4 Foot Aluminum Sheets - High Quality Aluminum Alloy 6061 with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Thick Alloy 6061 with High Quality and Best Price Description:

Aluminium Thick Alloy 6061 with High Quality and Best Price is for Construction material with good ductility, polishing ability and corrosion resistance, good electrolytic oxidation, suitable for welding. Have good plasticity qualities in an annealed state suitable when hardened. Very good corrosion resistance, this material is not inclined to stress corrosion cracking. Cutting tool workability in an annealed state is not suitable but is acceptable in a hardened temper. Used for medium strength components with long operation schedules in temperatures from 50°C up to 70°C, applications requiring specific technological properties, corrosion resistance, aesthetic features, when in contact with food, high specification aviation and automotive components. Typical product applications include: airplane cabins, helicopter cockpits, floor coverings, door frames, safety barriers, escalators, furniture, rivet stems, cranes and columns.

2.Main Features of Aluminium Thick Alloy 6061 with High Quality and Best Price:

Good Ductility

Polishing Ability

Corrosion Resistance

Competitive Price

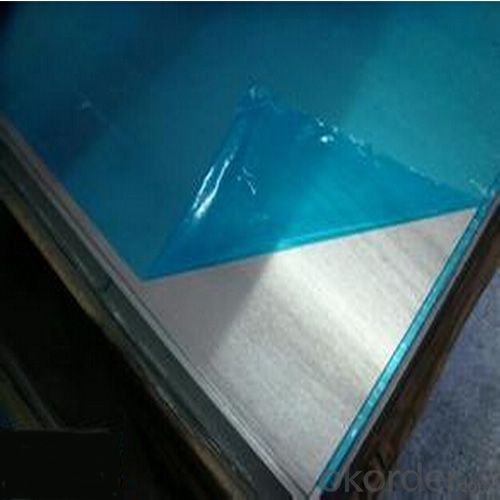

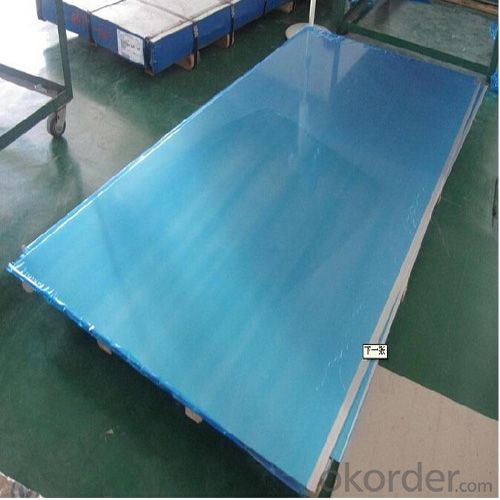

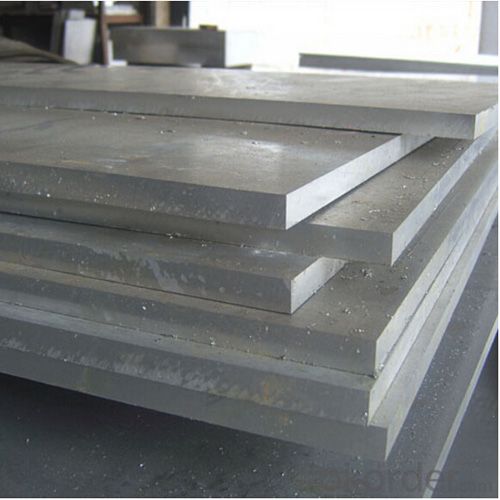

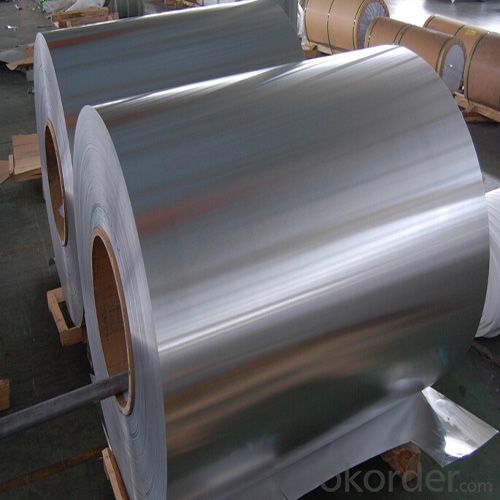

3. Aluminium Thick Alloy 6061 with High Quality and Best Price Images:

4. Aluminium Thick Alloy 6061 with High Quality and Best Price Specification:

Standard | GB/T3190-2008, GB/T3880-2006, ASTM B209, JIS H4000-2006 .etc |

Thickness | 3-12mm aluminium 5050 H38 |

Width | 1250mm 1000mm or as your requirements |

Length | 3000mm 5800mm or as your requirements |

MOQ | 10 Ton |

Package | Standard export package, by wooden box or as require |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

- Q: This is kind of odd, but if a volcano erupted and the lava dripped into an aluminum can, would the can melt? Would the lava harden and cool in it?

- Temperature of lava - 700 degrees Celsius. Melting point of aluminum - 660 degrees Celsius. I'll let you figure out if the can would melt...

- Q: Can 101 aluminum sheets be painted with automotive-grade finishes?

- Absolutely! It is completely possible to paint 101 aluminum sheets using automotive-grade finishes. These finishes are specifically formulated to stick to different surfaces, including aluminum. However, it is crucial to adequately prepare the aluminum sheets prior to painting in order to achieve optimal adhesion and long-lasting durability of the finish. This might entail cleaning the surface, eliminating any preexisting coatings or impurities, and applying a suitable primer. Furthermore, it is highly advisable to adhere to the manufacturer's instructions for the specific automotive-grade finish being utilized, as they may provide specific guidelines and recommendations for applying the finish to aluminum surfaces.

- Q: What is the typical price range for aluminum sheets?

- The typical price range for aluminum sheets can vary depending on factors such as size, thickness, and quality. However, generally speaking, aluminum sheets can range anywhere from $0.25 to $3 per square foot.

- Q: Fiber laser cutting machine and carbon dioxide laser cutting machine, which thin aluminum plate effect is better?

- If it is a thin aluminum plate, it is better to use the fiber laser cutter. Fiber laser cutting machine is mainly to cut thin metal, CO2 cutting machine is mainly cutting non-metallic or very thick metal. You can see the families:

- Q: Can aluminum sheets be bent into complex shapes?

- Yes, aluminum sheets can be bent into complex shapes due to their malleability and ductility. With the appropriate tools and techniques, aluminum sheets can be formed into intricate and customized designs, making them versatile for various applications.

- Q: Can aluminum sheets be used for interior design purposes?

- Yes, aluminum sheets can be used for interior design purposes. They are versatile, lightweight, and durable materials that can be used for various applications such as wall cladding, ceilings, countertops, backsplashes, and decorative accents. Aluminum sheets offer a modern and sleek aesthetic, and their availability in different finishes and colors allows for customization to fit various design styles and preferences.

- Q: Can aluminum sheet be painted or coated after fabrication?

- Yes, aluminum sheet can be painted or coated after fabrication. Aluminum is a versatile material that can be easily painted or coated to enhance its appearance or provide additional protection. The process involves preparing the surface by cleaning and removing any contaminants, followed by applying a primer to improve adhesion. After the primer has dried, a topcoat of paint or coating can be applied to achieve the desired color or finish. The type of paint or coating used will depend on the intended use and the specific requirements of the application. Overall, painting or coating aluminum sheet after fabrication is a common practice and can greatly enhance its aesthetics and durability.

- Q: What is the typical thermal conductivity of aluminum sheets?

- Aluminum sheets usually exhibit a thermal conductivity ranging from 205 to 230 watts per meter-kelvin (W/mK). Thanks to this remarkable thermal conductivity, aluminum serves as an exceptional conductor of heat. Hence, it finds widespread usage in various applications that prioritize efficient heat transfer, including heat sinks, power transmission lines, and cooking utensils.

- Q: Can aluminum sheets be used in construction?

- Yes, aluminum sheets can be used in construction. They are commonly used for roofing, siding, and structural applications due to their lightweight, corrosion-resistant, and durable properties.

- Q: What's the difference between 6061 aluminum plate, 7075 aluminium plate and 6063 aluminum plate?

- Simply put, 6061 and 6063 belong to the 6 series, 6061 hardness in 90HB 6063 in 80HB, suitable for brazing, surface oxidation treatment is better,

Send your message to us

4 Foot Aluminum Sheets - High Quality Aluminum Alloy 6061 with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords