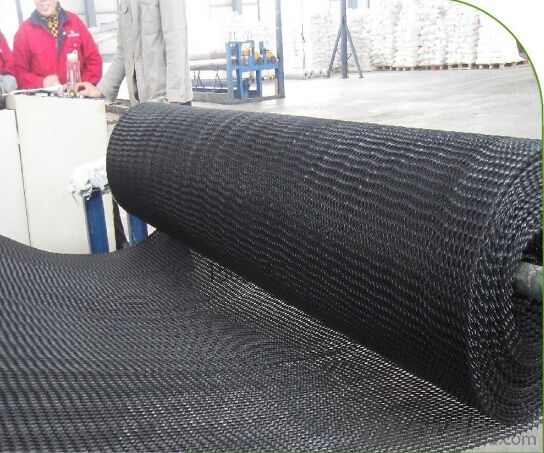

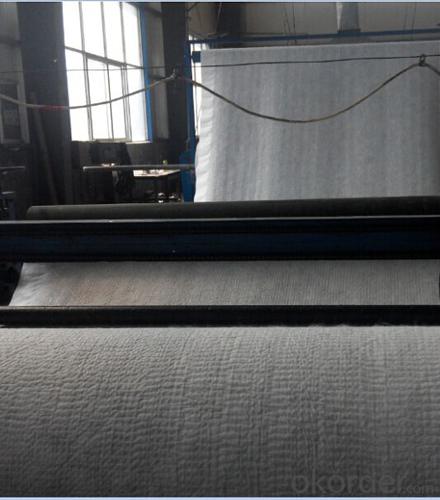

Tri-dimension Composite Geonet for Drainage Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HDPE Geocomposite Geonet for Drainage Use

Description :

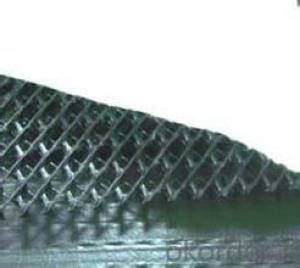

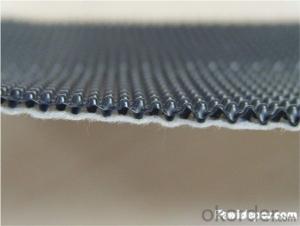

for drainage is made of a unique trmension geonet adhibited geotextile on both sides.it has the property of geotextile(filtration function ) and geonet (drainage and protection ) and provide a function system"filtration-drainage-protection".the core of net with its unique tr-dimension structure can bear higher compressing load in construction and remain the certain thickness,

provide good water conductivity.

Application:

1) Landfill drainage;

2) roadbed and road drainage;

3) railway drainage;

4) tunnel drainage,

5) underground structure drainage,

6) the retaining back wall drainage;

7) gardens and sports ground drainage

Features:

1)Excellent drainage function, can bear long time hige press load

2)High tensile and shear strength

3Reduce the rate geotextile embedding into the core of geonet, can protect long time stable water conductivity

4)Tri-dimension composite geonet for drainage can bear more than 2000kpa compression load

5)Its anti-compression capacity is much larger than common geonet for drainage

6) Certificate :ISO14001:2004, ISO9001:2008

Specifications and technical parameters:

Item | Unit | |||||||

1200g | 1400g | 1600g | 1800g | 2000g | ||||

1 | Compound Weight of Unit Area | g/m2 | ≥1200 | ≥1400 | ≥1600 | ≥1800 | ≥2000 | |

2 | Compound Thickness | mm | ≥6.0 | ≥7.0 | ≥8.0 | ≥9.0 | ≥10.0 | |

3 | Compound Tensile Strength | KN/m | ≥16.0 | ≥16.0 | ≥16.0 | ≥16.0 | ≥16.0 | |

4 | Compound Hydraulic Conductivity | m2/s | ≥1.2×10-4 | ≥1.2×10-4 | ≥1.2×10-4 | ≥1.2×10-4 | ≥1.2×10-4 | |

5 | Net and Non-woven Geotextile Peel Strength | KN/m | ≥0.3 | ≥0.3 | ≥0.3 | ≥0.3 | ≥0.3 | |

6 | Net Thickness | mm | ≥5.0 | ≥5.0 | ≥6.0 | ≥7.0 | ≥8.0 | |

7 | Net Tensile Strength | KN/m | ≥13.0 | ≥15.0 | ≥15.0 | ≥15.0 | ≥15.0 | |

8 | Non-woven Geotextile Weight of Unit Area | g/m2 | ≥200 | ≥200 | ≥200 | ≥200 | ≥200 | |

9 | Non-woven Geotextile Permeability | cm/s | ≥0.3 | ≥0.3 | ≥0.3 | ≥0.3 | ≥0.3 | |

10 | Width | m | 2.1 | 2.1 | 2.1 | 2.1 | 2.1 | |

11 | Roll Length | m | 30 | 30 | 30 | 30 | 30 | |

FAQ

Questions and Answers:

Q: Can you accept sample order?

A: Yes, we accept samples with little and reasonable charge.

Q: What is your MOQ?

Q:How about your quality?

A: Try a small order, you will have your own judgment!

Q: how about your delivery time?

A:Our delivery time is within 15days against deposit received

Q: can you provide other geosynthetics?

Yes, we can supply more than 30kinds of geosynthetics, like geogrid, geotextile, geomembrane, geobag, geocomposite, etc.

- Q: What are the seismic performance properties of earthwork products?

- The seismic performance properties of earthwork products refer to their ability to withstand and resist the effects of seismic activity, such as earthquakes. These properties include factors such as the material's strength, stiffness, durability, and resistance to shaking and ground movement. Earthwork products with good seismic performance properties are designed and engineered to minimize damage and ensure the safety and stability of structures during seismic events.

- Q: How do earthwork products contribute to LEED certification?

- Earthwork products can contribute to LEED (Leadership in Energy and Environmental Design) certification by meeting specific criteria related to sustainability and environmental impact. These products, such as recycled aggregates or locally sourced materials, can help achieve points in various LEED categories, including Materials and Resources, Regional Priority, and Innovation in Design. By using earthwork products that are environmentally friendly and meet LEED requirements, construction projects can enhance their overall sustainability performance and work towards obtaining LEED certification.

- Q: How do earthwork products compare to traditional construction materials in terms of cost?

- Earthwork products, such as soil, gravel, and rocks, tend to be more cost-effective compared to traditional construction materials. This is primarily because earthwork materials are often readily available on-site or can be easily sourced locally, reducing transportation costs. Additionally, earthwork products can be recycled or reused, further minimizing expenses. On the other hand, traditional construction materials like concrete, steel, and lumber typically require more resources, energy, and manufacturing processes, making them relatively more expensive. However, it is important to note that the specific cost comparison may vary depending on factors such as project location, scale, and availability of materials.

- Q: What are the different installation techniques for earthwork products?

- There are several different installation techniques for earthwork products, depending on the specific product and the intended use. Some common techniques include excavation and grading, compaction, backfilling, and erosion control. Excavation and grading involve removing excess soil and shaping the land to the desired contours. Compaction involves using heavy machinery to compress the soil, making it more stable and able to support structures. Backfilling is the process of filling in excavated areas with soil or other materials to provide support and stability. Erosion control techniques, such as installing erosion control blankets or retaining walls, are used to prevent soil erosion and maintain the integrity of the earthwork.

- Q: How do earthwork products contribute to water quality improvement?

- Earthwork products contribute to water quality improvement in several ways. Firstly, they can be used to create natural filtration systems, such as wetlands or bioswales, which help remove pollutants and sediment from stormwater runoff before it reaches water bodies. Secondly, earthwork products, such as retaining walls or berms, can be strategically placed to prevent erosion and soil runoff, thereby reducing the amount of sediment and nutrients entering waterways. Lastly, earthwork products can be used to create rain gardens or infiltration basins, which promote the infiltration of stormwater into the ground, allowing for natural filtering and recharge of groundwater resources. Overall, earthwork products play a vital role in managing stormwater and protecting water quality.

- Q: Can earthwork products be used in slope stabilization projects?

- Yes, earthwork products can be used in slope stabilization projects. These products, such as geotextiles, geogrids, and geomats, are designed to reinforce and stabilize slopes by improving soil stability, preventing erosion, and enhancing drainage. They are commonly used in various slope stabilization applications, including embankments, retaining walls, and landslide mitigation projects.

- Q: Can earthwork products be used for creating outdoor shower areas?

- Yes, earthwork products can be used for creating outdoor shower areas. Earthwork products such as natural stones, gravel, and sand can be used for constructing the base and flooring of the shower area. Additionally, earthwork materials like rocks and boulders can be used to create decorative features or privacy walls around the shower area.

- Q: How do earthwork products contribute to slope stabilization on highways?

- Earthwork products, such as geotextiles, geogrids, and erosion control blankets, play a crucial role in slope stabilization on highways. These products are designed to reinforce and stabilize the soil, preventing erosion and slippage on slopes. Geotextiles act as a separation layer, preventing the migration of fine particles while allowing water to drain through. Geogrids provide tensile strength to the soil, increasing its stability and preventing movement. Erosion control blankets offer protection against surface erosion by promoting vegetation growth and reducing water flow velocity. Overall, these earthwork products enhance the structural integrity of slopes, ensuring the safety and longevity of highways.

- Q: Can earthwork products be used for creating outdoor seating in parks?

- Yes, earthwork products such as soil, gravel, or rocks can be utilized for creating outdoor seating in parks. These materials can be shaped and arranged to build benches, seating walls, or terraces, providing functional and natural seating options for park visitors.

- Q: Are there any specific earthwork products available for sports field construction?

- Yes, there are specific earthwork products available for sports field construction. These may include materials like topsoil, sand, gravel, and drainage systems that are designed to meet the specific needs of sports fields, ensuring proper drainage, stability, and optimal playing conditions.

Send your message to us

Tri-dimension Composite Geonet for Drainage Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords