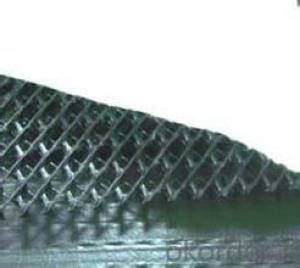

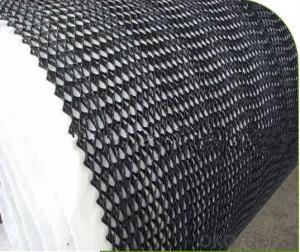

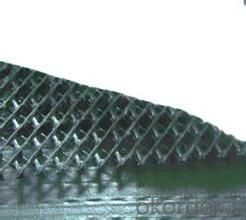

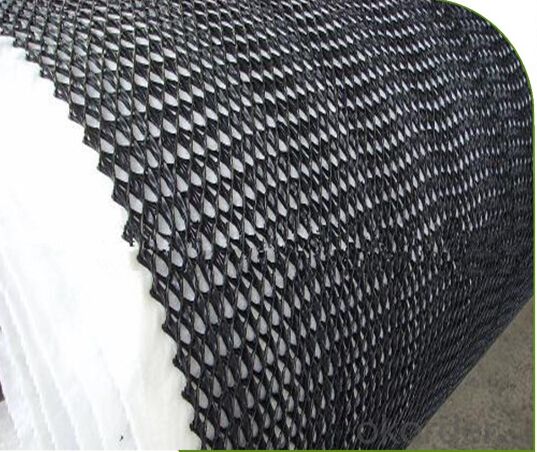

Tri HDPE Geocomposite Drainage for Slope Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tri HDPE Geocomposite Drainage for Slope Protection

Description :

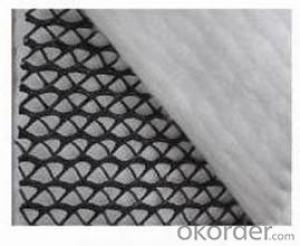

for drainage is made of a unique trmension geonet adhibited geotextile on both sides.it has the property of geotextile(filtration function ) and geonet (drainage and protection ) and provide a function system"filtration-drainage-protection".the core of net with its unique tr-dimension structure can bear higher compressing load in construction and remain the certain thickness,

provide good water conductivity.

This structure provides for high flow rates for the life of a drainage structure, not just for few hours. Therefore TENAX TENDRAIN are triplanar geocomposites engineered for long term drainage in waste containment application characterized by the following features:

Ability of the drainage structure to maintain high long term in-plane flow;

Ability of the drainage structure to withstand long term compressive loads;

Ability of the drainage structure to provide adequate shear stability.

Application:

1) Landfill drainage;

2) roadbed and road drainage;

3) railway drainage;

4) tunnel drainage,

5) underground structure drainage,

6) the retaining back wall drainage;

7) gardens and sports ground drainage

Features:

1)Excellent drainage function, can bear long time hige press load

2)High tensile and shear strength

3Reduce the rate geotextile embedding into the core of geonet, can protect long time stable water conductivity

4)Tri-dimension composite geonet for drainage can bear more than 2000kpa compression load

5)Its anti-compression capacity is much larger than common geonet for drainage

6) Certificate :ISO14001:2004, ISO9001:2008

Specifications and technical parameters:

Drainage network core | units | Specification | ||||

Unit weight | g/m2 | 750 | 1000 | 1300 | 1600 | |

Thickness | Mm | 5.0 | 6.0 | 7.0 | 7.6 | |

Hydraulic conductivity | m/s | kx10-4 | Kx10-4 | Kx10-4 | Kx10-4 | |

Elongation | % | 50 | 50 | 50 | 50 | |

Tensile strength (core netwaork) | kN/m | 8 | 10 | 12 | 14 | |

Geotextile | g/m2 | Heavier grades of geotextiles can be bonded to geonet on request | ||||

Usages:

In the railway, highway and other transportation infrastructure, drainage system safety and the service life

of the project and its have inseparable relationship, in which the geotextile material is an important part

of drainage system, the drainage effect of 3D composite drainage net is particularly notable. mainly

used for tunnels, municipal engineering, reservoir, revetment in drainage engineering.

FAQ

Questions and Answers:

Q: Can you accept sample order?

A: Yes, we accept samples with little and reasonable charge.

Q: What is your MOQ?

Q:How about your quality?

A: Try a small order, you will have your own judgment!

- Q: How are geotubes used in beach erosion control?

- Geotubes are used in beach erosion control by acting as sand-filled containers that are placed along the shoreline to create a barrier against the erosive forces of waves and currents. These large fabric tubes are filled with sand and stacked in a strategic manner to form a protective structure. Geotubes help to stabilize the beach by trapping and retaining sand, preventing erosion and maintaining the coastal profile.

- Q: How do earthwork products contribute to erosion control on hillsides?

- Earthwork products, such as retaining walls and terracing, play a crucial role in erosion control on hillsides. These products help to stabilize the soil and prevent excessive runoff by reducing the slope gradient. By creating level surfaces or step-like structures, they help to slow down the flow of water, allowing it to infiltrate into the soil rather than causing erosion. Additionally, earthwork products can also assist in redirecting water flow and preventing it from accumulating and eroding the hillside. Overall, these products provide effective erosion control measures by promoting soil stability and regulating water runoff on hillsides.

- Q: Can earthwork products be used for creating outdoor kitchens?

- Yes, earthwork products can be used for creating outdoor kitchens. Earthwork products such as bricks, stones, and concrete can be used to build the foundation, walls, and countertops of an outdoor kitchen. These materials are durable, weather-resistant, and can provide a rustic and natural aesthetic to the outdoor kitchen design. Additionally, earthwork products can be easily incorporated with other elements like wood or stainless steel to create a functional and visually appealing outdoor cooking space.

- Q: What are the specific applications of geotextile tubes in earthwork projects?

- Geotextile tubes, also known as geotubes or geotextile containers, have various applications in earthwork projects. They are commonly used for dewatering and containment purposes, such as in shoreline protection, land reclamation, and sediment control. Geotextile tubes can effectively retain and contain sediment, sludge, or other materials while allowing water to drain out. They are also used in erosion control and slope stabilization projects, providing a barrier against soil erosion and reinforcing the stability of slopes. Additionally, geotextile tubes can be utilized for temporary or permanent structures like retaining walls or berms. Overall, their specific applications in earthwork projects contribute to improving site conditions, reducing environmental impact, and enhancing project efficiency.

- Q: Material chemistry and civil engineering that employment prospects

- To thermal and power engineering as the representative of its professional direction is divided into two categories, one is the power machinery. Including heat engines, fluid machinery, hydraulic machinery and so on. The car engine is a kind of heat engine.

- Q: What is the purpose of using geocells in flood protection applications?

- The purpose of using geocells in flood protection applications is to provide a reinforced and stable structure that can help contain and control floodwaters. Geocells act as barriers, preventing the spread of water and reducing the risk of flooding in vulnerable areas. Additionally, they help to control erosion and stabilize the soil, providing long-term protection against future flooding events.

- Q: Can earthwork products be customized or made to order?

- Yes, earthwork products can be customized or made to order.

- Q: Civil Engineering Science and Technology Examination

- To pay more attention to their school, you can go to see the school graduate network, or the school Post it, where it should be more convenient to get what you want!

- Q: Are there any specific earthwork products available for sports field construction?

- Yes, there are specific earthwork products available for sports field construction. These include materials such as topsoil, subsoil, sand, and gravel, which are used for grading, leveling, and providing proper drainage on sports fields. Additionally, specialized products like synthetic turf and rubber infill are used for artificial turf installations on sports fields.

- Q: How are geosynthetic erosion control blankets used in earthwork?

- Geosynthetic erosion control blankets are used in earthwork to prevent soil erosion and promote vegetation growth. They are placed on slopes, embankments, or disturbed areas to stabilize the soil, prevent rainfall runoff, and protect against wind erosion. These blankets provide a physical barrier that allows water to infiltrate while retaining soil particles, reducing erosion and sedimentation. Additionally, they promote the establishment of vegetation by providing a favorable environment for seed germination and root growth. Overall, geosynthetic erosion control blankets are essential in earthwork to ensure long-term stability and sustainability of the soil.

Send your message to us

Tri HDPE Geocomposite Drainage for Slope Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords