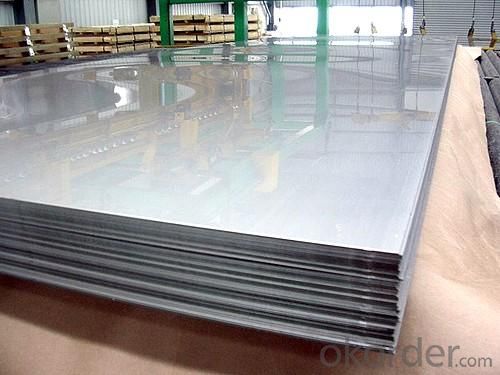

4x8 Grate Hot Sale Alloy 1100 1050 1060 3003 3004 5052 8011 Solid Aluminum Sheet Aluminum Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Grade: | Temper: | Type: | |||

| Application: | Thickness: | Width: | |||

| Surface Treatment: | Alloy Or Not: | Place of Origin: | |||

| Brand Name: | Model Number: | Class: | |||

| Color: | Alloy number: |

Packaging & Delivery

| Packaging Detail: | aluminium sheet Standard Package Wooden,Plastic,Paper Package |

| Delivery Detail: | 10-20days after deposit |

Specifications

aluminium sheet

1.Good strength of extension

2.Better tensile yield strength

3.Best elongation

aluminium sheet

Supplier the best quality of aluminium sheet

Advantages:

1.Good strength of extension

2.Better tensile yield strength

3.Best elongation

Applications:

chemical process plant equipment,food industry containers,architectural flashings, lamp reflectors, cable sheathing

Specification:

Main Products | Alloy Number | Hot rolling finial Thickness | Cold mill finial Thickness | Hot rolling finial Width | Cold mill finial Width |

1xxx Series | 1235 1050 1060 1100 | 2-8mm | 0.1-0.5mm | 900-2400mm | 1000-2400mm |

3xxxSeries | 3003 3004 3104 | 2-8mm | 0.1-0.5mm | 900-2400mm | 1000-2400mm |

5xxxSeries | 5052 5182 5083 5005 5754 | 2-8mm | 0.1-0.5mm | 900-2400mm | 1000-2400mm |

8xxxSeries | 8079 8011 | 2-8mm | 0.1-0.5mm | 900-2400mm | 1000-2400mm |

- Q: How do you prevent warping of aluminum sheets during bending?

- One way to prevent warping of aluminum sheets during bending is by using proper techniques and tools. This includes using the correct bending radius, ensuring even distribution of pressure along the sheet, and employing a suitable clamping method to hold the sheet in place during the bending process. Additionally, preheating the aluminum sheet can help to reduce the likelihood of warping.

- Q: When zinc dust and sulfur dust are combined in certain proportional ratios and ignited, a violent exothermic reaction occurs. Because the reaction only depends on two components; zinc and sulfur, but not oxygen, the reaction has all of the components that it needs within the mixture. The same is also true for a mixture of magnesium and sulfur.However, the same reaction does not occur with iron and sulfur. Instead, the mixture reacts slowly over a period of a few minutes rather than flashing to smoke in less than a second. Now for my questions:1: If aluminum and sulfur were combined in the same proportional ratios as the zinc and the magnesium mixtures were, would the reaction be as fast as the zinc and the magnesium mixtures? Why or why not?2: What properties of the different metals used in these mixtures makes them behave so differently?

- 1. This depends on the aluminium particle size and it's quality as Al is normally coated with an oxide layer that protects the Al metal underneath. Assuming that the Al powder was good stuff, it should react as violently as the Zn and Mg mixtures. Why .. because it is a very reactive metal ... see further info below. However I needed tried it. 2. The difference is really about the reactivity. Iron, although a reactive metal, is far less reactive than Mg,Al, and Zn. I have tried the zinc and sulphur a number of times and it is really quite violent. With a fair quantityof reactants in the lab it produced an excellent mushroom smoke cloud. I've also seen the Al reactivity demonstrated by a mad Chemistry prof from Nottingham University. He mixed Al powder into a paste with liquid oxygen and ignited it! Wow ... what a reaction.I shall never forget it although it was about 35 years ago!

- Q: What is the standard thickness of aluminum sheets used for constructing carports or garages?

- <p>The thickness of aluminum sheets commonly used for carports or garages typically ranges from 0.022 to 0.032 inches (0.56 to 0.81 mm). This range provides a balance between strength and cost-effectiveness. Thicker sheets offer greater durability and resistance to weathering, while thinner sheets are more affordable but may require more maintenance over time. The specific thickness chosen often depends on the design requirements, local weather conditions, and the intended lifespan of the structure.</p>

- Q: What characteristics distinguish aluminum sheets from other types of sheets?

- <p>Aluminum sheets are lightweight, corrosion-resistant, and have excellent thermal and electrical conductivity. They are commonly used in construction, automotive, and packaging industries. In contrast, other types of sheets, such as steel sheets, are heavier and stronger but less resistant to corrosion. Plastic sheets are lightweight and flexible but have lower strength and thermal conductivity. Copper sheets offer high thermal and electrical conductivity but are more expensive and less resistant to corrosion than aluminum. Each type of sheet has unique properties that make it suitable for specific applications.</p>

- Q: What are the different methods of surface cleaning for aluminum sheets?

- Aluminum sheets can be cleaned using various methods, each with its own advantages and suitability for different cleaning needs. One method is mechanical cleaning, which involves using techniques like brushes, abrasive pads, sandpaper, or a wire brush to remove dirt, stains, and oxidation from the surface. However, caution must be taken to avoid scratching the surface. Chemical cleaning, on the other hand, utilizes specific cleaning agents or solutions designed to dissolve or remove dirt, grease, oil, or other contaminants from aluminum surfaces. The choice of cleaning agent depends on the type of dirt or stain to be removed. High-pressure water cleaning is a method that employs a strong water jet to dislodge dirt or grime from the aluminum surface. It works well for removing loose debris or light dirt from larger areas, but may not be effective for heavily soiled surfaces. Steam cleaning involves using high-temperature steam to loosen dirt, grime, or other contaminants, making them easier to wipe or rinse away. It is versatile and suitable for both small and large surfaces. Another specialized method is electrolytic cleaning, which uses an electric current to remove contaminants. The aluminum sheet is immersed in a cleaning solution, and the electric current attracts the contaminants to a sacrificial electrode, leaving the sheet clean. However, this method requires specialized equipment and expertise. When choosing the appropriate cleaning method, it is important to consider the specific requirements, condition of the sheet, and desired level of cleanliness. Testing the chosen method on a small, inconspicuous area is also advisable to avoid potential damage.

- Q: you can turn in aluminum cans for cash some are called golden goats

- Aluminum okorder

- Q: How is the coated aluminum mirror plate produced?

- Covered film means the protective film on the surface of the protective materialMirror refers to the aluminum plate after polishing and other processes to deal with reflective rate, or gloss hundred percent effectAluminium plate is raw materialAs for the production process, the aluminum plate is cleaned and pretreated,Then the surface polished, and then plating or coating, transparent UV coloring. Become black mirror, blue mirror and other effectsFinally, the surface is covered with a plastic sticky protective film, namely a laminated mirror aluminum plate

- Q: My aluminum storm windows are wasting energy in my home, however, the $7000 estimate to replace them is beyond (well beyond) my comfort zone.I know aluminum is a great conductor of hot and cold. I was considering cleaning the frames, and then coating them with a brush on clear or possibly white liquid rubber to reduce the conductivity. Any idea as to how much benefit I'll realize? Is flammability going to be an issue?I need some solid answers please. Trolls go get your two points elsewhere.Thanks.Your help is much appreciated.

- Plastic coating will not stick to aluminum well. You will have to sand it first then use a aluminum metal primer. This is very labor intensive and you would be better off making new frames from wood or vinyl

- Q: I saw a guy on ebay take a washed out paint can fill it full of lighted charcoal bricks and a tin can in the middle. He was melting aluminum cans in there then pured it into a mold. Does this really work and does anyone have any good ideas on how else to do this?

- Aluminum alloys melt at around 1200 degrees, aluminum cans maybe somewhat lower, but I doubt a tin can would hold up long enough to melt much aluminum, and you would need to be very careful, any moisture in your mold will cause the aluminum to literally explode back into your face. I am not saying it couldn't be done, but you really would need lots of safety equipment before trying it.

- Q: which is the best bonding method for aluminum sheet and plastic?

- smear glue, there is a glue special for the bonding of plastic and steel materials.

Send your message to us

4x8 Grate Hot Sale Alloy 1100 1050 1060 3003 3004 5052 8011 Solid Aluminum Sheet Aluminum Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords