Composite Geotextile Drainage Network for Architectural Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Composite Geotextile Drainage Network for Architectural Engineering

Description Of Composite Geotextile Drainage Network for Architectural Engineering

Composite material is a general term for the synthetic materials used in civil engineering. As a kind of civil engineering materials, it is to synthetic polymers, such as plastics, chemical fiber, synthetic rubber as raw material, made of various types of products, placed inside the soil, surface, or various kinds of soil play to strengthen or to protect the soil. The application of the technology of soil engineering synthetic materials will be divided into the type of the material of the soil, the soil, the soil, the special material and the composite. The special materials for the special materials include the soil engineering film bag, the soil engineering net。

Main Features of Composite Geotextile Drainage Network for Architectural Engineering

The advantages of the composite is that the weight is light, and the overall continuity is good (can be made into a large area of the whole), construction is convenient, high tensile strength, corrosion resistance and resistance to microorganisms. The disadvantage is that, without special treatment, anti ultraviolet ability, such as exposure to ultraviolet radiation, is easy to aging

Applications of Composite Geotextile Drainage Network for Architectural Engineering

1, for the stability of highway, railway roadbed.

2, used to bear the weight of the embankment and shallow water treatment.

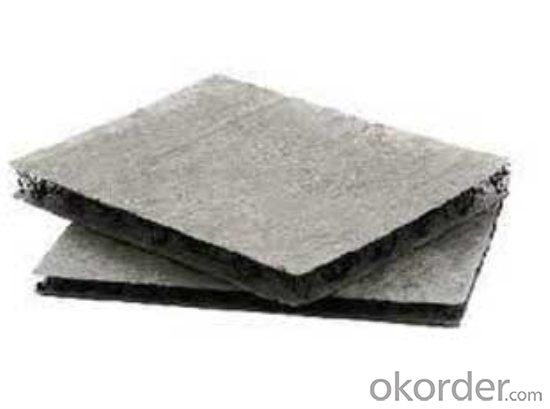

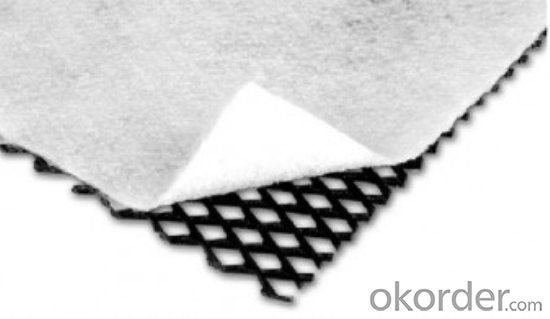

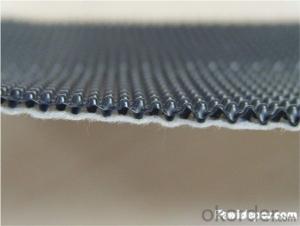

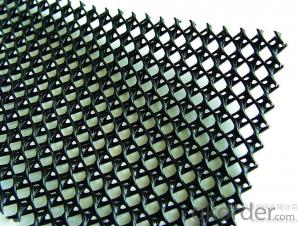

IMages of Composite Soil Drainage Network for Architectural Engineering

FAQ:

1. What are we supplying?

We are specialized in producing .geotextile , geocell, geogrid, geomembrane

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q: Can concrete pipes be used for drainage systems?

- Yes, concrete pipes can be used for drainage systems. Concrete pipes are commonly used in various drainage applications as they are strong, durable, and provide excellent resistance to various environmental and chemical factors. Additionally, they have a smooth inner surface that allows for efficient flow of water, making them suitable for drainage systems.

- Q: Can earthwork products be used in sound barriers along highways?

- Yes, earthwork products such as soil, rocks, and other natural materials can be used in sound barriers along highways. These materials can be shaped and arranged to create effective noise barriers that help reduce the impact of highway noise on nearby communities.

- Q: Can earthwork products be customized to specific project requirements?

- Yes, earthwork products can be customized to specific project requirements. Various factors such as soil type, site conditions, and project specifications can influence the customization of earthwork products. By considering these factors, earthwork products can be tailored to meet the specific needs and requirements of a particular project, ensuring optimal performance and efficiency.

- Q: What is the purpose of using geotextiles in earthwork?

- The purpose of using geotextiles in earthwork is to enhance the stability, strength, and durability of the soil by providing reinforcement, filtration, and separation functions. Geotextiles help control soil erosion, improve drainage, and prevent the mixing of different soil layers, ultimately improving the overall performance and longevity of earthwork structures.

- Q: What are the different types of geotextile bags available for erosion control?

- There are several different types of geotextile bags that can be used for erosion control, including sandbags, silt bags, sediment bags, and geotextile tubes or mattresses. Each type of bag is designed to address specific erosion control needs, such as preventing soil erosion, filtering sediment, or stabilizing slopes. These bags are typically made of durable geotextile fabric that allows water to pass through while retaining soil particles, effectively reducing erosion and promoting vegetation growth.

- Q: Can geosynthetic reinforcement be used for soil stabilization?

- Yes, geosynthetic reinforcement can be used for soil stabilization. Geosynthetics, such as geotextiles or geogrids, are commonly employed to improve the mechanical properties of soil, increase its load-bearing capacity, and prevent soil erosion. These materials are often installed in the soil as layers or grids to enhance its stability, reduce settlement, and enhance overall performance in various construction and civil engineering applications.

- Q: How do geogrids help in soil stabilization?

- Geogrids help in soil stabilization by providing reinforcement and improving the overall strength and stability of the soil. They are typically made of high-strength materials and are placed within the soil to create a network of interlocking grids. This helps to distribute and transfer the loads and stresses applied to the soil, preventing soil movement, erosion, and settlement. Geogrids also enhance the load-bearing capacity of the soil, making it more suitable for construction projects and preventing potential failures.

- Q: Can earthwork products be used in underground storage tank construction?

- Yes, earthwork products can be used in underground storage tank construction. These products, such as compacted soil, gravel, and geosynthetic materials, can be utilized for various purposes in underground storage tank construction, including providing stable foundations, preventing soil erosion, and enhancing the structural integrity of the tank.

- Q: Are there any specific earthwork products available for slope stabilization?

- Yes, there are specific earthwork products available for slope stabilization. These products include geotextiles, geogrids, and erosion control blankets, which are designed to prevent soil erosion and provide stability to slopes. Additionally, techniques such as terracing and retaining walls can also be used for slope stabilization.

- Q: What are the benefits of using geocells in green infrastructure projects?

- Geocells offer several benefits in green infrastructure projects. Firstly, they provide an effective solution for soil stabilization, preventing erosion and promoting the growth of vegetation by creating a stable base. Secondly, geocells enhance stormwater management by allowing water infiltration and reducing runoff, thereby mitigating the risk of flooding. Additionally, geocells can be filled with a variety of materials like soil, gravel, or recycled materials, making them versatile for different project needs. Lastly, these cellular confinement systems are cost-effective, durable, and easy to install, making them an ideal choice for greener and sustainable infrastructure development.

Send your message to us

Composite Geotextile Drainage Network for Architectural Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords