Geocomposite Drain

Geocomposite Drain Related Searches

Geocomposite Wall Drain Geocomposite Subsoil Drain Geocomposite Drainage Material Geocomposite Drainage System Geocomposite Strip Drain Geocomposite Drainage Layer Geocomposite Drain Strips Geocomposite Drain Installation Geocomposite Drainage Net Geocomposite Sheet Drain Geocomposite Drainage Strip Geocomposite Drainage Mat Geocomposite Drainage Board Geocomposite Drainage Sheet Geocomposite Geocomposite Membrane Geocomposite Drainage Layer Cost Geocomposite Liner Geomembrane Drainage Composite Geomembrane Gse Geocomposite Geocomposite Clay Liner Composite Geogrid Composite Geogrid Machine Skaps Geocomposite Agru Geocomposite Conductive Geomembrane Geocomposite Definition Geomembrane Landfill Drainage FittingsGeocomposite Drain Supplier & Manufacturer from China

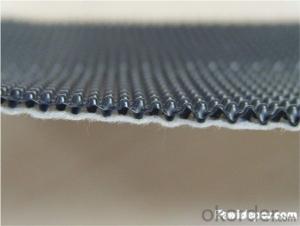

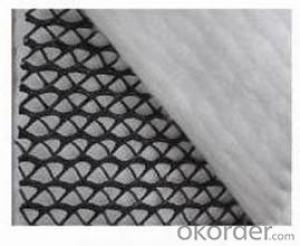

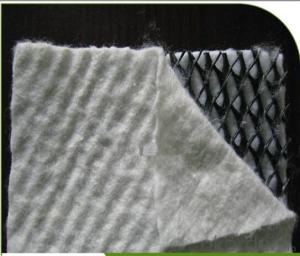

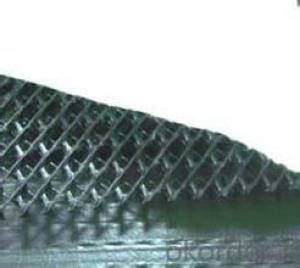

Geocomposite Drain is a specialized product that consists of geotextiles and geogrids, designed to provide efficient drainage and reinforcement in various civil engineering applications. These products are engineered to enhance the performance of soil structures by managing water flow and offering stability to the ground. They are particularly useful in applications such as road construction, slope stabilization, and retaining wall systems.The Geocomposite Drain finds its application in a wide range of scenarios where efficient water management and soil reinforcement are required. It is commonly used in projects involving the construction of roads and highways, where it helps to prevent water damage and maintain the structural integrity of the pavement. Additionally, it is employed in the stabilization of slopes and embankments, where it aids in the prevention of soil erosion and landslides. In retaining wall systems, the Geocomposite Drain enhances the stability of the structure by effectively managing water seepage and providing reinforcement to the soil behind the wall.

Okorder.com is a reputable wholesale supplier of Geocomposite Drain products, boasting a large inventory that caters to the diverse needs of various industries. The company prides itself on offering high-quality products at competitive prices, ensuring that customers receive the best value for their investment. With a commitment to customer satisfaction, Okorder.com is a reliable source for Geocomposite Drain products, providing solutions for a multitude of civil engineering challenges.

Hot Products