Geonets/Geocomposite Drainage Liners for Erosion Control

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

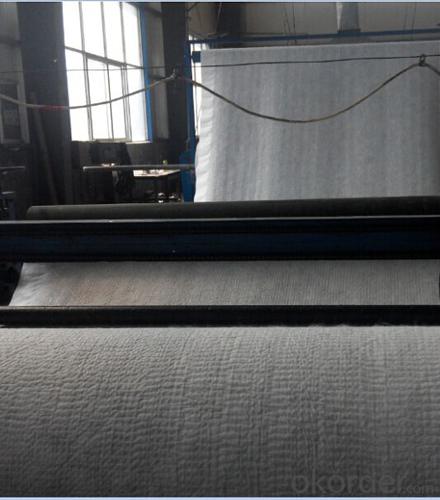

Geonets/Geocomposite Drainage Liners for Erosion Control

Introduction

Geo-Net, also called drainage net, is a cost effective alternative to aggregate drains in containment systems. Geo-Nets take up less space than aggregate drains and can help to maximize volume in landfills and surface impoundments. Geo-Nets are commonly used between two geomembrane liners as part of a leak detection system. When placing Geo-Nets with geotextiles it is often effective to have the geotextile bonded to the Geo-Net in the factory. Geocomposites usually have a geotextile bonded to one, or to both sides of a Geo-Net. This creates a drainage structure that can be used between layers of geomembranes, and in many other unusual situations. The geotextile layers prevent the movement of soil fines into the Geo-Net drainage path that could lead to clogging and drainage failure.

Main features Geonet-Geotextile Drainage Geocomposite

1. Row water-borne strong (equivalent to one meter thick gravel drainage).

2. Tensile strength to be high .

3. Reduce geotextiles net core chance of embedded, maintain a long-term and stable drainage.

4. Long-term under great pressure and load (can bear about 3000Ka compression load)

5. Corrosion resistance, acid and alkali resistant, long service life.

6. Construction is convenient, shorten the construction period, lower cost.

8. Excellent drainage function, can bear long time high press road

9. High tensile and shear strength

10.Can bear more than 2000KPa compression load

11.anticompression capacity is much larger than common geonet for drainage.

Performance

1. Excellent drainage and sustain high compression loading

2. Highest tensile strength and shearing strength

3. Cut down ratio of geotextile into geonet and keep stable permeability in a long time

4. It can bear compression loading over 2000Kpa

5.Its compressive strength far exceeds general drainage geonet

Application

Using for drainage such as refuse landfill, roadbed & road surface, railway, tunnel, underground structure, retaining wall, garden, sports ground and so on.

Technical Data

Drainage network core | units | Specification | ||||

Unit weight | g/m2 | 750 | 1000 | 1300 | 1600 | |

Thickness | Mm | 5.0 | 6.0 | 7.0 | 7.6 | |

Hydraulic conductivity | m/s | kx10-4 | Kx10-4 | Kx10-4 | Kx10-4 | |

Elongation | % | 50 | 50 | 50 | 50 | |

Tensile strength (core netwaork) | kN/m | 8 | 10 | 12 | 14 | |

Geotextile | g/m2 | Heavier grades of geotextiles can be bonded to geonet on request | ||||

FAQ

1.How about the delivery time?

Lead time since receipt of 30% T/T deposit payment: 2-3 weeks. (Samples will be prepared within 3 days.)

2. What kind of payments does jenor support?

T/T, L/C, Cash are accepted.

3. What's are the MOQ?

We can according to your condition to set the MOQ. and we can provide you samples for quality inspection before the mass production.

4. Do you charge for the samples?

Accordeing to our company policy, the samples are free, we only charge the freight fee.

5. Can you produce according to customers' design?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: Can earthwork products be used for constructing horse riding arenas?

- Yes, earthwork products such as gravel, sand, and topsoil can be used for constructing horse riding arenas. Gravel can provide a stable base, sand can offer cushioning and traction, and topsoil can be used for leveling and creating a suitable surface for the horses.

- Q: Can geomembranes be used for secondary containment?

- Yes, geomembranes can be used for secondary containment. They are impermeable barriers that can effectively contain and prevent the escape of liquids or hazardous materials. Geomembranes are commonly used in various industries, such as oil and gas, chemical, and waste management, to provide an additional layer of protection against potential leaks or spills.

- Q: How do geosynthetic materials contribute to sustainable construction practices?

- Geosynthetic materials contribute to sustainable construction practices by offering various benefits such as improved soil stabilization, erosion control, and efficient drainage systems. These materials help minimize the use of natural resources like aggregates, reduce construction time, and enhance the overall durability of infrastructure. By providing cost-effective and eco-friendly solutions, geosynthetics promote sustainable development and reduce the environmental impact of construction projects.

- Q: What is the purpose of using silt fences in earthwork projects?

- The purpose of using silt fences in earthwork projects is to control erosion and sedimentation by trapping sediment-laden runoff water and allowing it to slowly filter through the fence, preventing soil erosion and protecting nearby water bodies from contamination.

- Q: What are the benefits of using geotextile tubes for land reclamation projects?

- Geotextile tubes offer several benefits for land reclamation projects. Firstly, they provide a cost-effective solution by utilizing locally available fill material instead of importing expensive fill materials. Secondly, they are highly efficient in dewatering and solidifying the sediments, reducing the volume and weight of material to be disposed of. Additionally, geotextile tubes have a small environmental footprint as they minimize disturbance to surrounding habitats and ecosystems. Lastly, they provide stability and erosion control, preventing soil erosion and protecting the newly reclaimed land against wave action and currents.

- Q: What are the specific applications of geocells in earthwork projects?

- Geocells have specific applications in earthwork projects such as soil stabilization, erosion control, slope protection, and load support. They are used to reinforce and stabilize weak soils by confining and interlocking the fill material, preventing lateral movement. Geocells also help in preventing soil erosion by providing a permeable barrier that allows water to flow through while preventing soil particles from being washed away. Additionally, these cells are utilized for slope protection, preventing soil displacement and erosion on steep slopes. Lastly, geocells are employed to provide load support and improve the bearing capacity of the soil, making them useful in constructing access roads, parking lots, and other heavy-duty applications.

- Q: How can geosynthetic panels be used in bridge abutments?

- Geosynthetic panels can be used in bridge abutments to provide reinforcement and stability to the soil. These panels are typically placed behind the abutment wall and act as a reinforcement layer, preventing soil erosion and retaining the backfill material. This helps to distribute the load and reduce the potential for settlement or failure of the abutment. Additionally, the geosynthetic panels can also enhance the overall strength and durability of the bridge abutment, making it more resistant to external forces such as soil movement or water pressure.

- Q: Can earthwork products be used for constructing outdoor fire pits?

- Yes, earthwork products can be used for constructing outdoor fire pits. These products, such as rocks, stones, and soil, can be used to create a sturdy and safe base for the fire pit. Additionally, they can be used to build the walls and surround of the fire pit, providing a natural and aesthetically pleasing design.

- Q: What is the purpose of using geotextile bags in erosion control structures?

- The purpose of using geotextile bags in erosion control structures is to provide stabilization and protection against erosion by trapping sediment and promoting vegetation growth, ultimately preventing soil erosion and maintaining the integrity of the surrounding landscape.

- Q: Can earthwork products be used for retaining walls?

- Yes, earthwork products, such as soil, gravel, and drainage materials, can be used for constructing retaining walls. These materials are often used to provide stability and support to the wall structure, preventing soil erosion and maintaining the integrity of the wall.

Send your message to us

Geonets/Geocomposite Drainage Liners for Erosion Control

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords