Plastic Drain Cell Drainage Board for Roof Garden

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

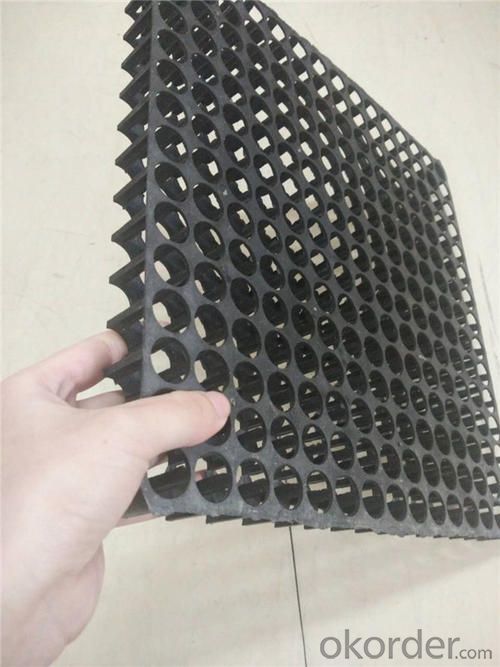

Plastic Drain Cell Drainage Board for Roof Garden

1. Introduction

Drainage cell is the lightweight three dimensional geocomposite with flat back which is pressed against an underground structure used for subsurface water management method.

Our drainage cell is lightweight, easy to use and cost effective when compared to traditional drainage methods, and it is the most advanced and versatile geo-composite product suitable for all your horizontal and vertical drainage applications such as roof garden drainage, landscape, terraces and patios under pavers, subterranean building protection, etc.

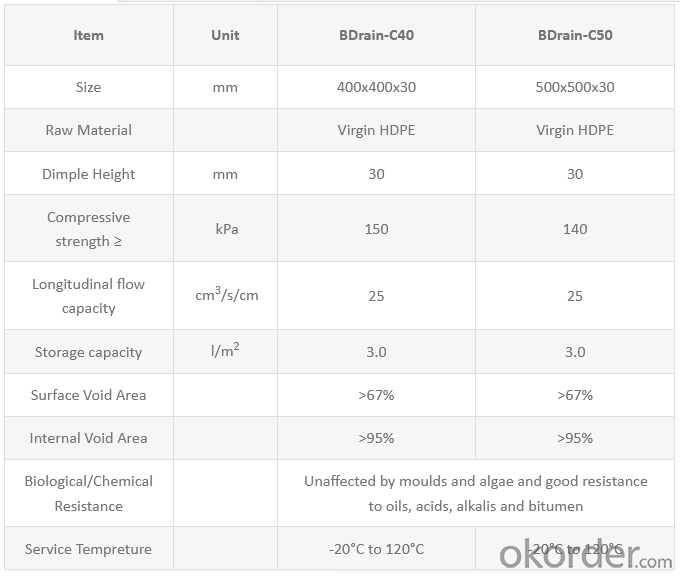

2.Specification

3. Features

1) High Compressive strength

2) Eco-friendly, waterproof polypropylene material

3) Lightweight and easily transportable

4) Thermal regulation

5) Low cost

6) Quick and easy to install

4.Applications

1) roof gardens,

2) podium landscaping,

3) retaining walls,

4) golf course,

5) sports fields,

6) bridge abutments,

7) underground car parks,

8) basements,

9) under drains for slabs/ foundations / subsurface drainage for permeable driveways

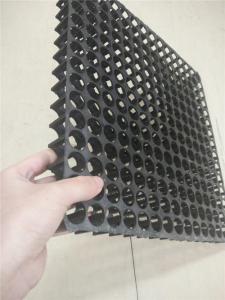

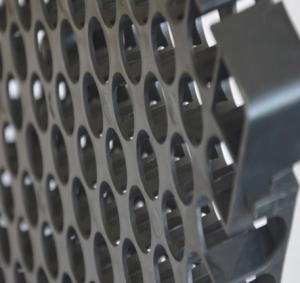

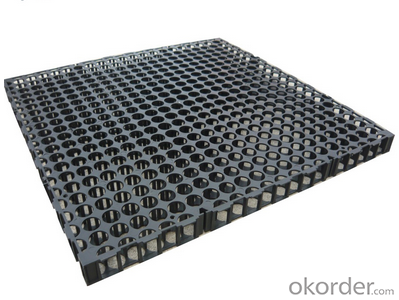

5. Pictures

6. FAQ

Q1:Are you a factory or trading company?We are a factory.

Q2:How is the quality of your products compared with other supplier?

Our price is reasonable and worty quality.

Q3:Do you have quality warranty ?

Yes,we have quality warranty under normalconditions,pls contact us for details.

Q4:How do you make our business long-team and good relationship?

We keep good quality andcompetitive price to ensure our customers benefit.

- Q: Why the ancient Chinese architecture to civil materials, while the use of stone in Europe it?

- Different ethnic, yellow constitution is relatively weak, and like warm, will use the structure! So much more wood; Western people physically strong, and advocating power, and stone can give people strong and more majestic feeling!

- Q: Are those issues focused?

- Key knowledge Abstract polymer building materials, asphalt and asphalt mixture, building functional materials, etc.

- Q: How do erosion control blankets help in slope re-vegetation in earthwork projects?

- Erosion control blankets help in slope re-vegetation in earthwork projects by providing a protective layer over the soil. These blankets are typically made of biodegradable materials, such as straw or coconut fibers, and are placed on the slope to prevent erosion caused by wind, rain, and water flow. They help retain moisture, prevent soil from being washed away, and promote the growth of vegetation by creating an ideal environment for seed germination. Additionally, erosion control blankets also offer protection against weed growth and regulate soil temperature, ultimately aiding in the successful establishment of vegetation on slopes.

- Q: How do erosion control blankets help in preventing soil erosion?

- Erosion control blankets, also known as erosion control mats, play a crucial role in preventing soil erosion. These blankets are made of biodegradable materials like straw, coconut fiber, or jute, and are placed over the soil surface. They provide immediate protection by absorbing the impact of raindrops and reducing surface runoff. Additionally, erosion control blankets help to retain moisture, promote seed germination, and stabilize the soil by preventing wind and water erosion. The blanket's fibers interlock, creating a protective barrier that prevents soil particles from being washed away. Overall, erosion control blankets act as a temporary but effective solution to prevent soil erosion until vegetation establishes itself and provides long-term protection.

- Q: What are the different surface patterns available in earthwork products?

- There are several different surface patterns available in earthwork products, including smooth, textured, stamped, and exposed aggregate finishes.

- Q: What are the benefits of using corrugated metal pipes?

- There are several benefits to using corrugated metal pipes. Firstly, they are very durable and can withstand extreme weather conditions and heavy loads, making them ideal for drainage systems and underground infrastructure. They are also resistant to rust and corrosion, ensuring a longer lifespan compared to other materials. Additionally, corrugated metal pipes are lightweight and easy to transport and install, saving both time and money. Their smooth interior surface allows for efficient flow of water or other materials, reducing the risk of clogging. Overall, corrugated metal pipes provide reliable and cost-effective solutions for various construction and infrastructure projects.

- Q: The relationship between material development and civil engineering development

- The emergence and development of new materials to promote the human society and history, civilization, progress. Material is the material basis of human production and life, is the direct driving force of social development. The development of materials and its application is an important milestone in human civilization and social progress

- Q: What are the benefits of using geosynthetic panels in slope stabilization?

- The use of geosynthetic panels in slope stabilization offers several benefits. Firstly, these panels provide an effective barrier against erosion, preventing soil movement and reducing the risk of landslides. Secondly, they enhance the stability of slopes by distributing the loads evenly, thereby minimizing the potential for slope failure. Additionally, geosynthetic panels are quick and easy to install, saving time and labor costs. They are also cost-effective compared to traditional methods of slope stabilization. Lastly, these panels are durable and resistant to environmental conditions, ensuring long-term effectiveness in slope stabilization projects.

- Q: How do earthwork products contribute to road embankment construction?

- Earthwork products such as soil, gravel, and rocks play a crucial role in road embankment construction. These materials are used to build up the foundation and support the road structure, providing stability and strength to the embankment. By carefully selecting and compacting earthwork products, engineers can ensure proper drainage, prevent erosion, and create a safe and durable road infrastructure.

- Q: What are the benefits of using geonets in land reclamation projects?

- Geonets offer several benefits in land reclamation projects, including improved soil stability, enhanced drainage, and increased erosion resistance. They provide a strong reinforcement layer, preventing soil movement and reducing the risk of slope failure. Their high permeability promotes efficient water drainage, preventing waterlogging and allowing for proper soil aeration. Geonets also help control erosion by distributing water evenly and reducing the impact of rainfall on the soil surface. Overall, the use of geonets in land reclamation projects can significantly enhance the long-term stability and productivity of reclaimed land.

Send your message to us

Plastic Drain Cell Drainage Board for Roof Garden

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords