6.0---8.0 |

6M/9M/12M |

|

65 |

65 |

5.0---8.0 |

6M/9M/12M |

|

70 |

70 |

6.0---7.0 |

6M/9M/12M |

|

75 |

75 |

5.0---10.0 |

6M/9M/12M |

|

80 |

80 |

6.0---10.0 |

6M/9M/12M |

|

90 |

90 |

6.0---10.0 |

6M/9M/12M |

|

100 |

100 |

6.0---12.0 |

6M/9M/12M |

|

120 |

120 |

8.0-12.0 |

6M/9M/12M |

|

125 |

125 |

8.0---12.0 |

6M/9M/12M |

|

130 |

130 |

9.0-12.0 |

6M/9M/12M |

|

140 |

140 |

10.0-16.0 |

6M/9M/12M |

|

150 |

150 |

10---15 |

6M/9M/12M |

|

160 |

160 |

10---16 |

6M/9M/12M |

|

180 |

180 |

12---18 |

6M/9M/12M |

|

200 |

200 |

14---20 |

6M/9M/12M |

5. Material details:

|

Alloy No |

Grade |

Element (%) |

|||||

|

C |

Mn |

S |

P |

Si |

|||

|

|

|

|

|

|

|

|

|

|

Q235 |

B |

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045 |

≤0.3 |

|

|

|

|

|

|

|

|

|

|

|

Alloy No |

Grade |

Yielding strength point( Mpa) |

|||||

|

Thickness (mm) |

|||||||

|

≤16 |

>16--40 |

>40--60 |

>60--100 |

||||

|

≥ |

|||||||

|

|

|

|

|

|

|

||

|

Q235 |

B |

235 |

225 |

215 |

205 |

||

|

Alloy No |

Grade |

Tensile strength (Mpa) |

Elongation after fracture (%) |

||||

|

Thickness (mm) |

|||||||

|

|

≤16 |

>16--40 |

>40--60 |

>60--100 |

|||

|

≥ |

|||||||

|

|

|

|

|

|

|

|

|

|

Q235 |

B |

375--500 |

26 |

25 |

24 |

23 |

|

Usage & Applications of Equal Anlge Steel

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Equal Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

- Q: Can steel angles be used for acoustic isolation or noise barriers?

- No, steel angles are not typically used for acoustic isolation or noise barriers as they do not possess the necessary properties to effectively block or absorb sound. Other materials such as acoustic panels or specialized barriers are more commonly used for this purpose.

- Q: Bearing capacity of angle steel and channel steel

- Angle called angle, the steel strip is perpendicular to each other on both sides into the corner. There are equal angles and unequal angles. The two sides of an equal angle steel are equal in width. The specifications are expressed in millimeters of edge width * edge width * edge thickness. Such as "/ 30 x 30 x 3", that is 30 mm width equal angle, edge thickness of 3 mm. Also available models that model is the number of centimeters wide, such as angle 3#. The model does not mean the size of the different edges and sizes of the same model. Therefore, the width, the edge and the thickness of the angle iron should be filled out in the contract and other documents, so as not to be indicated by the model alone. Standard Specification for hot-rolled equal angle iron is 2#-20#. The angle iron can be made up of different force components according to the different structure, and can also be used as the connecting piece between the components. Widely used in a variety of architectural and engineering structures, such as beams, bridges, towers, hoisting and conveying machinery, ships, industrial furnace, reaction tower, container frame and warehouse.Angle steel performance index: the performance test of angle iron is mainly tensile test and bending test. Indicators include yield point, tensile strength, elongation and bending compliance.

- Q: How do you connect steel angles together?

- There are several ways to connect steel angles together depending on the specific application and load requirements. Here are a few common methods: 1. Welding: The most common and effective method is to weld the steel angles together. This creates a strong and permanent connection. It is important to ensure proper welding techniques are followed to maintain the integrity and strength of the joint. 2. Bolting: Another method is to use bolts and nuts to connect the steel angles. This allows for easy disassembly and reassembly if required. It is important to use the correct size and grade of bolts to ensure the connection can withstand the intended loads. 3. Riveting: Rivets can also be used to connect steel angles together. This method provides a strong and permanent connection, but it requires specialized tools and expertise to properly install the rivets. 4. Adhesive bonding: In some cases, adhesive bonding techniques can be used to connect steel angles together. This method is usually used in conjunction with other fastening methods, such as welding or bolting, to provide additional strength and stability. When choosing the method to connect steel angles, it is important to consider factors such as the load requirements, environmental conditions, and expected lifespan of the structure. Consulting with a structural engineer or a professional in the field is recommended to ensure the best connection method is chosen for your specific application.

- Q: Can steel angles be used in residential construction?

- Yes, steel angles can be used in residential construction. Steel angles are commonly used as structural elements in residential buildings for various applications, such as supporting roof trusses, reinforcing walls, framing doorways, and constructing balconies. They provide strength, durability, and stability to the structure, making them a suitable choice for residential construction projects.

- Q: How does the price of steel angles vary based on size and grade?

- The price of steel angles can be affected by various factors, including the size and grade of the steel. When it comes to the size, larger angles are generally more expensive than smaller ones. This is because larger angles require more raw material and involve more manufacturing processes, resulting in higher production costs. As a result, as the size or length of the angle increases, so does its price. The grade of the steel also plays a role in determining the price. Steel angles come in different grades, each with its own characteristics and properties. Higher-grade steel angles, such as stainless steel or structural steel, tend to be more expensive compared to lower-grade options like mild steel. This is because higher-grade steels often require more advanced manufacturing techniques and superior quality raw materials, which contribute to higher production costs and, consequently, a higher price. Other factors that can impact the price of steel angles include market demand, the availability of raw materials, and manufacturing efficiency. Fluctuations in demand and supply can lead to price variations, with higher demand usually resulting in higher prices. Additionally, the availability and cost of raw materials used in the production of steel angles, such as iron ore and scrap metal, can affect the overall price. Lastly, advancements in manufacturing processes and technology can increase efficiency, potentially lowering production costs and influencing the final price of steel angles. To summarize, the price of steel angles is influenced by their size and grade. Larger angles and higher-grade steels tend to be more expensive due to increased production costs. Market demand, raw material availability, and manufacturing efficiency also play a role in determining the price of steel angles.

- Q: How do steel angles contribute to the durability of a structure?

- Steel angles contribute to the durability of a structure by providing additional strength and stability. They are used to reinforce connections and support load-bearing components, ensuring structural integrity and withstanding various forces such as gravity, wind, and seismic loads. The angle shape of the steel allows for efficient distribution of stress and prevents bending or deformation, enhancing the overall durability and longevity of the structure.

- Q: What are the different types of steel angles connections for roof trusses?

- Roof trusses commonly utilize different types of steel angle connections to ensure strong and stable support. These connections are crucial for maintaining the structural integrity of the roof. One frequently employed steel angle connection is the gusset plate connection. This method involves using triangular steel plates to connect the truss members at their intersection points. To establish a secure connection, these plates are typically welded or bolted to the steel angles. Another type of steel angle connection is the angle cleat connection. This approach relies on steel angles to connect the truss members using bolts or welding. These angles are usually bolted or welded to the top and bottom chords of the truss, adding strength and stability. A third option is the angle clip connection, which employs steel clips or brackets to connect the truss members at their intersection points. These clips are typically bolted or welded to the steel angles, creating a robust and secure connection. Lastly, there is the angle bracket connection. This type of connection involves using steel brackets or brackets to connect the truss members. The brackets are typically bolted or welded to the steel angles, providing a reliable and sturdy connection. In summary, various types of steel angle connections can be used for roof trusses, each offering distinct advantages and characteristics. The choice of connection depends on factors such as design requirements, load-bearing capacity, and construction methods.

- Q: How do steel angles perform under high temperatures?

- Due to their high melting point and exceptional heat resistance, steel angles exhibit excellent performance in high-temperature conditions. Steel, a widely utilized material in construction and engineering, is renowned for its robustness and durability. Steel angles, when subjected to elevated temperatures, maintain their structural integrity and do not easily deform or weaken. This is primarily due to steel's elevated melting point, typically ranging from 1370 to 1530 degrees Celsius (2500 to 2800 degrees Fahrenheit), enabling it to endure extreme heat without significant harm. Moreover, steel possesses outstanding heat resistance, enabling efficient heat dissipation and maintaining stability when confronted with high thermal loads. Consequently, steel angles are suitable for applications involving elevated temperatures, such as industrial furnaces, power plants, or high-temperature environments. However, it is crucial to acknowledge that the specific performance of steel angles under high temperatures can vary depending on the steel's grade and composition, as well as the intensity and duration of heat exposure.

- Q: Can steel angles be used as bracing elements in buildings?

- Bracing elements in buildings can indeed consist of steel angles. These angles are frequently utilized in construction due to their impressive strength and versatility. Their primary function is to provide lateral stability and support to structures, making them essential structural components. By utilizing steel angles as bracing elements, buildings become capable of withstanding horizontal forces like wind or seismic activity, thus preventing excessive movement or deformation. These angles are typically placed at strategic points, such as corners or intersections, and can be securely connected to other structural members using bolts or welds. The preference for steel angles as bracing elements is justified by their advantageous features, including a high strength-to-weight ratio, durability, and ease of installation. Therefore, it can be confidently stated that steel angles are a reliable and commonly employed solution for bracing elements in buildings.

- Q: What are the different types of corrosion that can affect steel angles?

- There are several different types of corrosion that can affect steel angles, including general corrosion, pitting corrosion, crevice corrosion, galvanic corrosion, and stress corrosion cracking.

1. Manufacturer Overview

| Location | Tangshan, China |

| Year Established | 1996 |

| Annual Output Value | Above US$ 300 Million |

| Main Markets | Middle East; Korea; Southeast Aisa |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 70% - 80% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 900,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | Average |

Send your message to us

Equal Angle Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 80000-100000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords