1 Inch Wide Aluminum Alu Strips

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

specifications:01) alloy: a3003 a110002) aluminium thickness: 0.026mm -

0.60mm03) aluminium width:a) standard width: 1,240mmb) special width:

1,300mm, 1,520mm, 1,570mm and 1,595mm are also available04) coating finish:

pvdf, polyester, acrylic05) total coating thickness:a) pvdf coating: more than

25 micronb) polyester coating: more than 18 micron06) coating hardness (pencil

hardness) more than 2h07) adhesion: 5j08) impact resistance: no cracking and

peeling09) flexibility (t-bend): 2t10) mek resistance: more than 10011) bottom

side aluminium sheet is coated with protective polyester material, an the

thickness is more than 6 micron12) minimum order: 1mt/1 x 20' fcl (about

17mt)13) certification: certificate of origin14) delivery time: 8 - 15 days after

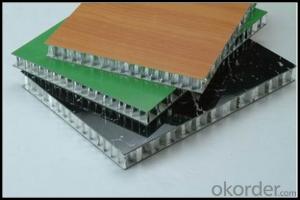

receiving your first depositapplications:used to manufacture decorative

materials, such as aluminium composite panels, brushed panels, lampshades,

and other composite panels:1) exterior applications: wall cladding, facades,

roofs and canopies, tunnels, column covers or renovations2) interior

applications: wall cladding, ceilings, bathrooms, kitchens and balconies3)

advertisement and market applications: display platformssignboards, fascias

and shop fronts4) transport and industrial applicationspacking:export standard,

wooden splint

- Q: Is it possible to utilize aluminum strips for creating signs or banners?

- <p>Yes, you can use aluminum strips to make signs or banners. Aluminum is lightweight, durable, and resistant to weather, making it a popular choice for outdoor signage. It can be cut, bent, and shaped easily to create various designs. Additionally, aluminum strips can be painted or printed on, allowing for customization with text and graphics. However, ensure that the aluminum is of the appropriate thickness and quality for your specific project to maintain its structural integrity and longevity.</p>

- Q: What benefits can be gained from incorporating aluminum strips in construction projects?

- <p>Aluminum strips offer several advantages in construction, including high strength-to-weight ratio, which means they are strong yet lightweight. They are also resistant to corrosion, making them suitable for outdoor applications and harsh environments. Aluminum strips are easy to work with, allowing for easy installation and customization. They are also energy-efficient, as they reflect heat and can help reduce cooling costs. Additionally, aluminum is recyclable, contributing to sustainability and reducing waste.</p>

- Q: What types of aluminum strips are known for their durability and longevity?

- <p>Yes, there are several types of aluminum strips known for their durability and longevity. These include 3003-H14, 5052-H32, and 6061-T6 aluminum alloys. 3003-H14 is known for its excellent corrosion resistance and formability, making it ideal for applications requiring high durability. 5052-H32 offers good strength, corrosion resistance, and weldability, suitable for marine and structural applications. 6061-T6 is valued for its high strength-to-weight ratio and is commonly used in aerospace and automotive industries where long-lasting performance is crucial. Proper surface treatments and coatings can further enhance the durability and longevity of aluminum strips.</p>

- Q: What specific tools or equipment are necessary to install aluminum strips?

- <p>To install aluminum strips, you generally need a few basic tools. A measuring tape is essential for accurate placement. A utility knife or a metal cutting tool is necessary for cutting the strips to the correct length. A level is crucial to ensure the strips are straight. A rubber mallet or a hammer can be used to secure the strips in place. Adhesive, such as construction adhesive or double-sided tape, is often required to attach the strips. Safety equipment like gloves and safety goggles should be worn to protect against sharp edges and debris.</p>

- Q: What are the environmentally friendly options for aluminum strips?

- <p>Yes, there are environmentally friendly types of aluminum strips. Recycled aluminum strips are more eco-friendly as they require significantly less energy to produce compared to virgin aluminum. Additionally, using aluminum strips with a high recycled content reduces waste and conserves natural resources. Another option is to look for aluminum strips that are produced using renewable energy sources, which further reduces their carbon footprint. Lastly, choosing aluminum strips with a lower coating or treatment that is biodegradable or has a lower environmental impact can also contribute to their environmental friendliness.</p>

- Q: What is the difference between cold rolling and hot rolling of aluminium plate and aluminium strip? Which kind of aluminum plate is good? Speak a little more popularly

- Cold rolled, no hot rolled aluminum sheet, good surface. It doesn't make much difference if you don't ask for it. Hot rolled aluminum plate is suitable for oxidation. The oxidation effect will be much better.

- Q: Can metal roofing materials be reused or recycled after they have been installed and used?

- <p>Yes, metal roofing materials can indeed be recycled after installation. Metal is one of the most recycled materials globally, and its recycling process is both efficient and environmentally friendly. When metal roofing reaches the end of its life, it can be collected, processed, and turned into new metal products, including new roofing materials. This recycling process helps conserve natural resources and reduces waste in landfills. The high recycled content of metal can also contribute to the sustainability and green credentials of construction projects.</p>

- Q: Is it possible to apply paint to aluminum strips once they have been installed?

- <p>Yes, aluminum strips can be painted after installation. However, it is essential to prepare the surface properly. This includes cleaning the aluminum to remove any dirt or grease, then lightly sanding it to create a better surface for the paint to adhere to. It is also recommended to use a primer specifically designed for metal surfaces to enhance the paint's durability and adhesion. After priming, the aluminum strips can be painted with a suitable paint, such as a high-quality acrylic or enamel paint, following the manufacturer's instructions for application and drying times.</p>

- Q: How can the aluminium band be welded to the steel shell?

- Aluminum strip can be welded to the steel shell, mainly to see the aluminum strip thickness, to select the welding method and welding materials according to thickness.

- Q: What characteristics of aluminum strips make them an ideal material for roofing purposes?

- <p>Aluminum strips are suitable for roofing due to their lightweight nature, which reduces structural load. They offer excellent corrosion resistance, protecting against rust and decay, and are highly durable, maintaining their integrity for decades. Aluminum's malleability allows for easy shaping into various profiles, enhancing design flexibility. Additionally, aluminum strips reflect heat well, reducing energy consumption for cooling, and they are recyclable, contributing to environmental sustainability.</p>

Send your message to us

1 Inch Wide Aluminum Alu Strips

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords