Cow Carpet Geotextile Geocomposite Drain for Road, Railway, Highway, and Tunnel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000rolls m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geocomposite Drain for Road Railway Highway Tunnel

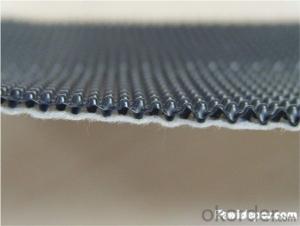

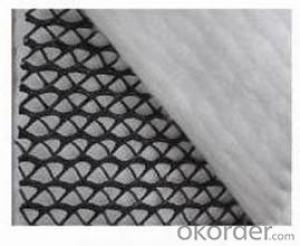

Geocomposite drain is made of fiber extruded from thermoplastic synthetic resin. It is a tri-dimen-sional material with many holes. There is a geotextile layer outside the geocomposite drain, whose main function is to sieve sand and clay so as to avoid blockage. This product has four shapes, but mmany types, including rectangular with many holes, round shape with many holes, round shape but hollow ones.

Specification of Geocomposite Drain for Road Railway Highway Tunnel

Circular shape size D50, D70, D80, Rectangle 70X30, 120X35, 300X35, 400X35.

Property of Geocomposite Drain for Road Railway Highway Tunnel

High pressure resistance, high opening rate in surface, excellent in collecting and draining water, permanent lifetime, easy for construction, good flexibility and adaptable to the earth distortion.

Application of Geocomposite Drain for Road Railway Highway Tunnel

Drainage for tunnel, roadbed and road shoulder of highway, railway, soft bed disposal, remaining wall filtration, underground building d rainage and anti-tidal air, also water collecting and draining in green field, roof garden, sewage disposal, garbage bu rying field and other works.

- Q: Is the current tunnel construction, modular waterproof board (geotextile) is available?

- We use the soil is a geotech cloth waterproof board

- Q: Are geotextiles suitable for use in underground drainage systems?

- Yes, geotextiles are suitable for use in underground drainage systems. Geotextiles are permeable fabrics that can be used to separate, filter, reinforce, and drain soil in a drainage system. They help prevent the clogging of pipes and provide additional stability and longevity to the overall system.

- Q: In ANSYS, geotextile what unit to simulate it?

- The use of shell units is relatively more reasonable.

- Q: What are the different geotextile installation techniques for roadways?

- There are several different geotextile installation techniques for roadways, including the overlay method, the trench method, and the sandwich method. - The overlay method involves placing the geotextile directly on top of the existing soil or subgrade before adding the new road material, such as asphalt or concrete. This technique helps to separate the soil layers and prevent the mixing of materials, providing stability and reducing the risk of road failure. - The trench method involves excavating a trench along the road alignment and placing the geotextile in the trench before backfilling it with soil or aggregate. This technique is commonly used for drainage applications, as the geotextile acts as a filter to prevent fine particles from clogging the drainage system, while allowing water to flow through. - The sandwich method is a combination of the overlay and trench methods. It involves placing a layer of geotextile between the existing soil and the new road material, as well as placing another layer of geotextile on top of the new road material. This technique provides additional reinforcement and separation, enhancing the overall performance and durability of the roadway. Overall, the choice of geotextile installation technique depends on the specific requirements and conditions of the road project, such as soil type, traffic load, and drainage needs.

- Q: How do geotextiles prevent soil erosion?

- Geotextiles prevent soil erosion by acting as a barrier that stabilizes the soil and enhances its strength. They are installed in the soil to prevent the movement of soil particles caused by water or wind. The geotextiles allow water to pass through while retaining the soil, thus reducing the velocity of water flow and preventing soil erosion.

- Q: Can geotextiles be used for reinforcement of slope toe protection systems?

- Yes, geotextiles can be used for the reinforcement of slope toe protection systems. Geotextiles are commonly used in slope stabilization applications to enhance soil strength, increase resistance to erosion, and provide long-term stability to the slope. They can be installed at the toe of the slope to prevent soil erosion, improve drainage, and provide additional support to the slope.

- Q: Can geotextiles be used in mining operations?

- Yes, geotextiles can be used in mining operations. Geotextiles are commonly used in mining for various applications including erosion control, soil stabilization, drainage, and separation of different materials. They can help improve the overall efficiency, sustainability, and safety of mining operations.

- Q: Can geotextiles be used in waste storage facility applications?

- Yes, geotextiles can be used in waste storage facility applications. Geotextiles can provide several benefits in waste storage facilities, such as erosion control, filtration, and separation of different layers of waste materials. They can also help to improve the stability and performance of waste storage structures by reinforcing the soil and preventing the migration of fine particles.

- Q: Can geotextiles be used in the construction of agricultural ponds?

- Yes, geotextiles can be used in the construction of agricultural ponds. Geotextiles can be employed as a barrier or liner in the pond to prevent seepage, erosion, and contamination. They help in stabilizing the soil and provide reinforcement, ensuring the longevity and durability of the agricultural pond.

- Q: National standard geotextile and non - standard how to distinguish

- Detection data are different. Appearance quality is also more obvious.

Send your message to us

Cow Carpet Geotextile Geocomposite Drain for Road, Railway, Highway, and Tunnel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000rolls m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords