1 4 Inch Aluminum Sheets D.C 1xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Sheets D.C 1XXX Description

Aluminum Sheets D.C 1XXX is cut from aluminum coils 1xxx. The aluminum content of Aluminum Sheets D.C 1XXX is 99% at least. It has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum Sheets D.C 1XXX is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of the Aluminum Sheets D.C 1XXX

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

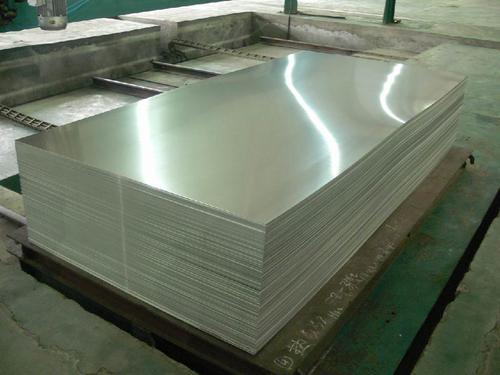

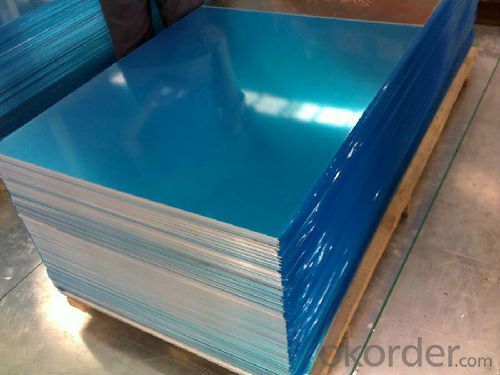

3.Aluminum Sheets D.C 1XXX Images

4.Aluminum Sheets D.C 1XXX Specification

| Alloy | AA1xxx (AA1050,AA1060,AA1070,AA1100 etc |

| Tmeper | H14, H16, H18, H22, H24, H26, H32, O/F |

| Thickness | 0.2mm-100mm |

| Width | 30mm-1700mm |

| Standard | GB/T 3880-2006 |

5. FAQ of Aluminum Sheets D.C 1XXX

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test the Aluminum Sheets D.C 1XXX products.

B. Now which countries do you export your goods?

Now we export to South East Asia,Africa, North America,South America ect.

- Q: This question asks for methods to preserve the aesthetic quality of aluminum sheets and prevent deterioration over time.

- <p>To maintain the appearance of aluminum sheets over time, follow these steps: 1. Regularly clean the sheets with a mild detergent and water to remove dirt and grime. 2. Avoid using harsh chemicals or abrasive materials that can scratch the surface. 3. Apply a protective coating or sealant if the sheets are exposed to harsh weather conditions or corrosive environments. 4. Inspect the sheets periodically for signs of corrosion or damage and address any issues promptly. 5. Keep the aluminum sheets dry, as moisture can lead to rust and other forms of deterioration. Proper maintenance will help preserve the appearance and longevity of aluminum sheets.</p>

- Q: How would you write the formula for aluminum sulfate and calcium chloride?

- Aluminium sulfate: Molecular formula Al2(SO4)3·16H2O Calcium chloride: Molecular formula CaCl2

- Q: What does everyone think about replacing aluminum bats with wooded ones in high school. More and more cities are going back to wood.........why

- I don't have any particular beef against aluminum bats, but I also don't think they add anything to the game. If wooden bats are safer, then go with them, I say.

- Q: What are the different methods of surface treatment for aluminum sheets?

- Some of the different methods of surface treatment for aluminum sheets include anodizing, powder coating, painting, polishing, and brushing.

- Q: Hey I just noticed that my deodorant/antiperspirant has aluminum in it. I remember reading that this is bad for you. My question is, will this be dangerous for my health in the long run?

- Yes. Use natural.

- Q: This question asks for an explanation of the various types of coatings applied to aluminum sheets that are used outdoors.

- <p>Aluminum sheets used for exterior applications are often coated to enhance their durability, weather resistance, and aesthetic appeal. The different types of coatings include: 1. Anodizing, which creates a protective oxide layer on the aluminum surface. 2. Powder coating, a dry finishing process that provides a uniform and durable finish. 3. PVDF (Polyvinylidene Fluoride) coating, known for its excellent resistance to UV rays and chemicals. 4. Fluorocarbon coatings, which offer superior resistance to weathering and color retention. 5. Electrolytic coating, which involves the application of a thin protective layer through an electrochemical process. Each coating type has specific properties that make it suitable for different exterior applications and environmental conditions.</p>

- Q: I saw a nice looking set of cast aluminum pots for a very good price. They feel very heavy. But I remember hearing that aluminum is not healthy so I am wary of buying them. Any advice would be appreciated.

- The cast aluminium pot are used in families, hotels and for any needs. They are very safe to cook.

- Q: What are the different types of aluminum sheets available?

- There are several different types of aluminum sheets available, each with their own unique properties and uses. Some of the most common types include: 1. Pure Aluminum Sheets: These sheets are made from 100% aluminum and are known for their excellent corrosion resistance and high thermal conductivity. They are often used in applications where lightweight and durability are important, such as in the aerospace industry. 2. Aluminum Alloy Sheets: These sheets are made by combining aluminum with other elements, such as magnesium, copper, or zinc, to enhance specific properties. For example, aluminum-magnesium alloy sheets (5000 series) are known for their excellent strength and resistance to corrosion, making them suitable for marine applications. 3. Painted Aluminum Sheets: These sheets have a layer of paint or coating applied to their surface, providing them with additional protection against corrosion and enhancing their aesthetic appeal. They are commonly used in architectural projects and signage. 4. Perforated Aluminum Sheets: These sheets have small holes or perforations evenly spaced across their surface. They are often used in applications where airflow or visibility is required, such as in HVAC systems, decorative panels, or speaker grilles. 5. Embossed Aluminum Sheets: These sheets have a raised pattern or design on their surface, achieved through a process of embossing. This not only adds visual interest but also increases the strength of the sheet, making it suitable for applications such as flooring, vehicle panels, or decorative purposes. 6. Anodized Aluminum Sheets: This type of aluminum sheet undergoes an electrolytic process called anodizing, which forms a protective layer on its surface. Anodized sheets are highly resistant to corrosion and wear, making them ideal for outdoor applications, such as building facades, window frames, or automotive trim. It is important to consider the specific requirements of your project before selecting the type of aluminum sheet. Factors such as strength, corrosion resistance, appearance, and cost should be taken into account to ensure the right sheet is chosen for the job.

- Q: Can the aluminum sheets be used for manufacturing aircraft landing gears?

- Indeed, the utilization of aluminum sheets is viable for the production of aircraft landing gears. Aluminum stands as a widely chosen substance within the aerospace field due to its beneficial attributes, namely its lightweight yet robust composition, exceptional resistance against corrosion, and commendable fatigue performance. These characteristics render aluminum sheets apt for the manufacturing of diverse aircraft components, including landing gears. The integration of aluminum into landing gears plays a pivotal role in diminishing the overall weight of the aircraft, a crucial aspect for optimizing fuel efficiency and overall performance. Moreover, aluminum boasts the capability to be effortlessly shaped, welded, and machined, thereby facilitating the creation of intricate forms and designs indispensable for landing gears.

- Q: Are aluminum sheets suitable for high-temperature applications?

- No, aluminum sheets are not suitable for high-temperature applications as they have a low melting point and tend to lose their strength and become deformed at high temperatures.

Send your message to us

1 4 Inch Aluminum Sheets D.C 1xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords