HDPE Drainage Geocomposite with More Than 10Years

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HDPE Drainage Geocomposite

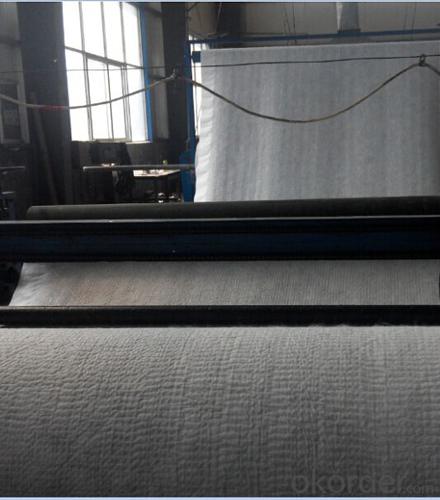

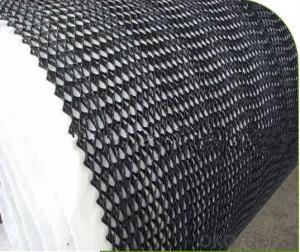

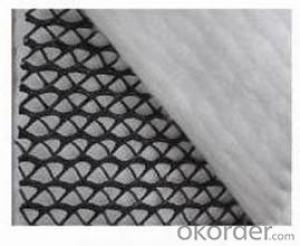

Introduction for HDPE Drainage Geocomposite

Three-dimensional composite drainage network is one three-dimension geonet composited two needle-punched non-woven geotextiles. Offering completely functions “filter-drainage-protection”. This kind of special three-dimensional structure can make it bear higher compression loading and keep certain thickness and same time offer excellent permeable performance.

Features for HDPE Drainage Geocomposite

1. Excellent drainage and sustain high compression loading

2. Highest tensile strength and shearing strength

3. Cut down ratio of geotextile into geonet and keep stable permeability in a long time

4. It can bear compression loading over 2000Kpa

5.Its compressive strength far exceeds general drainage geonet

Application for HDPE Drainage Geocomposite

Using for drainage such as refuse landfill, roadbed & road surface, railway, tunnel, underground structure, retaining wall, garden, sports ground and so on.

Technical Data for HDPE Drainage Geocomposite

Drainage network core | units | Specification | ||||

Unit weight | g/m2 | 750 | 1000 | 1300 | 1600 | |

Thickness | Mm | 5.0 | 6.0 | 7.0 | 7.6 | |

Hydraulic conductivity | m/s | kx10-4 | Kx10-4 | Kx10-4 | Kx10-4 | |

Elongation | % | 50 | 50 | 50 | 50 | |

Tensile strength (core netwaork) | kN/m | 8 | 10 | 12 | 14 | |

Geotextile | g/m2 | Heavier grades of geotextiles can be bonded to geonet on request | ||||

FAQ

1.How about the delivery time?

Lead time since receipt of 30% T/T deposit payment: 2-3 weeks. (Samples will be prepared within 3 days.)

2. What kind of payments does jenor support?

T/T, L/C, Cash are accepted.

3. What's are the MOQ?

We can according to your condition to set the MOQ. and we can provide you samples for quality inspection before the mass production.

4. Do you charge for the samples?

Accordeing to our company policy, the samples are free, we only charge the freight fee.

5. Can you produce according to customers' design?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: Can earthwork products be used for underground drainage systems?

- Yes, earthwork products can be used for underground drainage systems. These products, such as geotextiles, geogrids, and geocomposites, are commonly used in underground drainage systems to improve filtration, soil stabilization, and water flow management. They help prevent soil erosion, retain moisture, and enhance the overall performance and longevity of the drainage system.

- Q: Can earthwork products be used for constructing retaining terraces?

- Yes, earthwork products can be used for constructing retaining terraces. These products, such as soil, rocks, and geotextiles, can be used to build sturdy and durable retaining walls that hold back soil and prevent erosion on sloped terrains.

- Q: What are the key considerations when using geosynthetic materials in bridge construction?

- Some key considerations when using geosynthetic materials in bridge construction include selecting the appropriate type of geosynthetic material based on the specific project requirements, considering the durability and longevity of the material, ensuring proper installation and construction techniques, evaluating the material's ability to withstand environmental factors such as temperature changes and moisture, and conducting regular inspections and maintenance to ensure the material's performance over time. Additionally, it is important to consider the cost-effectiveness of using geosynthetics compared to traditional construction materials and methods.

- Q: How do geocells help in load transfer platforms?

- Geocells help in load transfer platforms by providing a stable and reinforced foundation. They act as a confinement system for infill materials, such as soil or aggregate, preventing lateral spreading and enhancing load distribution. The cellular structure of geocells increases the overall stiffness and load-bearing capacity of the platform, effectively transferring and distributing loads more efficiently.

- Q: What are the benefits of using geogrids in mechanically stabilized earth walls?

- Geogrids provide numerous benefits in mechanically stabilized earth walls. Firstly, they enhance the overall stability and load-bearing capacity of the wall by providing reinforcement and distributing loads more effectively. Secondly, geogrids minimize lateral earth pressure, reducing the risk of wall failure or deformation. Additionally, they offer excellent soil confinement, preventing soil erosion and enhancing long-term performance. Geogrids also facilitate faster and more cost-effective construction, as they are easy to install and require minimal maintenance. Overall, geogrids significantly improve the durability, strength, and performance of mechanically stabilized earth walls.

- Q: What is the difference between building materials and civil engineering materials?

- The contents of civil engineering materials include green building materials, basic properties of civil engineering materials, air and hard inorganic cementitious materials, cement, concrete, mortar, wall materials and roofing materials, steel and aluminum, wood, asphalt and asphalt mixture Materials, waterproof materials, insulation sound insulation sound insulation materials, building decoration materials

- Q: What are the different installation guidelines for earthwork products?

- The specific installation guidelines for earthwork products can vary depending on the type of product being used. However, some general guidelines include properly preparing the site by removing any vegetation or debris, ensuring proper drainage to prevent water accumulation, compacting the soil or base material to create a stable foundation, and carefully following the manufacturer's instructions for product installation. It is also important to consider factors such as slope stability, soil conditions, and local regulations when installing earthwork products.

- Q: What are the different types of geosynthetic drainage systems for sports fields?

- There are several types of geosynthetic drainage systems commonly used for sports fields, including geocomposite drains, geonet drains, and geospacer drains. These systems are designed to effectively manage water on the field's surface and below, preventing waterlogging and ensuring proper drainage to maintain a safe and playable surface.

- Q: How are geotextile mats used in erosion control on coastal cliffs?

- Geotextile mats are used in erosion control on coastal cliffs by being installed on the slopes to stabilize the soil and prevent erosion. These mats provide a protective layer that helps in retaining moisture, reducing surface runoff, and increasing the vegetation growth. Additionally, they help to absorb and dissipate the energy of waves and tides, minimizing the impact of water on the cliff face. Overall, geotextile mats play a crucial role in maintaining the stability and protection of coastal cliffs against erosion.

- Q: Can earthwork products be used in slope reinforcement?

- Yes, earthwork products can be used in slope reinforcement. These products, such as geotextiles, geogrids, and erosion control blankets, are specifically designed to stabilize and reinforce slopes. They help to prevent soil erosion, improve slope stability, and provide long-term support to the slopes.

Send your message to us

HDPE Drainage Geocomposite with More Than 10Years

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords