Composite Dimple Geomembrane for Civil Engineering Project Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Composite Dimple Geomembrane Description:

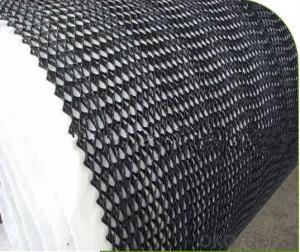

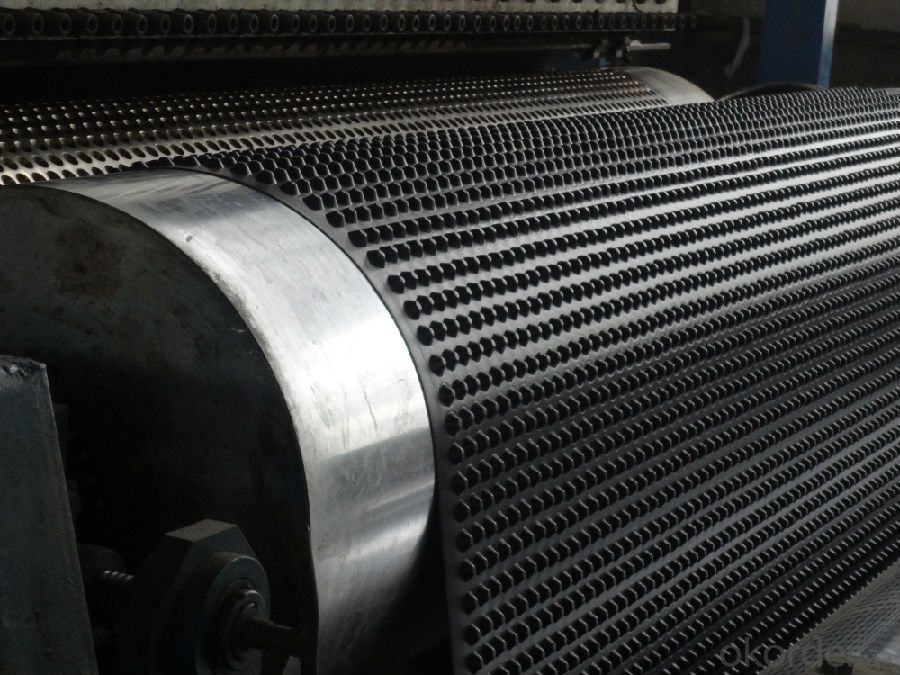

Composite dimple geomembrane is made from high density polyethylene resins and produced by extruding plastic sheet into dimple shape. The dimples can be in cylinder and semi coneshape. Theses dimples, in spatial structure with certain height, can resist long term high pressure without deformation. On the top of dimples, it is filtration geotextile to make sure the drainage channel runing well without any block by any articles.

Composite Dimple Geomembrane Specification:

Material of dimple sheet: HDPE, EVA

Thickness of dimple sheet:0.8-2.0mm

Dimple height:8-30mm

Material of nonwoven geotextile: PP, PET

Weight of nonwoven geotextile: ≥100g/m2

Width:2m-3m

Length: as customer’s request

Color: black, white

Composite Dimple Geomembrane Technical Data Sheet:

No. | Item | Value | |||||

1 | Model | H10-1.0 | H20-1.0 | H10-1.5 | H20-1.5 | H10-2.0 | H20-2.0 |

2 | Tensile strength(N/125px) | 400 | 400 | 500 | 500 | 700 | 700 |

3 | Break Elongation(%) | 200 | 200 | 300 | 300 | 400 | 400 |

4 | Stereo tensile strength | 400 | 320 | 450 | 370 | 500 | 420 |

5 | Dimensional stability,% | ±2 | |||||

6 | Bending at low temperature | Bending without crack at -35°C | |||||

7 | Vertical water flow rateNaN3/s Water pressure is 5KPa | 5.6 | 8.6 | 5.6 | 8.6 | 5.6 | 8.6 |

8 | Vertical water flow rateNaN3/s Water pressure is 5KPa | 15.2 | 18.2 | 15.2 | 18.2 | 15.2 | 18.2 |

Composite Dimple Geomembrane Property:

--Waterproofing and drainage: form a channel to get through water and gas freely;

--Sound insulation and vibration isolation;

--Chemical resistance, resist to plants’ root;

--Easy for construction

--Long lifetime.

Composite Dimple Geomembrane Application:

Highway and railway waterproofing system, underground waterproof, roof garden waterproof projects, etc.

- Q: How are earthwork products used in construction?

- Earthwork products, such as fill materials and aggregates, are commonly used in construction for various purposes. Fill materials, like soil and gravel, are used to create a solid foundation for buildings, roads, and other structures. They are used to level the ground, improve soil stability, and provide support for structures. Aggregates, which include crushed stones and sand, are used to create concrete and asphalt mixes that are essential for constructing foundations, pavements, and structural elements. Additionally, these earthwork products are used for landscaping, drainage systems, and erosion control measures in construction projects.

- Q: Are earthwork products suitable for landscaping projects?

- Yes, earthwork products are suitable for landscaping projects. Earthwork products, such as soil, rocks, and mulch, can be used to create and shape outdoor spaces, build retaining walls, create raised beds, improve soil quality, and enhance the overall aesthetics of a landscape. These products provide the foundation for various landscaping elements and can be tailored to meet the specific needs and design preferences of a project.

- Q: Why beginners or senior civil engineering and technical personnel are required to continue to learn civil engineering materials

- Civil engineering materials teaching materials mainly introduce the basic composition of civil engineering materials commonly used in civil engineering, material performance, quality requirements, testing methods

- Q: Are earthwork products suitable for use in dam construction?

- Yes, earthwork products are suitable for use in dam construction. Earthwork materials such as clay, soil, and rock fill are commonly used in the construction of dams to create embankments or as part of the foundation. These materials provide stability, strength, and resistance to water seepage, making them ideal for constructing dams that can hold large volumes of water. Additionally, earthwork products are readily available and cost-effective, making them a practical choice for dam construction projects.

- Q: Can earthwork products be used in stormwater filtration systems?

- Yes, earthwork products can be used in stormwater filtration systems. Earthwork products such as geotextiles, geogrids, and permeable pavers can help to filter and remove pollutants from stormwater runoff, improving water quality and reducing the impact on natural ecosystems. These products are designed to facilitate the filtration process by allowing water to pass through while trapping sediments, debris, and contaminants.

- Q: How do earthwork products contribute to soil stabilization?

- Earthwork products such as geotextiles, geogrids, and geocells play a vital role in soil stabilization by providing reinforcement, erosion control, and drainage. These materials are designed to increase the shear strength of the soil, prevent soil erosion, and enhance its load-bearing capacity. By distributing the forces exerted on the soil, these products help in reducing soil settlement, improving slope stability, and preventing landslides. Additionally, they promote water drainage, preventing waterlogging and the subsequent weakening of the soil. Overall, earthwork products act as a protective layer, enhancing the stability and longevity of the soil.

- Q: What are the long-term performance benefits of earthwork products?

- The long-term performance benefits of earthwork products include improved stability and strength of the soil, erosion control, enhanced drainage, and increased durability. These products provide long-lasting solutions that help to maintain the integrity of the earthwork projects over time.

- Q: What are the advantages of using geotextile mats in soil stabilization?

- There are several advantages of using geotextile mats in soil stabilization. Firstly, these mats act as a barrier between the soil and any applied loads, distributing the weight more evenly and reducing the risk of soil erosion. Secondly, they provide reinforcement to the soil, increasing its strength and stability, especially in areas prone to landslides or erosion. Additionally, geotextile mats allow water to pass through, preventing water buildup and improving drainage, which is crucial for maintaining soil integrity. Lastly, these mats are easy to install, cost-effective, and have a long lifespan, making them a practical solution for soil stabilization projects.

- Q: What are the different types of erosion control products for earthwork?

- There are several types of erosion control products for earthwork, including erosion control blankets, turf reinforcement mats, sediment control barriers, silt fences, and hydroseeding. These products are designed to prevent soil erosion and promote vegetation growth, ultimately protecting the earthwork site from erosion and sediment runoff.

- Q: Are earthwork products resistant to extreme temperature variations?

- Yes, earthwork products are generally resistant to extreme temperature variations. The natural materials used in earthwork products, such as soil and clay, have inherent thermal properties that allow them to withstand both hot and cold temperature fluctuations. However, it is important to note that specific earthwork products may have different levels of resistance depending on their composition and construction techniques.

Send your message to us

Composite Dimple Geomembrane for Civil Engineering Project Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords