Tri Dimensional Drainage HDPE Network Composite Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tri Dimensional Drainage HDPE Network Composite Geotextile

Introduction:

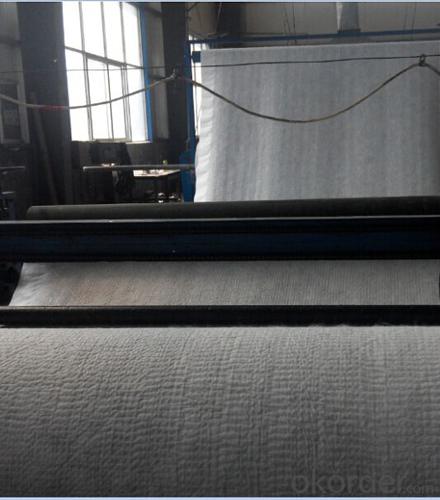

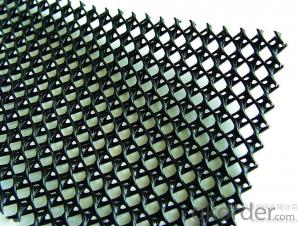

Three-dimensional composite drainage network is one three-dimension geonet composited two needle-punched non-woven geotextiles. Offering completely functions “filter-drainage-protection”. This kind of special three-dimensional structure can make it bear higher compression loading and keep certain thickness and same time offer excellent permeable performance.

Features:

1. Excellent drainage and sustain high compression loading

2. Highest tensile strength and shearing strength

3. Cut down ratio of geotextile into geonet and keep stable permeability in a long time

4. It can bear compression loading over 2000Kpa

5.Its compressive strength far exceeds general drainage geonet

Specifications and technical parameters:

Drainage network core | units | Specification | ||||

Unit weight | g/m2 | 750 | 1000 | 1300 | 1600 | |

Thickness | Mm | 5.0 | 6.0 | 7.0 | 7.6 | |

Hydraulic conductivity | m/s | kx10-4 | Kx10-4 | Kx10-4 | Kx10-4 | |

Elongation | % | 50 | 50 | 50 | 50 | |

Tensile strength (core netwaork) | kN/m | 8 | 10 | 12 | 14 | |

Geotextile | g/m2 | Heavier grades of geotextiles can be bonded to geonet on request | ||||

Usages:

In the railway, highway and other transportation infrastructure, drainage system safety and the service life

of the project and its have inseparable relationship, in which the geotextile material is an important part

of drainage system, the drainage effect of 3D composite drainage net is particularly notable. mainly

used for tunnels, municipal engineering, reservoir, revetment in drainage engineering.

FAQ

1.How about the delivery time?

Lead time since receipt of 30% T/T deposit payment: 2-3 weeks. (Samples will be prepared within 3 days.)

2. What kind of payments does jenor support?

T/T, L/C, Cash are accepted.

3. What's are the MOQ?

We can according to your condition to set the MOQ. and we can provide you samples for quality inspection before the mass production.

4. Do you charge for the samples?

Accordeing to our company policy, the samples are free, we only charge the freight fee.

5. Can you produce according to customers' design?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: Are earthwork products suitable for use in mining applications?

- Yes, earthwork products are suitable for use in mining applications. These products, such as geotextiles, geomembranes, and geosynthetics, provide effective solutions for erosion control, slope stabilization, and environmental protection in mining operations. They are designed to withstand the harsh conditions and heavy loads associated with mining activities, making them highly suitable for use in such applications.

- Q: How are precast concrete products used in earthwork?

- Precast concrete products are commonly used in earthwork to provide stability and support in various construction projects. These products, such as retaining walls, culverts, and manholes, are pre-manufactured off-site and then transported to the construction site for installation. They serve as effective solutions for soil erosion control, water drainage, and soil reinforcement, ensuring the durability and longevity of earthwork structures.

- Q: Can geocells be used for load support in pavements?

- Yes, geocells can be used for load support in pavements. Geocells are three-dimensional honeycomb-like structures made from high-density polyethylene (HDPE). They are filled with compacted soil or aggregate and placed under pavements to increase their load-bearing capacity. The confinement provided by geocells helps distribute the load evenly, reducing vertical and horizontal movement of materials and improving the overall stability and performance of the pavement.

- Q: What are the cost implications of using geosynthetics in earthwork projects?

- The cost implications of using geosynthetics in earthwork projects can vary depending on the specific project requirements, but generally, geosynthetics can help reduce construction costs in several ways. Firstly, geosynthetics such as geotextiles and geogrids can serve as effective soil reinforcement materials, reducing the need for traditional reinforcement methods like steel or concrete, which can be more expensive. Additionally, geosynthetics can enhance the stability and performance of soil structures, allowing for the use of less expensive fill materials. They can also improve drainage and filtration, reducing the need for costly drainage systems. Overall, while there may be an initial cost associated with incorporating geosynthetics, their long-term benefits and potential cost savings make them a cost-effective choice for earthwork projects.

- Q: What are the cost implications of using earthwork products?

- The cost implications of using earthwork products can vary depending on factors such as the specific product used, the quantity required, and the project's scale and complexity. Generally, earthwork products like soil, gravel, and fill materials tend to be more cost-effective compared to other construction materials. They are often readily available and can be sourced locally, reducing transportation costs. Additionally, earthwork products can be recycled or repurposed, further reducing expenses. However, there may be additional costs involved in excavation, grading, and compaction processes to prepare the site for using these products. Overall, using earthwork products can offer cost advantages but should be carefully assessed in relation to the project's specific requirements.

- Q: What are the different thickness options available in earthwork products?

- The different thickness options available in earthwork products vary depending on the specific product and its intended use. Common thickness options range from thin layers, such as geotextiles and erosion control blankets, which can be a few millimeters thick, to thicker options like geogrids and geomembranes that can be several millimeters to centimeters thick. Additionally, some earthwork products may offer different thickness options within their product line to cater to different project requirements and soil conditions.

- Q: Can earthwork products be used in mining and quarrying operations?

- Yes, earthwork products can be used in mining and quarrying operations. These products, such as geotextiles, geomembranes, and geogrids, can provide various benefits including soil stabilization, erosion control, and water drainage management. They are commonly used in mining and quarrying to reinforce slopes, control sediment runoff, and improve overall safety and efficiency of the operations.

- Q: What are the advantages of using geosynthetic materials in road shoulder construction?

- There are several advantages to using geosynthetic materials in road shoulder construction. First, geosynthetics such as geotextiles and geogrids provide excellent reinforcement and stabilization to the road shoulder, preventing erosion and maintaining its structural integrity. This helps to extend the lifespan of the road and reduce maintenance costs over time. Additionally, geosynthetics can improve the load-bearing capacity of the road shoulder, allowing it to withstand heavy traffic and vehicle loads more effectively. Moreover, these materials can enhance drainage and filtration, reducing the risk of water accumulation and improving overall road safety. Overall, the use of geosynthetic materials in road shoulder construction offers improved performance, durability, and cost-effectiveness compared to traditional construction methods.

- Q: How are geosynthetic materials used in railway tunnel construction?

- Geosynthetic materials are used in railway tunnel construction to enhance the stability and durability of the tunnel structure. These materials, such as geotextiles, geogrids, and geomembranes, are installed to provide reinforcement, drainage, and erosion control. They help in preventing soil erosion, stabilizing slopes, and improving the overall safety and performance of the tunnel.

- Q: What are the advantages of using geosynthetic materials in road subgrade stabilization?

- Some advantages of using geosynthetic materials in road subgrade stabilization include improved load-bearing capacity, reduced vertical settlement, increased durability, and enhanced drainage. These materials provide reinforcement and prevent the subgrade from weakening or undergoing excessive deformation, resulting in a longer lifespan for the road. Additionally, geosynthetics can help control moisture content, reducing the risk of water-related damage and allowing for better overall performance in various weather conditions.

Send your message to us

Tri Dimensional Drainage HDPE Network Composite Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords