0.24mm 1050 Aluminum Flat Sheets and Plates

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

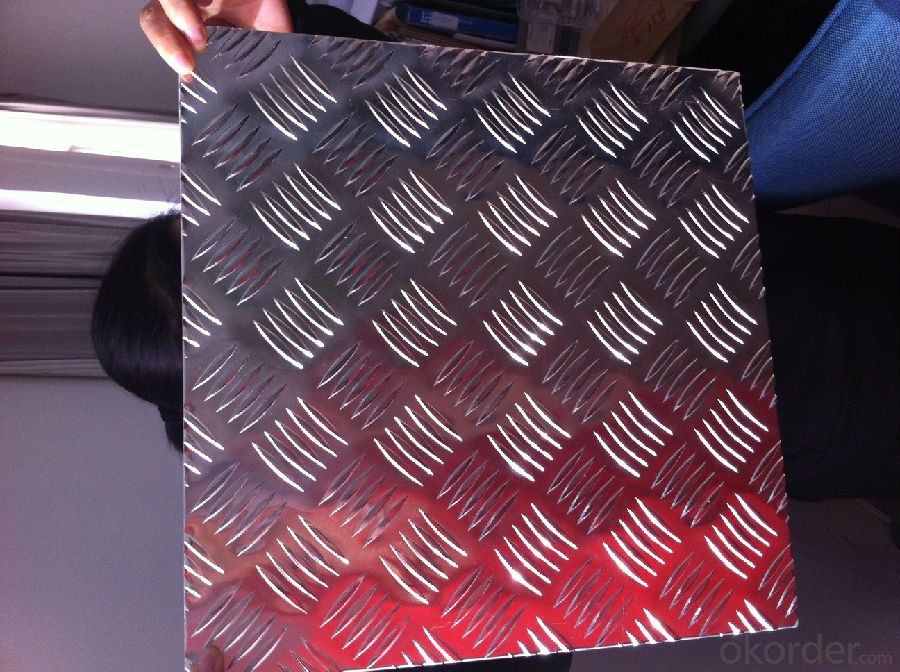

aluminum sheet, cold rolled, hot rolled, alumium coil, aluminum checkered sheet, aluminum mirror finish sheet are all our standard productions, etc.

which are widely used in the field of construction and decoration field, etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

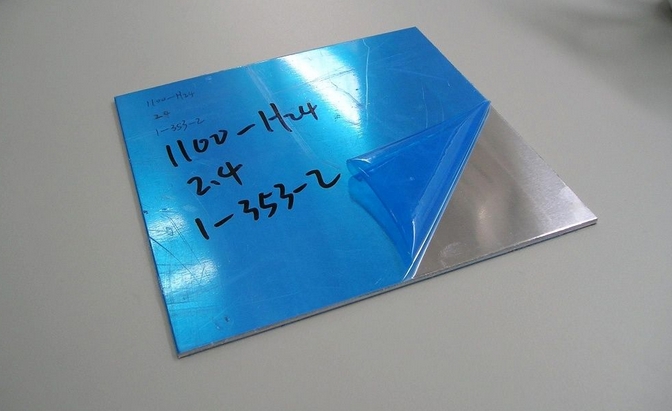

3. Image.

4. Product detailed sizes:

1000mm*2000mm,etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the length range:

---It is from 2000mm to 6000mm, etc.

what is your MOQ noramlly?

---normally it is around 5 tons/each size.

how many tons did you export in each year?

---normally it is around 8000 tons totally.

which countries did you export before?

----normlaly is is all over the world, etc.

- Q: aluminum is used to make planes, cast iron is used to make heavy mashines. what is the comparisonof teh densities of aluminum and cast iron?

- The density of aluminum is MUCH lower than cast iron (thus, aluminum is LIGHTER). Because it is lighter, it would be much more ideal for applications like plane building, which is why aluminum is used over cast iron in airplanes. As well, aluminum has a protective coating called aluminum oxide which protects it from corroding in water. [Answer: see above]

- Q: What are the different types of patterns available for aluminum sheets?

- There are several different types of patterns available for aluminum sheets, including diamond, tread, stucco, and perforated. Each pattern offers unique aesthetic and functional properties, catering to various applications and design preferences.

- Q: Explain the various types of coatings that can be applied to aluminum sheets.

- <p>Aluminum sheets can be coated with several options to enhance their appearance, durability, and functionality. These include: 1) Anodizing, which creates a protective oxide layer, 2) Powder coating, offering a wide range of colors and textures, 3) Liquid painting, for a smooth, painted finish, 4) Laminating, which bonds a protective film to the surface, 5) Electrolytic coloring, resulting in a variety of colors, 6) PVD (Physical Vapor Deposition), for a high-quality, durable finish, and 7) Thermal spraying, applying a coating to improve wear resistance. Each method serves different purposes and has its advantages and limitations.</p>

- Q: which has more volume? a kg of gold or a kg of aluminum? please explain in physics terms

- Think of it this way: Which metal is lighter? How do you know this? Because a given volume of gold weighs more than a given volume of aluminum. So which one has more volume? A kg of aluminum.

- Q: Can aluminum sheets be perforated for ventilation purposes?

- Indeed, ventilation purposes can be accomplished by perforating aluminum sheets. The process of perforating involves the creation of minute holes or designs on the sheet to facilitate the flow of air and ventilation. This method finds widespread usage in diverse industries like construction, automotive, and manufacturing. Perforated aluminum sheets provide numerous advantages for ventilation objectives, including improved air circulation, temperature regulation, and moisture management. The size, shape, and arrangement of the perforations can be tailored to meet specific ventilation needs. Furthermore, perforated aluminum sheets possess attributes such as lightness, robustness, and resistance to corrosion, rendering them highly suitable for applications that demand both ventilation and structural integrity.

- Q: What does aluminum plate "3003-H24" mean?

- (1) Hxx state:H1 * - hot rolling, Zhang Liqiang; H2 * - continuous casting and rolling, Zhang Liqiang, part of the toughening; H3 * - after stress treatment, stable performance; H4 * - after paint or coating; H x 2 - 25% x 4 - H hardness; hardness 50% processing; H * 6 - 75% hardness; H * 8 - 90 more than the hardness.(2) Hxxx state:H111: suitable for the final annealing, but also a proper amount of work hardening, but the degree of hardening is not as good as the H11 state of the product.H112: for hot forming products, the mechanical properties of the condition are specified.H116: made for magnesium content more than 4% 5 * * * alloy products. These products have specified mechanical properties and anti stripping corrosion resistance requirements.

- Q: Is it possible to use aluminum sheets as a material for flooring?

- <p>Yes, aluminum sheets can be used for flooring materials. They are known for their durability, resistance to corrosion, and ease of maintenance. Aluminum floors are often used in commercial and industrial settings due to their strength and ability to withstand heavy loads. They are also favored for their slip resistance and non-flammable properties, making them a safe choice for various applications. However, they may not be as common in residential settings due to cost and the鍐板喎 feel underfoot compared to traditional flooring materials like wood or carpet.</p>

- Q: Can 101 aluminum sheets be anodized for outdoor architectural applications?

- Yes, 101 aluminum sheets can be anodized for outdoor architectural applications. Anodizing is a process that adds a protective layer to the surface of aluminum, making it more resistant to corrosion and wear. It is commonly used for architectural applications where the aluminum needs to withstand exposure to outdoor elements. By anodizing the 101 aluminum sheets, they can be made more durable and suitable for outdoor use, ensuring that they will maintain their appearance and performance over time.

- Q: What's the price of the 6mm aluminum sheet?

- Aluminum single board, white meters, Beijing reference price of 320 yuan / square meter, specific to take into account your size, material requirements, plate type and so on, generally see drawings quote.

- Q: Are aluminum sheets suitable for storage tanks?

- Yes, aluminum sheets can be suitable for storage tanks depending on the specific requirements and purpose of the tank. Aluminum is a lightweight and corrosion-resistant material, making it an excellent choice for various storage applications. It offers good structural integrity and durability, with the ability to withstand harsh environments and weather conditions. Additionally, aluminum has a high strength-to-weight ratio, which means it can handle heavy loads while remaining relatively lightweight. However, it is important to consider the contents of the storage tank and consult with experts to ensure that aluminum is the appropriate material choice for the specific storage requirements.

Send your message to us

0.24mm 1050 Aluminum Flat Sheets and Plates

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords