Geocomposite Geonet For Drainage with High Quality Level

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

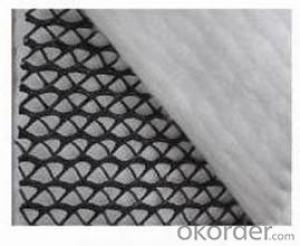

Geocomposite Geonet For Drainage

Introduction:

Geocomposite Geonet For Drainage are engineered to replace costly, conventional open graded aggregate and/or perforated- pipe subsurface drainage systems. The Geonet-geotextile Drainage Geocomposite is created by laminating a filtration geotextile on one or both sides of a Geonet. Geocomposite Drainages have reached acceptance as state-of-the-practice because they provide sufficient in-place drainage and offer reduced material cost, installation time and design complexity over conventional systems.

Specifications and technical parameters:

Item | Unit | |||||||

1200g | 1400g | 1600g | 1800g | 2000g | ||||

1 | Compound Weight of Unit Area | g/m2 | ≥1200 | ≥1400 | ≥1600 | ≥1800 | ≥2000 | |

2 | Compound Thickness | mm | ≥6.0 | ≥7.0 | ≥8.0 | ≥9.0 | ≥10.0 | |

3 | Compound Tensile Strength | KN/m | ≥16.0 | ≥16.0 | ≥16.0 | ≥16.0 | ≥16.0 | |

4 | Compound Hydraulic Conductivity | m2/s | ≥1.2×10-4 | ≥1.2×10-4 | ≥1.2×10-4 | ≥1.2×10-4 | ≥1.2×10-4 | |

5 | Net and Non-woven Geotextile Peel Strength | KN/m | ≥0.3 | ≥0.3 | ≥0.3 | ≥0.3 | ≥0.3 | |

6 | Net Thickness | mm | ≥5.0 | ≥5.0 | ≥6.0 | ≥7.0 | ≥8.0 | |

7 | Net Tensile Strength | KN/m | ≥13.0 | ≥15.0 | ≥15.0 | ≥15.0 | ≥15.0 | |

8 | Non-woven Geotextile Weight of Unit Area | g/m2 | ≥200 | ≥200 | ≥200 | ≥200 | ≥200 | |

9 | Non-woven Geotextile Permeability | cm/s | ≥0.3 | ≥0.3 | ≥0.3 | ≥0.3 | ≥0.3 | |

10 | Width | m | 2.1 | 2.1 | 2.1 | 2.1 | 2.1 | |

11 | Roll Length | m | 30 | 30 | 30 | 30 | 30 | |

Application:

1). Mainly used in the project of soft base disposal.

2). Used in the roadbed reinforcement.

3).Used in the slope fence and slope of coast protection.

4). Used in the bridge platform reinforcement.

5) used in the reinforcement of the bottom of reservoir.

6). Used in grassed car parks, overflow car parks, golf buggy paths, light aircraft taxiways, grass paths, grass car parks, emergency access routes, equestrian surface reinforcement, grass verges protection and caravan parks.

Features:

1)Excellent drainage function, can bear long time hige press load

2)High tensile and shear strength

3Reduce the rate geotextile embedding into the core of geonet, can protect long time stable water conductivity

4)Tri-dimension composite geonet for drainage can bear more than 2000kpa compression load

5)Its anti-compression capacity is much larger than common geonet for drainage

6) Certificate :ISO14001:2004, ISO9001:2008

FAQ:

1) Can you supply free samples?

Yes, our samples are free, but express fees are usually on buyer's account.

2) Can you accept third party test?

Yes, we accept totally and we also have done so many tests, like SGS, BSJ, etc.

- Q: How durable are earthwork products?

- Earthwork products, such as retaining walls and drainage systems, are designed to be highly durable and long-lasting. They are typically made from sturdy materials such as concrete, steel, or geosynthetics, which are resistant to weathering, erosion, and other environmental factors. Properly installed and maintained, earthwork products can withstand the test of time and provide reliable functionality for many years.

- Q: How do earthwork products contribute to land remediation and restoration?

- Earthwork products, such as soil, sand, and gravel, play a crucial role in land remediation and restoration. These products are used to fill and level contaminated or damaged land, creating a stable foundation for further remediation efforts. Additionally, earthwork products can be used to create berms, barriers, or containment structures that prevent the spread of pollutants and protect sensitive ecosystems. By providing the necessary materials for land regrading, erosion control, and vegetation establishment, earthwork products facilitate the rehabilitation of degraded land, ultimately restoring its functionality and ecological value.

- Q: Are earthwork products resistant to UV radiation?

- Yes, earthwork products are generally resistant to UV radiation. The materials used in earthwork products, such as geomembranes and geotextiles, are designed to withstand long-term exposure to sunlight without significant degradation or damage from UV radiation.

- Q: Can earthwork products be used for constructing outdoor fire pits?

- Yes, earthwork products can be used for constructing outdoor fire pits. Materials such as gravel, sand, and clay are commonly used in earthworks and can be utilized to create a stable and functional base for fire pits. Additionally, these materials can help with drainage and heat retention, making them suitable for outdoor fire pit construction.

- Q: How can geogrids be used in road construction projects?

- Geogrids can be used in road construction projects to enhance the stability and strength of the road base and subgrade. They are typically placed between layers of soil or aggregate to distribute load, reduce soil movement, and improve overall performance of the road. Additionally, geogrids can help control cracking, prevent rutting, and increase the lifespan of the road by reinforcing the layers and providing better load distribution.

- Q: What are the limitations of using geosynthetics in certain soil conditions?

- The limitations of using geosynthetics in certain soil conditions primarily stem from the potential for reduced effectiveness or failure of these materials. Geosynthetics, such as geotextiles, geogrids, or geomembranes, are designed to improve the performance of soils by providing reinforcement, separation, filtration, or containment. However, in certain soil conditions, their effectiveness may be compromised. One limitation is the presence of highly cohesive or clayey soils. Geosynthetics may struggle to effectively interlock with these types of soils, reducing their ability to provide reinforcement. Moreover, clayey soils can cause clogging or blinding of geotextiles, diminishing their filtration capabilities. Another limitation arises from soils with a high water content. In saturated conditions, geosynthetics can experience reduced tensile strength, leading to a decreased ability to provide reinforcement. Additionally, the presence of excessive water can cause geotextiles to float or migrate, undermining their intended function. Certain aggressive soil environments can also pose limitations. For instance, soils with high acidity or alkalinity, high salinity, or chemical contaminants may degrade or chemically react with geosynthetics, impairing their longevity and performance. In such cases, alternative materials or additional protective measures may be required. Furthermore, geosynthetics may be less effective in loose or granular soils where they can experience limited interlock or embedment. This can reduce their ability to provide reinforcement or separation, compromising project integrity. In summary, while geosynthetics offer numerous advantages in soil improvement, their performance can be limited in certain soil conditions, including highly cohesive or clayey soils, saturated conditions, aggressive soil environments, and loose or granular soils. It is crucial to consider these limitations and select appropriate geosynthetic materials and installation techniques accordingly.

- Q: How can geotextile bags be used in riverbank protection?

- Geotextile bags can be used in riverbank protection by being filled with soil or other suitable materials and then placed along the riverbank. These bags act as a barrier, preventing erosion and stabilizing the soil, thereby protecting the riverbank from further degradation. Additionally, the permeable nature of geotextile bags allows for water drainage while retaining the soil, promoting vegetation growth and aiding in the overall stability of the riverbank.

- Q: Are earthwork products suitable for use in railway track construction?

- Yes, earthwork products are suitable for use in railway track construction. These products, such as aggregates, ballast, and embankments, provide stability and support to the tracks, ensuring safe and efficient train operations. Additionally, earthwork materials are cost-effective, readily available, and can be easily sourced locally, making them a viable option for railway track construction projects.

- Q: For the civil engineering students, material mechanics need to grasp to what extent? Focus on Pretty good reference book

- Material mechanics are as important as civil professionals as the Bible to Christians. The best degree to test more than 90 points. Almost every chapter is the focus, but the bending-related chapters are the most important.

- Q: Are earthwork products suitable for commercial construction projects?

- Yes, earthwork products are suitable for commercial construction projects. Earthwork products, such as fill dirt, gravel, and rock, are commonly used in various stages of commercial construction, including site preparation, grading, and foundation construction. These materials provide stability, support, and proper drainage for commercial buildings, making them essential components of the construction process. Additionally, earthwork products can be tailored to meet specific project requirements, ensuring they are suitable for a wide range of commercial construction projects.

Send your message to us

Geocomposite Geonet For Drainage with High Quality Level

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords