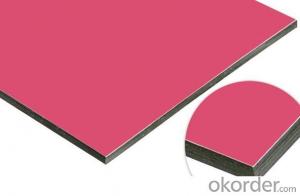

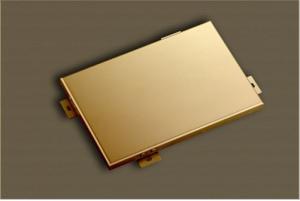

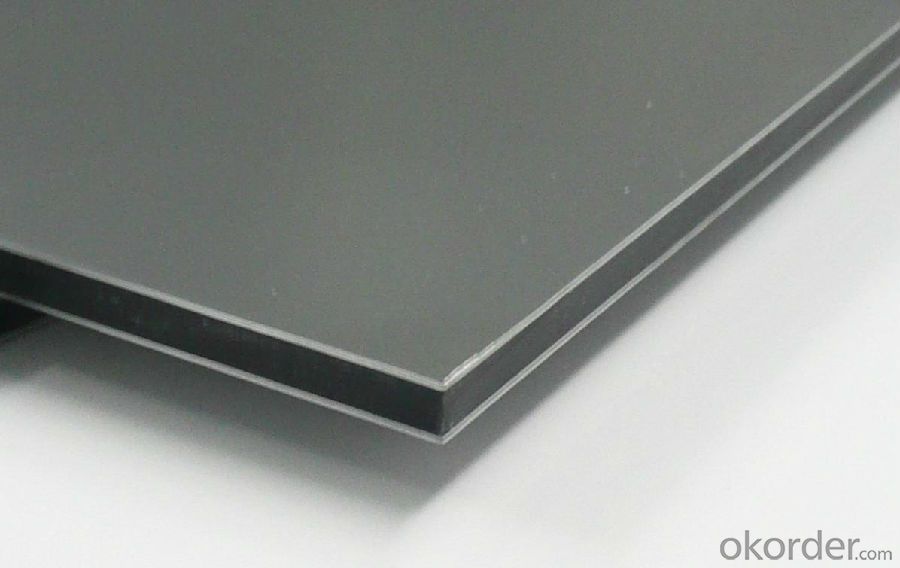

4mm thickness Aluminum Composite panel/Alucobond

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

4mm thickness Aluminum Composite panel/Alucobond

1. Standard:

according to GB/T 17748-1999 standard

2. Material:

a) Front: aluminum alloy sheet coated with fluoro-carbon resin

(PVDF) and polyester resin (PE) roasting painting

b) Core: nontoxic polyethylene.

c) Back: aluminum alloy sheet coated with polyester resin painting

d) Surface finish: treated with PVDF and PE resin rolling roasting .

coating

e) Surface coating thickness: 30um

f ) Aluminum alloy sheet thickness: 0.1mm, 0.12mm, 0.15mm, 0.2mm,

0.3mm, 0.4mm, 0.45mm, 0.5mm

3. Dimensions:

a) Thickness: 3mm, 4mm

b) Width: 1220mm 1500mm..

c) Length: 2440mm, 3200mm, 4000mm,5000mm (max: 6 meter)

d) Weight: 5.5kg/sqm based on 4mm thickness.

e) Standard size: 1220 x 2440mm

f) Nonstandard sizes are available according to requirement of customers

4. Application scope:

1) Building exterior curtain walls..

2) Decoration and renovation additions for old buildings

3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

4) Shop door decorations

5) Advertisement board display platforms and signboards

6) Wallboards and ceilings for tunnels..

7) Industrial materials, materials for vehicles and boats

Production Machinery:

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

|---|---|---|---|---|

| Coating line | WANGUAN | 2 | 4.5 | Acceptable |

| Aluminum plastic composite line | FB1600 | 4 | 3.5 | Acceptable |

| Embossing line | No information | 1 | 1.0 | Acceptable |

Testing Machinery:

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

|---|---|---|---|---|

| Bending machine | No information | 1 | 8.0 | Acceptable |

| Visual comparison of the colour device | MSBS-1 | 1 | 5.0 | Acceptable |

| Drying oven | PULUO | 1 | 5.0 | Acceptable |

- Q: Aluminum plate, aluminum veneer in the end how much the market? Expert advice.

- How are you doing that? Reply to your website I look at it?

- Q: I am not on the aluminum construction, would like to know the door of the aluminum-plastic plate construction and external construction, I hope you have educated us, first thank you

- External walls pay attention to waterproof lightning protection connection.

- Q: Saw this aluminum plate, with aluminum alloy saw blade, or grinding wheel is good?

- Aluminum alloy saw fast, slow grinding wheel

- Q: I want to open a small aluminum-plastic plate factory, how much money

- Production of aluminum-plastic board products, the need for pretreatment, painting, composite three sets of equipment, this down 800,000 on it, if it is a small factory, then you can find third-party manufacturers to paint, you can only on the composite line, so Single equipment 50 million enough.

- Q: Home decoration has several commonly used plate classification

- Particleboard by the wood chips and scraps, such as adhesive after the suppression made.

- Q: China, there is no sale of Japan is not the Department of aluminum or steel pipe

- The composition of aluminum-plastic composite plate is made of multi-layer composite material, the upper and lower layers of high-purity aluminum alloy plate, the middle of non-toxic low-density polyethylene (PE) core board, the front also paste a protective film. For outdoor, aluminum-plastic panels coated with fluorocarbon resin (PVDF) coating, for the interior, the front can be non-fluorocarbon resin coating. Features of aluminum-plastic plate Aluminum-plastic plate is easy to process, forming a good material. But also for the pursuit of efficiency, for the time of the fine products, it can shorten the duration and reduce costs. Aluminum-plastic plate can be cut, cut, slotted, band saw, drilling, processing buried head, you can also cold bending, cold fold, cold rolling, can also riveting, screw connection or glue bonding.

- Q: Aluminum veneer, aluminum-plastic plate clerk after the completion of the project, how to allow customers the shortest time remittance? What if the customer is always not remitting?

- Go to the customer home squatting

- Q: Why do you stay 0.3mm plastic when processing aluminum-plastic composite board?

- Protect the aluminum skin is not directly exposed to the air, but also in the folding time is not easy to break

- Q: By the radiator, affixed to the wall of the aluminum-plastic plate afraid of high temperature by radiator, affixed to the wall of the aluminum-plastic plate afraid of high temperature

- Hello, aluminum-plastic plate with high temperature, corrosion-resistant advantages, but a long time baking, will be relatively reduced service life. Hope can help you.

- Q: About the introduction

- Fire board, also known as fire board, or high pressure decorative panels. It is the kraft paper impregnated in the resin, after high temperature and high pressure treatment, the production of interior decoration surface materials. With wear resistance, heat resistance, impact resistance, acid and alkali resistance, smoke burning, fire, anti-bacterial, anti-mildew and anti-static characteristics. Fire board is generally used for table, desktop, wall, cabinets, office furniture, hanging cabinets and other places. Common specifications: 2135mm × 915mm, 2440mm × 915mm, 2440mm × 1220mm, thickness 0.6-1.2mm.

Send your message to us

4mm thickness Aluminum Composite panel/Alucobond

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords