Painted Aluminum Sheets 4'X10' - Embossed Aluminum Plate for Package with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Embossed Aluminium Plate for Package Description:

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above. 3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment

2.Main Features of Embossed Aluminium Plate for Package :

Low density, light in weight

Anti-corrosion

Strong

Malleable

Naturally good looking

Recyclable

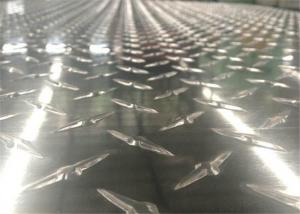

3.Embossed Aluminium Plate for Package Images:

4. Embossed Aluminium Plate for Package Specification:

| Grade | Temper | Plate Thickness (mm) | Bar Thickness (mm) | Width (mm) | Length (mm) | Surface |

| 1050 1060 1100 3003 3004 3105 5052 5005 5754 5083 6061 6063 | 0,H12, H14,H16 H18,H24H24,H26 H32,H34 | 0.8-12 | 0.1~5 | 10~1200 | 1000-10000 | PE / PVDF |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Can aluminum sheet be used for heat exchangers?

- Indeed, aluminum sheet can be effectively utilized in heat exchangers. The utilization of aluminum as a material for heat exchangers is widespread owing to its remarkable thermal conductivity, lightweight nature, and resistance to corrosion. The remarkable thermal conductivity of aluminum facilitates the efficient transfer of heat between fluids, rendering it suitable for a multitude of heat exchange applications. Furthermore, aluminum is obtainable in diverse alloys and thicknesses, granting adaptability in design and customization to cater to specific heat exchanger prerequisites. On the whole, aluminum sheet emerges as a favored option for heat exchangers in industries encompassing automotive, HVAC, and aerospace.

- Q: Im wondering as to how i darken the slide and frame of an airsoft 1911 pistol. I polished off all the black paint and exposed the chromish aluminum. I have some ideas to darken the metal but not sure. Maybe using olive oil and heating it up but im afraid i might warp the metal. I want it to come out sort of like a greyish gunmetal. Anybody know of a good process to give that worn out war like effect to the gun without painting it?

- Use gun bluing . It is the stuff they use on steel guns, it is kind of a dye. Got at a sports store that sells real guns.

- Q: Explain the distinction between aluminum sheets based on their thickness.

- <p>Aluminum sheets with different thicknesses primarily differ in their strength, weight, and applications. Thicker sheets offer greater strength and rigidity, making them suitable for structural applications or heavy-duty uses. In contrast, thinner sheets are lighter and more flexible, ideal for applications requiring formability or where weight is a concern, such as in the automotive or aerospace industries. The choice of thickness depends on the specific requirements of the project, including load-bearing needs, durability, and aesthetic considerations.</p>

- Q: Can 101 aluminum sheets be used for roofing or siding?

- Indeed, one can utilize 101 aluminum sheets for either roofing or siding purposes. Aluminum, renowned for its robustness, lightweight composition, and ability to resist corrosion, remains a favored material for both roofing and siding applications. Opting for aluminum sheets as a roofing or siding solution guarantees a durable outcome, capable of enduring adverse weather conditions with minimum upkeep. What's more, aluminum sheets are accessible in several thickness options, including 101, thereby providing flexibility to accommodate diverse design and structural requirements.

- Q: Are aluminum sheets suitable for signage?

- Yes, aluminum sheets are highly suitable for signage. Aluminum is a versatile material that offers a range of benefits for signage applications. It is lightweight, durable, and resistant to corrosion, making it ideal for both indoor and outdoor signage. Aluminum sheets can withstand harsh weather conditions, including rain, snow, and UV exposure, without deteriorating or fading. They are also easy to work with, allowing for a variety of customization options such as embossing, engraving, and digital printing. Moreover, aluminum sheets are cost-effective and have a long lifespan, ensuring that signage remains in excellent condition for extended periods. Overall, aluminum sheets are a popular choice for signage due to their durability, versatility, and aesthetic appeal.

- Q: has aluminum sheet reacted with concentrated sulfuric acid?

- it can be regarded as no reaction, concentrated sulfuric acid will make aluminum's surface inactivation,and produce a layer of dense aluminium oxide film which will prevent further reaction.

- Q: Are the aluminum sheets suitable for manufacturing window frames?

- Certainly, aluminum sheets are an ideal option when it comes to crafting window frames. Aluminum has gained widespread popularity as a material for window frames owing to its numerous beneficial characteristics. Notably, aluminum is both lightweight and sturdy, facilitating effortless installation and effectively combating corrosion. Moreover, aluminum boasts exceptional malleability, enabling diverse design opportunities and personalized modifications. Furthermore, aluminum window frames exhibit commendable thermal efficiency, exceptional noise attenuation, and demand minimal upkeep. Consequently, aluminum sheets emerge as a fitting and dependable choice for producing top-notch window frames.

- Q: Is it possible to use aluminum sheets in extreme weather conditions, including very hot and very cold temperatures?

- <p>Yes, aluminum sheets can be used in harsh environments, including hot and cold climates. Aluminum is known for its excellent corrosion resistance and durability, making it suitable for various weather conditions. It does not rust and maintains its strength in both low and high temperatures. However, it's important to consider the specific alloy and protective coatings used, as these can affect performance in extreme conditions. Properly treated and coated aluminum can withstand significant temperature fluctuations without significant degradation.</p>

- Q: Is it possible to incorporate recycled aluminum windows into a construction or renovation project?

- <p>Yes, you can use recycled aluminum windows in your project. Recycled aluminum windows are not only environmentally friendly but also offer similar performance to new aluminum windows. They are durable, lightweight, and maintain good thermal efficiency. When selecting recycled aluminum windows, ensure they meet the required quality standards and are suitable for your project's specifications. It's also important to consider the condition of the windows and any necessary refurbishment or maintenance they might require.</p>

- Q: have been taking an over the counter Antacid consistently for the past 8 years as a daily source of extra calcium per the bottle. Now, I am getting many nerve problems, similar to Lou Gehrig's disease. I am a healthy 38 year old male who excersises, eats right and is generally health conscious. I am concerned that unknowingly I have toxified my body with the aluminum that apparently is in Antacid. I did not know this until now or of course I would not have gone any where near it.Can taking Antacid lead to nerve problems such as Lou Gehrig's disease?

- Aluminum okorder /

Send your message to us

Painted Aluminum Sheets 4'X10' - Embossed Aluminum Plate for Package with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords