HDPE Geocomposite Drainage for Road Contruction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

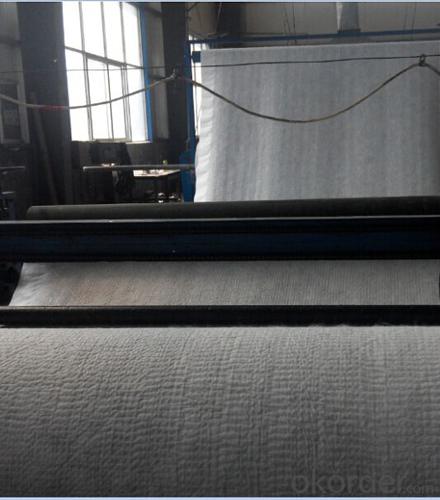

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

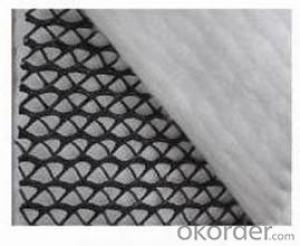

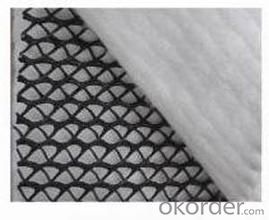

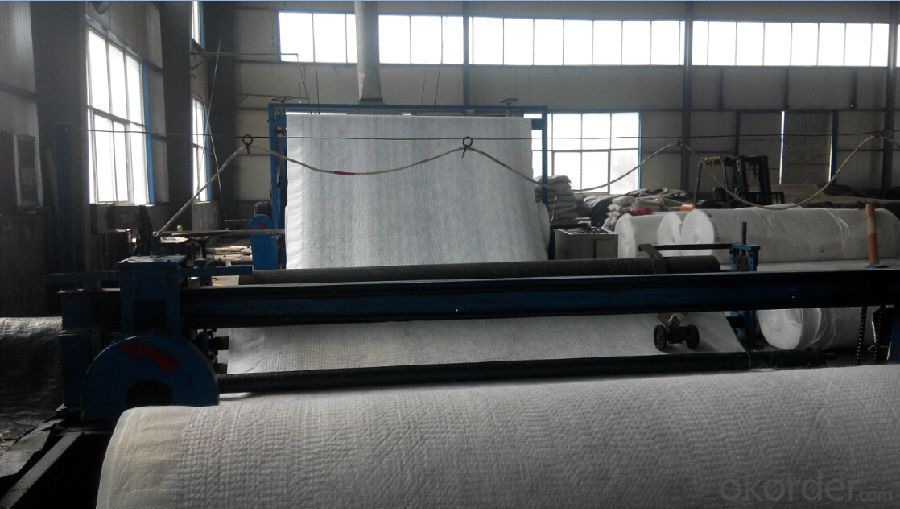

HDPE Drainage Geocomposite / Composite drainage geonet

Description :

for drainage is made of a unique trmension geonet adhibited geotextile on both sides.it has the property of geotextile(filtration function ) and geonet (drainage and protection ) and provide a function system"filtration-drainage-protection".the core of net with its unique tr-dimension structure can bear higher compressing load in construction and remain the certain thickness,

provide good water conductivity.

Application:

1) Landfill drainage;

2) roadbed and road drainage;

3) railway drainage;

4) tunnel drainage,

5) underground structure drainage,

6) the retaining back wall drainage;

7) gardens and sports ground drainage

Features:

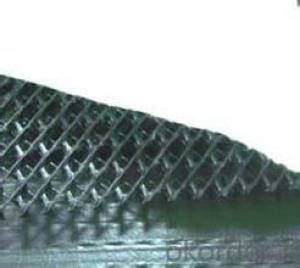

1)Excellent drainage function, can bear long time hige press load

2)High tensile and shear strength

3Reduce the rate geotextile embedding into the core of geonet, can protect long time stable water conductivity

4)Tri-dimension composite geonet for drainage can bear more than 2000kpa compression load

5)Its anti-compression capacity is much larger than common geonet for drainage

6) Certificate :ISO14001:2004, ISO9001:2008

Specifications and technical parameters:

Drainage network core | units | Specification | ||||

Unit weight | g/m2 | 750 | 1000 | 1300 | 1600 | |

Thickness | Mm | 5.0 | 6.0 | 7.0 | 7.6 | |

Hydraulic conductivity | m/s | kx10-4 | Kx10-4 | Kx10-4 | Kx10-4 | |

Elongation | % | 50 | 50 | 50 | 50 | |

Tensile strength (core netwaork) | kN/m | 8 | 10 | 12 | 14 | |

Geotextile | g/m2 | Heavier grades of geotextiles can be bonded to geonet on request | ||||

Usages:

In the railway, highway and other transportation infrastructure, drainage system safety and the service life

of the project and its have inseparable relationship, in which the geotextile material is an important part

of drainage system, the drainage effect of 3D composite drainage net is particularly notable. mainly

used for tunnels, municipal engineering, reservoir, revetment in drainage engineering.

FAQ

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples if you need.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

- Q: Are earthwork products suitable for bridge approach embankments?

- Yes, earthwork products are suitable for bridge approach embankments. Earthwork materials, such as soil, clay, or gravel, can be used to construct stable embankments that support the bridge approach. These materials can be compacted and shaped to provide a solid foundation and slope for the bridge approach, ensuring its stability and longevity.

- Q: How are geotextile tubes used in shoreline restoration projects?

- Geotextile tubes are used in shoreline restoration projects to create barriers or structures that help protect the shoreline from erosion caused by waves, tides, and storms. These tubes are often filled with sand or sediment and placed along the shoreline to form dunes or breakwaters, providing stability and preventing further erosion. Additionally, the geotextile material allows for water drainage while retaining the sediment, promoting natural vegetation growth and enhancing the overall ecological function of the shoreline.

- Q: What is the lifespan of geocomposite drainage systems?

- The lifespan of geocomposite drainage systems can vary depending on factors such as the quality of materials used, installation techniques, and the conditions in which they are used. However, with proper installation and maintenance, geocomposite drainage systems can have a lifespan of 25 to 50 years or more.

- Q: Can geotextile bags be used for erosion control?

- Yes, geotextile bags can be used for erosion control. These bags are commonly filled with soil or sand and placed in areas prone to erosion, such as riverbanks or shorelines, to stabilize the soil and prevent erosion by absorbing and dissipating the energy of moving water.

- Q: How do earthwork products contribute to site development?

- Earthwork products, such as soil, gravel, and rocks, play a crucial role in site development. These materials are used for various purposes, including grading and leveling the land, creating structural foundations, building roads and pathways, and controlling erosion. Additionally, earthwork products are essential for improving drainage systems, creating retaining walls, and enhancing overall site aesthetics. In short, these products provide the necessary groundwork for successful and sustainable site development projects.

- Q: What are the different edge profiles available for earthwork products?

- Some of the different edge profiles available for earthwork products include straight edges, beveled edges, rounded edges, chamfered edges, and sloping edges. These profiles can be customized based on the specific requirements and aesthetics of the project.

- Q: What are the different surface treatments available for earthwork products?

- There are several surface treatments available for earthwork products, including but not limited to: soil stabilization, erosion control, compaction, grading, and surface sealing. These treatments help to ensure the stability and longevity of the earthwork products, while also protecting them from environmental factors such as water erosion and soil movement.

- Q: What are the advantages of using geotextile fabrics in landscaping projects?

- Geotextile fabrics offer several advantages in landscaping projects. Firstly, they act as a barrier that prevents weed growth, reducing the need for herbicides and manual weeding. Secondly, these fabrics can effectively control soil erosion by stabilizing the soil and preventing it from washing away during heavy rainfall or irrigation. Additionally, geotextile fabrics can provide reinforcement to weak soil, improving its stability and load-bearing capacity. They also facilitate water drainage, preventing waterlogging and promoting healthy plant growth. Finally, these fabrics are permeable, allowing air and nutrients to reach plant roots while retaining moisture in the soil. Overall, the use of geotextile fabrics in landscaping can enhance the longevity and sustainability of outdoor projects.

- Q: How do geotextile mats help with slope stabilization?

- Geotextile mats help with slope stabilization by providing reinforcement and erosion control. They are placed on the slope surface to prevent soil erosion, retain soil particles, and promote vegetation growth. The mats distribute the weight of the soil and increase its shear strength, thereby reducing the risk of slope failure. Additionally, they allow water to drain through while retaining fine soil particles, preventing the loss of soil and protecting the slope from erosion caused by water runoff.

- Q: What are the key considerations when using geosynthetic materials in dam construction?

- Some key considerations when using geosynthetic materials in dam construction include the type and quality of the geosynthetic material being used, its compatibility with the surrounding soil and rock, its ability to withstand the hydraulic pressures and stresses imposed by the dam, its durability and resistance to aging and degradation, its installation and construction techniques, and its long-term performance and maintenance requirements. Additionally, factors such as cost-effectiveness, environmental impact, and regulatory compliance should also be taken into account when considering the use of geosynthetics in dam construction.

Send your message to us

HDPE Geocomposite Drainage for Road Contruction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords