Geocomposite Geosynthetic Clay Liner-GCL

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

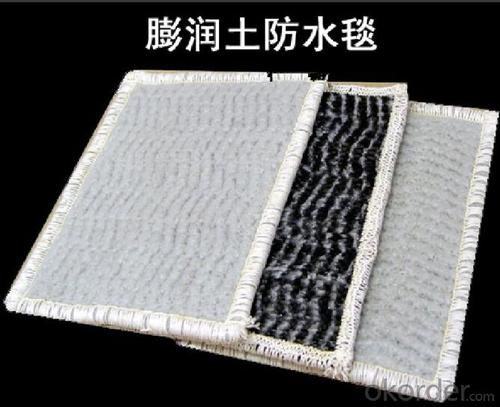

Geocomposite Geosynthetic Clay Liner

Introduction of GCL:

Geosynthetic Clay Liner is manufactured by three levels, including two levels of geotextile whose functions are protecting and strengthen to ensure shearing strength and tensile strength, inner content is Sodium bentonite clay. It is manufactured by nature layer silicate inorganic materials and has high expansibility and high water-absorbing capacity, when soak with low permeable capability, whose the main function is anti-seepage.

Features of GCL:

A:Form high density diaphragm under hydraulic pressure, the water permeable capability equals to 100 times density degree of 30cm clay when the thickness of GCL is 3mm. It has very good self water-retention property.

B:GCL is nature inorganic material, it won't aging or corrode even after long-time or surrounding changed, so it has permanent water proofing capability.

C:GCL is nature inorganic material, which is non-poisonous and harmless to human body, so it is environment protection material.

Application Filed of GCL:

Water storage, miniature reservoir, dam of reservoir, acequia,fish pond

Roof garden, basement etc.

Subway, railway, expressway, light industry, oil and metallurgy and other industry

Maintenance, repair and reinforcement of earth works

Environmental reform, garbage landfill, artificial lake or other landscape

Test Item | Test | Criteria |

Expansion coefficient | ASTM D 5890 | ≥24ml/2g |

Fluid loss | ASTM D 5891 | ≤18ml |

Bentonite clay weight of unit space | ASTM D 5993 | ≥4.8kg/sqm |

Tensile strength | ASTM D 4632 | ≥400N |

Peel strength | ASTM D 4632 | ≥65N |

Indicating flow | ASTM D 5887 | ≤1×10-8m3/sqm/sec |

Permeability | ASTM D 5887 | ≤5×10-275px/sec |

Tensile strength after soak | ASTM D 5321 | ≥24KPa typical |

FAQ:

How many quantity for one 20'' container?

About 5,000m2, 16rolls

What's your delivery time?

About 15-20days against deposit received

. What's your package?

Per roll with two pieces woven bag

- Q: Can geocells be used for erosion control on slopes?

- Yes, geocells can be used for erosion control on slopes. Geocells are three-dimensional honeycomb-like structures made of interconnected cells that can be filled with soil or other materials. When used on slopes, they provide stability and prevent soil erosion by confining the materials inside the cells and reinforcing the slope. The cells also promote vegetation growth, which further aids in erosion control. Overall, geocells are an effective solution for erosion control on slopes.

- Q: What are the different thicknesses available for earthwork products?

- The different thicknesses available for earthwork products vary depending on the specific product and its intended use. It can range from thin geotextiles or erosion control mats with thicknesses of a few millimeters to thicker geomembranes or geosynthetic clay liners with thicknesses of several millimeters or centimeters.

- Q: What are the different applications of geosynthetic clay liners?

- Geosynthetic clay liners (GCLs) have various applications in different industries. They are commonly used in landfill liners to provide a barrier against the migration of contaminants into the surrounding soil and groundwater. GCLs are also utilized in the construction of artificial ponds, canals, and reservoirs to prevent water seepage. Additionally, GCLs find application in the mining industry as part of the containment systems for tailings ponds, ensuring the safe storage of mining waste.

- Q: Civil engineering materials, what kind of

- According to the use of functional classification According to the civil engineering materials in the building parts or the use of performance, can be divided into building structural materials, wall materials, building functional materials three categories

- Q: What are the different types of geocell materials available?

- There are several types of geocell materials available, including high-density polyethylene (HDPE), polypropylene (PP), and polyester. Each material has its own unique properties and strengths, making them suitable for different applications and environments.

- Q: Can earthwork products be used for creating outdoor art installations?

- Yes, earthwork products can certainly be used for creating outdoor art installations. Earthwork materials such as soil, rocks, and natural elements can be sculpted, arranged, or manipulated to create unique and visually captivating outdoor art installations. These installations can range from land art and environmental sculptures to temporary installations and public art projects. Earthwork products offer artists a versatile and sustainable medium to express their creativity in outdoor spaces.

- Q: What are the different types of geotextile bags available for erosion control?

- There are several different types of geotextile bags available for erosion control, including sandbags, silt bags, and sediment bags. Each type of bag is designed to address specific erosion concerns and has unique characteristics and uses. Sandbags are commonly used to build temporary barriers and divert water flow, while silt bags are used to trap sediment and prevent it from entering waterways. Sediment bags are typically used in construction sites to contain and filter sediment-laden water. Overall, these geotextile bags play a crucial role in preventing erosion and protecting the environment.

- Q: How do earthwork products contribute to road embankment construction?

- Earthwork products such as soil, gravel, and rocks play a crucial role in road embankment construction. These materials are used to build up the foundation and support the road structure, providing stability and strength to the embankment. By carefully selecting and compacting earthwork products, engineers can ensure proper drainage, prevent erosion, and create a safe and durable road infrastructure.

- Q: What is the purpose of using geocomposites in subsurface drainage systems?

- The purpose of using geocomposites in subsurface drainage systems is to enhance the efficiency and longevity of the drainage system. Geocomposites are engineered materials that combine geotextiles with other components like drainage cores or geonets. These materials help to improve filtration, water flow, and soil stabilization in drainage systems. They provide a barrier against soil clogging, prevent the intrusion of fines, and facilitate the collection and removal of excess water from the subsurface. Ultimately, geocomposites help to prevent waterlogging, soil erosion, and maintain the overall stability and functionality of the subsurface drainage system.

- Q: Are earthwork products resistant to impact and vibration?

- Yes, earthwork products are generally designed to be resistant to impact and vibration. They are made from durable materials such as concrete or compacted soil, which can withstand external forces and vibrations. Additionally, certain construction techniques and reinforcement methods can further enhance their resistance to impact and vibration, making them suitable for various applications in civil engineering and infrastructure projects.

Send your message to us

Geocomposite Geosynthetic Clay Liner-GCL

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords