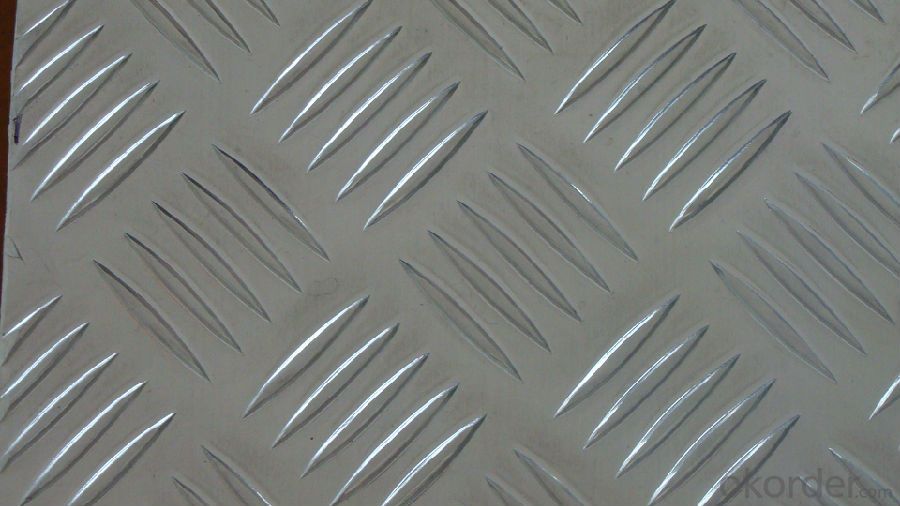

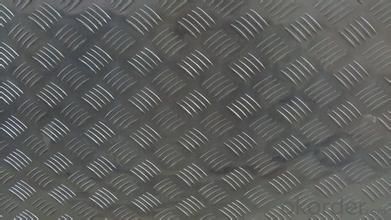

Weight of Diamond Aluminum Plate Color Anodized Aluminum Sheet Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Discription:

Aluminum Sheets

Alloy No.: 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3104, 3105, 5005, 5052, 5083, 5754, 8011, 8006, 8079, etc..

Temper: H14, H16, H18, H22, H24, H26, H32, O/F

Thickness: 0.2mm-20mm

Width: 10mm - 2100mm

1.Dark green surface, color changed into light green after exposure.Image checked easily.

2.Surface Quality :be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

3.Faithful reproduction capacity, result at clear images.

4.Highly durable, long impression available.

5.Excellent sensitive character.

6.Resolution : 2%-98%

7.Material:1050/1060/1070/1100/2A16/2A06/2A12/2024/3003/3A21/4A01/5052/5005/5083/5A05/6061-T6/6063-T5/6082/7021/7075-T6/8011,etc

8.Certificate: ISO9001:2000, SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO)

9.Packing:First, plastic cloth; Second, Pearl Wool ; Third, wooden cases with dry agent ,without fumigation,wooden pallets

10.Application:Aircraft, automobile, train,Building wall, ceilings, roofing, furniture cabinet, lighting plate,etc

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q: AND WAT R THE THECNOLOGICAL ANDCOSTS AND BENEFITESOF USING ALUMINUM? what health -related and environment-related issues gave surface as aresult of its widespread use in society?

- airplanes are made from aluminum. certain beverages are also. aluminum is cheaper and lighter. the biggest problem is the amount of electricity that it takes to make aluminum

- Q: Is it possible to utilize aluminum sheets for creating signs or banners?

- <p>Yes, you can use aluminum sheets to make signs or banners. Aluminum is a popular choice due to its durability, lightweight, and resistance to weather conditions. It can be easily cut, shaped, and printed on, making it ideal for outdoor signage. Additionally, aluminum sheets can be coated or laminated to enhance their visual appeal and protect against scratches and fading.</p>

- Q: What are the applications of aluminum sheets?

- Aluminum sheets have a wide range of applications across various industries. They are commonly used in the construction industry for roofing, siding, and cladding due to their lightweight, durability, and corrosion resistance. Aluminum sheets are also utilized in the automotive industry for body panels and structural components, as well as in the aerospace industry for aircraft parts. Additionally, they are commonly found in the manufacturing of household appliances, packaging materials, and electrical equipment.

- Q: What are the advantages of using aluminum sheets in the transportation industry?

- There are several advantages of using aluminum sheets in the transportation industry. Firstly, aluminum is a lightweight material, making it ideal for use in vehicles as it helps reduce fuel consumption and increase overall efficiency. This is particularly important for industries such as aviation and automotive, where weight reduction is a key factor in improving performance. Secondly, aluminum has excellent corrosion resistance properties. This is crucial in the transportation industry, where vehicles are exposed to various environmental conditions such as rain, snow, and road salt. Using aluminum sheets helps to extend the lifespan of vehicles and reduces maintenance costs associated with corrosion-related issues. Additionally, aluminum is highly recyclable, making it a more sustainable choice compared to other materials. The transportation industry is increasingly focusing on sustainability, and the use of aluminum sheets aligns with these goals. Recycling aluminum requires significantly less energy compared to producing it from raw materials, leading to reduced carbon emissions and energy consumption. Moreover, aluminum offers excellent formability and versatility. It can be easily molded into various shapes and sizes, allowing manufacturers to design lightweight yet strong structures. This flexibility in design enables the production of more aerodynamic vehicles, leading to improved fuel efficiency. Lastly, aluminum sheets have high strength-to-weight ratio, meaning they can provide the required strength while still being lightweight. This property makes aluminum an ideal material for applications that require strength and durability, such as vehicle bodies, chassis, and structural components. Overall, the advantages of using aluminum sheets in the transportation industry include weight reduction, corrosion resistance, sustainability, formability, versatility, and high strength-to-weight ratio. These benefits contribute to improved performance, fuel efficiency, and durability of vehicles, making aluminum an excellent choice for various transportation applications.

- Q: The difference between aluminum plate and aluminum plate

- Aluminum plate is a large piece, the regular width is 90 to 130 centimeters. The aluminum plate is cut aluminum plate, usually according to requirements made several centimeters wide.

- Q: Can aluminum sheets be used for pharmaceutical lab equipment?

- Yes, aluminum sheets can be used for pharmaceutical lab equipment. Aluminum is a commonly used material in the pharmaceutical industry due to its non-toxicity, corrosion resistance, and ease of sterilization. It is often utilized for constructing lab equipment like trays, containers, and shelves.

- Q: What does aluminum plate "3003-H24" mean?

- 3003 refers to manganese as the main alloying elements of aluminum alloy"H24" is a condition in which aluminum alloys increase their strength by working hardening

- Q: Can aluminum sheets be used for outdoor furniture?

- Indeed, outdoor furniture can certainly make good use of aluminum sheets. Due to its durability, lightweight properties, and ability to resist rust and corrosion, aluminum is widely favored for outdoor furniture. It can endure diverse weather conditions, making it highly suitable for outdoor applications. Moreover, aluminum can be effortlessly molded and shaped into various designs, providing a vast array of furniture styles. By utilizing aluminum sheets in outdoor furniture, one ensures long-lasting quality and aesthetic charm, rendering it a pragmatic and adaptable option for outdoor settings.

- Q: Can aluminum sheets be used for chemical reactors?

- Yes, aluminum sheets can be used for chemical reactors in certain applications. Aluminum is known for its excellent corrosion resistance, which makes it suitable for various chemical reactions. However, it is important to consider the type of chemicals being used and their potential reactivity with aluminum. Aluminum may not be suitable for highly acidic or alkaline environments as it can react and corrode. Additionally, aluminum may not be appropriate for reactions involving certain gases or high temperatures. In such cases, alternative materials like stainless steel or glass-lined reactors may be more suitable.

- Q: Can the aluminum sheets be custom-cut to specific dimensions?

- Indeed, it is possible to have aluminum sheets custom-cut to specific dimensions. Aluminum, being a material of great versatility, can be easily manipulated to achieve precise cuts that meet particular requirements. Whether for industrial, commercial, or personal purposes, aluminum sheets can be tailored to the exact dimensions desired, guaranteeing a flawless fit for any undertaking. This option for customization offers enhanced flexibility, enabling the aluminum sheets to be utilized in a multitude of applications.

Send your message to us

Weight of Diamond Aluminum Plate Color Anodized Aluminum Sheet Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords