1 4 Inch Aluminum Plate Weight

1 4 Inch Aluminum Plate Weight Related Searches

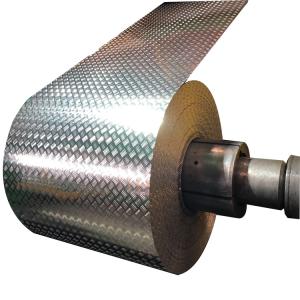

1 4 Aluminum Plate Weight Weight Of 1 4 Aluminum Plate 1/4 Aluminum Plate Weight Weight Of 1/4 Aluminum Plate 1 4 Inch Aluminum Plate Weight Of Aluminum Plate 1 4 Inch Thick Aluminum Plate 1 2 Aluminum Plate Weight 1 4 Aluminum Plate Price 1 4 Thick Aluminum Plate 1 4 Inch Aluminum Diamond Plate 4 Inch Aluminum Plate 1 4 Aluminum Plate 1 8 Aluminum Plate Weight 3 4 Inch Aluminum Plate 1/4 Inch Aluminum Plate Strength Aluminum Plate Weight Chart 1/4 Inch Aluminum Plate Aluminum Floor Plate Weight Aluminum Diamond Plate Weight 4 Mm Aluminum Plate 1 4 Aluminum Diamond Plate Price Weight Of 1/2 Aluminum Plate 1 4 In Aluminum Plate 4 X 8 X 1 4 Aluminum Plate 1 4 Aluminum Diamond Plate Aluminum Checker Plate Weight 4 X 4 Aluminum Plate 1/8 Aluminum Plate Weight 1/4 Inch Thick Aluminum Plate1 4 Inch Aluminum Plate Weight Supplier & Manufacturer from China

1/4 Inch Aluminum Plate Weight is a type of aluminum product known for its lightweight and high strength properties. This particular plate weight is 1/4 inch thick, making it suitable for various applications where a balance of weight and durability is required.The 1/4 Inch Aluminum Plate Weight is commonly used in industries such as construction, automotive, and aerospace due to its ability to withstand high stress and maintain its structural integrity. It is also utilized in various engineering projects and as a component in the manufacturing of different machinery and equipment. This product is favored for its corrosion resistance and its ability to be easily shaped and formed into various configurations, making it a versatile choice for a wide range of applications.

Okorder.com is a leading wholesale supplier of 1/4 Inch Aluminum Plate Weight, offering a vast inventory of this product to cater to the needs of various industries. With a commitment to providing high-quality materials at competitive prices, Okorder.com ensures that customers have access to reliable and durable 1/4 Inch Aluminum Plate Weight for their projects and applications.

Hot Products