Geocomposite Geosynthetic Clay Liner/GCL

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

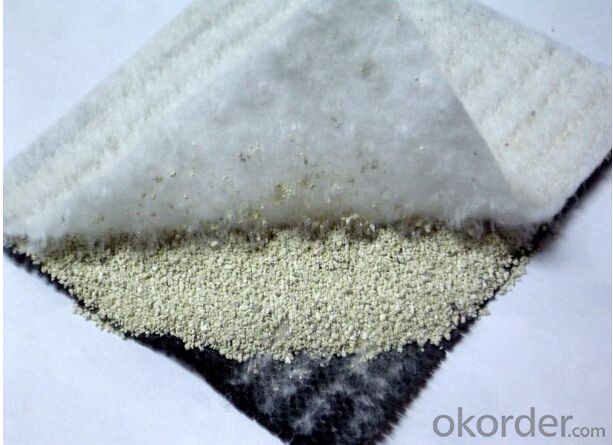

Geocomposite Geosynthetic Clay Liner/GCL

Introduction:

Mass per unit ≥ 4000g / m²

Width: 4-6 m

size: 5.8 x 30m , or customized

bentonite sandwiched between two layers of geotextile

Features:

1) Environment friendly. Liu Fangzi GCL is made of natural raw materials of sodium bentonite. Aging and corrosion never happen. It can keep its quality and then it does not cause any injuries and pollution for human and the environment. It is not only waterproof, but also has good ventilation performance. It can stick up for the exchange of the ecological environment. It is a pure natural, new, green waterproof material.

2) Permanent waterproof, excellent performance. Natural sodium bentonite has been formed for billions of years.Its waterproof properties are much longer than that of the buildings. Sodium bentonite would transform to high density septum under hydro pressure. When the thickness is 3mm, the permeability is below a×10-11/sec(a=1~9), which equals to the density of 100 times of the clay with 30 mm thickness. Water retention performance is evident.

3) Easy to use. Bentonite powder, nails and washers are enough for connection and fixation. Construction is not constrained by weather conditions and it could be taken under cold or wet conditions. Bentonite powder is spread on overlap point. When water comes, GCL would be overlapped automatically. It has been so far the only material that starts the waterproof effect by water in the world. It is not necessary to take additional examination when the construction is completed. The repair works are easy in case of waterproof defects. Among the existing waterproof materials, GCL’s construction period is the shortest and its operation is the easiest. It has an eminent effect on shortening the construction period as well as saving the cost.

4) Strong Self-Restore Capacity. The integration between waterproof material and its target enables GCL a 20~28 times swelling volume. Even if concrete structure trembles or subsides, the bentonite in GCL would restore the crack of 2mm or below on the concrete structure immediately. Even if the diameter of perforation reaches 30 mm, the restoration will be finished within 15 days completely.

Applications:

Seepage proofing, anticorrosion, leaking stoppage and reinforcement

1. Municipal engineering, underground construction of subway, buildings as well as the roof tank.

2. Environmental sanitation, solid waste landfill, sewage farm, industrial waste

3. Water conservancy, lake, river, dam and reservoir.

4. Garden and park, artificial lake and golf cause pool.

5. Petrochemical engineering, mining industry and agriculture engineering

GCL Technical Index

Item | Specification | ||||

GCL-NP | GCL-OF | GCL-AH | |||

Mass per unit g/m2 | ≥ 4000 (not less than the specified value) | ≥ 4000 (not less than the specified value) | ≥ 4000 (not less than the specified value) | ||

GCL expansion index ml/2g | ≥24 | ≥24 | ≥24 | ||

Blue absorption power g/100g | ≥ 30 | ≥ 30 | ≥ 30 | ||

Tensile Strength N/ 100mm | ≥ 600 | ≥ 700 | ≥ 600 | ||

Elongation at maximum load % | ≥ 10 | ≥ 10 | ≥ 8 | ||

Peel strength N / 100mm | Nonwoven geotextile and woven geotextile | ≥ 40 | ≥ 40 | - | |

PE geommebrane and nonwoven geotextile | - | ≥ 30 | - | ||

Permeability coefficient m/s | ≤ 5.0x10-11 | ≤ 5.0x10-12 | ≤ 1.0x10-12 | ||

Hydrostatic pressure resistant | 0.4 Mpa , 1h, no leakage | 0.6 Mpa ,1h,no leakage | 0.6Mpa ,1h, no leakage | ||

Filter loss ml | ≤ 18 | ≤ 18 | ≤ 18 | ||

Durability of bentonite ml/ 2g | ≥ 20 | ≥ 20 | |||

FAQ:

How many quantity for one 20'' container?

About 5,000m2, 16rolls

What's your delivery time?

About 15-20days against deposit received

. What's your package?

Per roll with two pieces woven bag

- Q: What are the four major mechanics in civil engineering?

- Should be theoretical mechanics, material mechanics, structural mechanics, soil mechanics

- Q: How are sediment control products used in earthwork?

- Sediment control products are used in earthwork to effectively manage and prevent erosion and sediment runoff. These products, such as sediment barriers, silt fences, and sediment basins, are strategically placed in construction sites to control the movement of sediment-laden water, ensuring the protection of nearby water bodies and minimizing environmental impacts.

- Q: How do geosynthetic products contribute to erosion control in coastal areas?

- Geosynthetic products play a crucial role in erosion control in coastal areas by providing effective solutions to stabilize and protect the shoreline. These products, such as geotextiles, geogrids, and geocells, are designed to enhance the natural resilience of coastal ecosystems while preventing land loss due to erosion. They are used in various applications like beach nourishment, dune stabilization, revetments, and breakwaters. By providing additional structural support, geosynthetics help to dissipate wave energy, reduce sediment transport, and promote sediment accretion. Overall, geosynthetic products are instrumental in maintaining the integrity of coastal areas and safeguarding them from erosion.

- Q: How do earthwork products affect the overall structural stability of a project?

- Earthwork products, such as soil, gravel, and rocks, play a crucial role in determining the overall structural stability of a project. These materials are used as foundations, backfills, and retaining structures, providing support and stability to the structures built on top of them. The quality, properties, and compaction of earthwork products directly influence the load-bearing capacity, settlement, and resistance to external forces of a project. Proper selection and compaction of these materials are essential to ensure the long-term stability and safety of the project.

- Q: What is the lifespan of geocomposite drainage systems?

- The lifespan of geocomposite drainage systems can vary depending on factors such as the quality of materials used, installation techniques, and the conditions in which they are used. However, with proper installation and maintenance, geocomposite drainage systems can have a lifespan of 25 to 50 years or more.

- Q: Can earthwork products be used for reservoir construction?

- Yes, earthwork products can be used for reservoir construction. These products, such as soil, gravel, and rocks, are commonly used in the construction of reservoirs to create embankments, line the reservoir bottom for stability, and provide erosion control.

- Q: How do erosion control blankets work?

- Erosion control blankets work by providing a protective layer on the soil surface, preventing soil erosion caused by wind, water, or other factors. These blankets are typically made of biodegradable materials that allow water and air to pass through while stabilizing the soil. The blankets promote vegetation growth by creating a favorable microclimate for seed germination and providing a physical barrier against soil erosion.

- Q: What are the different applications of geotextile bags?

- Geotextile bags have various applications, including erosion control, shoreline protection, land reclamation, riverbank stabilization, sediment containment, and dewatering during construction projects. They are also used in agriculture for soil erosion prevention and in environmental engineering for waste containment and filtration.

- Q: What are the different applications of geotextile bags in erosion control?

- Geotextile bags are commonly used in erosion control for various applications such as slope stabilization, shoreline protection, riverbank restoration, and soil erosion prevention. These bags act as barriers to filter sediment, retain soil, and dissipate water flow, effectively reducing the impact of erosion and promoting vegetation growth. They are versatile and can be utilized in different environments and terrains, making them an essential tool in erosion control projects.

- Q: Construction and sales business tax how to calculate?

- For taxpayers engaged in construction, repair, decoration works, regardless of how the other party settlement, the turnover should include the use of raw materials and other materials and power prices, including

Send your message to us

Geocomposite Geosynthetic Clay Liner/GCL

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords