Tri Dimensional Composite Drainage Geonet For Building

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5000 M2 m²

- Supply Capability:

- 280000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Tri Dimensional Composite Drainage Geonet:

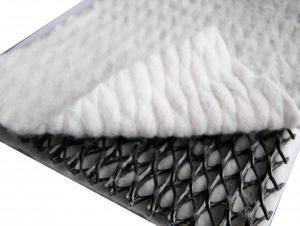

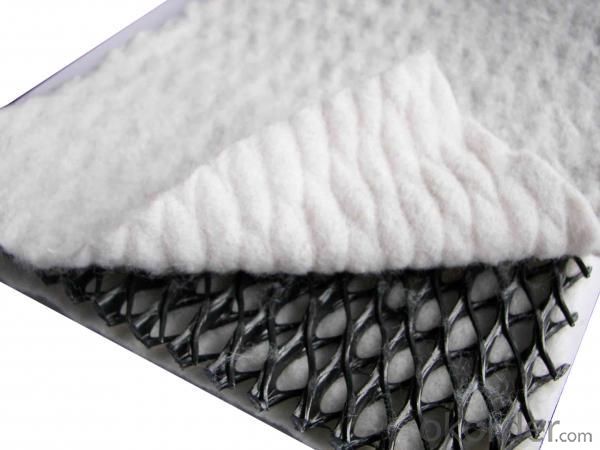

Tri-dimensional composite drainage geonet is made of a unique tri drimension geonet adhibit geotextile on both sides. It has the property of geotextile(filtration function) and geonet (drainage and protection) and provide a function system “filtration—drainage—protection”. The core of net with its unique tri-dimension structure can bear higher compressing load in construction and remain the certain thickness, provide good water conductivity.

Application of Tri Dimensional Composite Drainage Geonet:

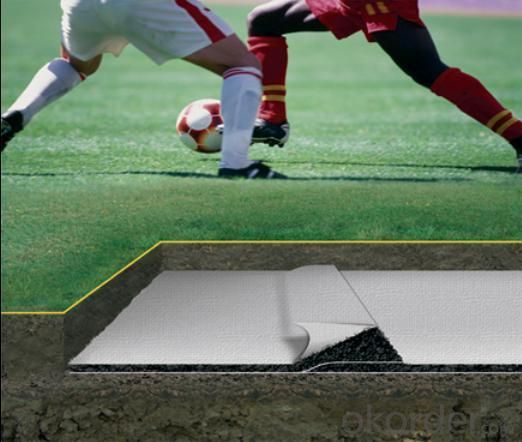

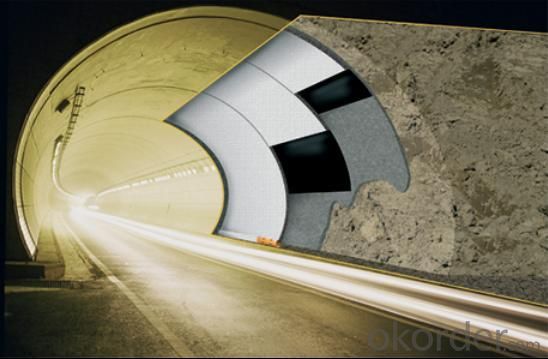

Landfill drainage; roadbed and road drainage; railway drainage ,tunnel drainage, underground structure drainage, the retaining back wall drainage, gardens and sports grounds drainage.

specifications and technical parameters of Tri dimensional composite drainage geonet:

Drainage network core | Units | Specifications | |||

Unit weight | g/m2 | 750 | 1000 | 1300 | 1600 |

Thickness OV=20kpa | mm | 5.0 | 6.0 | 7.0 | 7.6 |

Hydraulic conductivity | m/s | K×10ˉ4 | K×10ˉ4 | K×10ˉ4 | K×10ˉ4 |

Elongation | % | <50 | <50 | <50 | <50 |

Tensile strength (core network) | KN/m | 8 | 10 | 12 | 14 |

Geotextiles | g/m2 | 200-200 | 200-200 | 200-200 | 200-200 |

The contrast of Tri dimensional composite drainage geonet and natural grit drainage layer

Application | Tri-dimension composite geonet for drainage | Natural Gravel |

Conducting and discharging Water and gas | Pass through strict quality control production line and have stable performance and good property of conducting water | The traditional gravel have complex composition and its drainage property change with its attribute. Its actual drainage property is much lower laboratory data for its contains of sand and dust. |

Load/Protection | Light, no more extral load on geomembrane and waste. Anti-pull, anti-compress, anti-impact and can prevent geomembrane from damage | Pressure on the waste, the keen stone can puncture and damage geomembrane. Often need other safeguard, such as thicker geotextile. |

Function | Four functions: drainage, separation, filtration and protection | Only drainage function, easy be blocked, and need accessorial filtration system. |

Construction and installation | Fast installation, easy for construction, without heavy machinery and professionals. Construction speed is 5-10 times of gravel. | Slow installation, bulky and heavy, need heavy machinery. High cost and have more difficulties with slope degree is more than 1V:4H. |

Environment | Raw material is polyethylene, nontoxic, no pollution, 100% recyclable products. | Relatively speaking, the gravel is scarce and precious resources. The ecological environment will be destroied when people mine gravel. |

Durability | Good anti-erosion, antioxidation, anti-atmospheric media and rain water. It have long-term and the best drainage property if used them along with the geotextile. | Be easily blocked, has poor durability. |

- Q: How can sediment control products help in construction sites?

- Sediment control products can help in construction sites by effectively managing and minimizing the erosion and sedimentation that occurs during construction activities. These products, such as silt fences, sediment basins, and sediment logs, help to contain and filter sediment-laden runoff, preventing it from polluting nearby water bodies. By implementing sediment control measures, construction sites can comply with environmental regulations, protect water quality, and maintain a clean and safe working environment.

- Q: Can earthwork products be used for creating barrier walls?

- Yes, earthwork products can be used for creating barrier walls. These products, such as gabions, geotextiles, or retaining walls, are commonly employed in construction to provide effective barriers or support structures. They can be used for various purposes, including erosion control, flood protection, or creating barriers for noise reduction or privacy.

- Q: How do earthwork products compare to traditional construction materials in terms of strength?

- Earthwork products, such as soil, gravel, and rocks, typically do not have the same strength as traditional construction materials like concrete or steel. While earthwork products can be compacted and reinforced to some extent, they generally have lower compressive and tensile strengths. However, earthwork materials can provide sufficient strength for certain applications, particularly when used in geotechnical engineering or landscaping projects. Additionally, their availability and cost-effectiveness make them a popular choice for projects where high strength is not the primary requirement.

- Q: How are geocells used for load support in military installations?

- Geocells are used for load support in military installations by providing a stable and reinforced foundation for various structures and equipment. These three-dimensional honeycomb-like structures are filled with compacted soil or aggregate material, creating a strong platform that distributes weight evenly and prevents settling or shifting. This enables military installations to withstand heavy loads such as vehicles, aircraft, or temporary structures, ensuring operational efficiency and safety.

- Q: Are there any earthwork products specifically designed for agricultural projects?

- Yes, there are several earthwork products specifically designed for agricultural projects. Some common examples include drainage tiles, erosion control blankets, silt fences, and contour plowing techniques. These products and techniques help improve soil health, prevent erosion, manage water flow, and enhance overall agricultural productivity.

- Q: What are the common materials used in earthwork products?

- Common materials used in earthwork products include soil, gravel, sand, rocks, and clay. These materials are often used for construction purposes such as building foundations, roadways, embankments, and landscaping projects.

- Q: What are the different types of geocells available in the market?

- There are several types of geocells available in the market, including but not limited to cellular confinement systems made of high-density polyethylene (HDPE), geocellular filled with gravel or soil, and geocellular mats made of woven or non-woven geotextiles.

- Q: What are the key considerations when using geotextile bags for shoreline restoration?

- When using geotextile bags for shoreline restoration, there are several key considerations to keep in mind. Firstly, the location and condition of the shoreline should be thoroughly assessed to determine if geotextile bags are the appropriate solution. Factors such as wave action, water levels, and soil stability must be evaluated to ensure the bags can withstand the environmental conditions. Secondly, the selection of the right geotextile bag material is crucial. The bags should be made from high-quality, durable materials that are resistant to UV degradation, erosion, and punctures. The bag's permeability should also be considered to allow proper drainage while preventing the loss of fill material. Thirdly, the proper installation technique is essential for effective shoreline restoration. The bags should be placed in a strategic manner, considering factors such as slope stability, water flow patterns, and the desired shoreline shape. Adequate anchoring and secure connections between bags are important to ensure long-term stability and prevent displacement. Additionally, regular monitoring and maintenance of the geotextile bags are necessary. Periodic inspections should be conducted to check for any signs of damage, erosion, or settlement. Timely repairs or adjustments should be made to maintain the integrity of the bags and prevent further shoreline erosion. Overall, careful planning, proper material selection, correct installation, and ongoing maintenance are key considerations when using geotextile bags for shoreline restoration.

- Q: What are the safety considerations when using earthwork products?

- Some safety considerations when using earthwork products include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and sturdy footwear to protect against potential hazards like sharp edges or falling debris. It is important to follow proper lifting techniques to prevent back injuries, as some earthwork products can be heavy. Additionally, one should be cautious of working near unstable or unsupported soil, as it can lead to collapse or cave-ins. Regular inspections of the equipment and tools used for earthwork should also be conducted to ensure they are in good working condition, minimizing the risk of accidents.

- Q: What is the lifespan of geosynthetics in earthwork applications?

- The lifespan of geosynthetics in earthwork applications varies depending on the type of material, the specific application, and the environmental conditions. However, when used and installed correctly, geosynthetics can have a lifespan ranging from 20 to 100 years.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1998 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port,China |

| Export Percentage | 41-50% |

| No.of Employees in Trade Department | 5-10 People |

| Language Spoken: | English; Chinese; Russian; Spanish |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Tri Dimensional Composite Drainage Geonet For Building

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5000 M2 m²

- Supply Capability:

- 280000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches