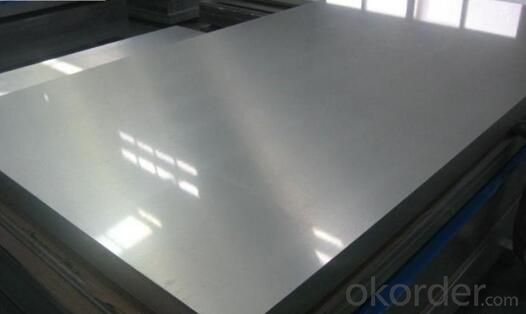

Aluminum Sheets 1/16 4'X8 Prices - 5052 5086 Alloy 2mm 3mm 4mm Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum Sheet for Making Aluminum Composite Panel

Aluminum sheet specifications:

1) Alloy : 1050 1060 1070 1100 2024 3003 3004 3105 3A21 5005 5052 5083 5754 5182 5454 5456 6061 6063 7075 8011 etc

2) Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.1mm to 300mm

4) Width:20mm to 3300mm

5)Length: ≤ 12000mm

6) Protective film can be added

7) Production Line: DC and CC production line

Discription:

Width: 50-800mm

Thickness: 8-25mic

Length: 3-300m

Character:

High-temperature sterilization

Made of advanced food grade alu material,no pollution

Eco-friendly, recoverable and recyclable

Application:

widely used for food cooking, freezing wrapping, storing etc, the main application are for household and catering, which are targeting for retail market and food service market, such as hypermarket, chain store and hotel, restaurant etc.

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q: Are the aluminum sheets suitable for manufacturing architectural roof systems?

- Yes, aluminum sheets are suitable for manufacturing architectural roof systems. Aluminum is a popular choice for roofing materials due to its durability, lightweight nature, and resistance to corrosion. These qualities make it ideal for withstanding various weather conditions, including high winds, rain, and snow. Additionally, aluminum can be easily fabricated and shaped into different forms, allowing for flexibility in design and installation. It is also a sustainable and environmentally friendly option as it can be recycled. Overall, the use of aluminum sheets in manufacturing architectural roof systems offers numerous benefits and is a suitable choice for this application.

- Q: What is the best way to paint over aluminium siding? Should it be primed? What type of prime should be used? What type of paint should be used on this surface? What brush or roller should be used to apply the paint?

- while I've never done it, my brother in law painted their aluminum siding. He used paint he bought at sears- go to a paint store, one that only sells paint and pick their brains. He power washed the house, primed it and used a sprayer to apply both the paint and the primer....the house looks like they replaced the siding.

- Q: What are the different forms of aluminum sheet available?

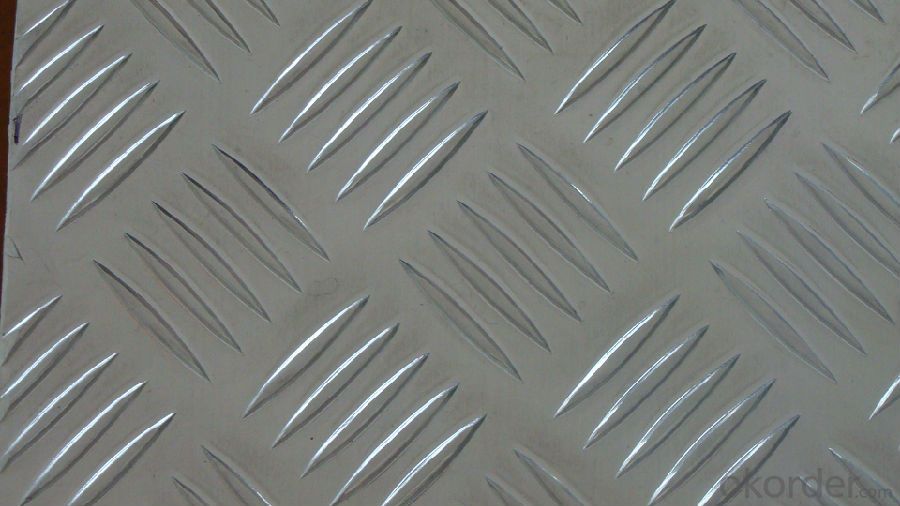

- There are several different forms of aluminum sheet available on the market. These include: 1. Plain Aluminum Sheet: This is the most basic form of aluminum sheet, without any additional finishes or coatings. It is commonly used for general applications where appearance is not a major concern. 2. Painted Aluminum Sheet: This type of aluminum sheet is coated with a layer of paint or resin, which provides additional protection against corrosion and enhances the appearance of the sheet. It is often used for decorative purposes or in applications where aesthetics are important. 3. Anodized Aluminum Sheet: Anodizing is an electrochemical process that creates a durable and corrosion-resistant surface on the aluminum sheet. Anodized sheets have a uniform finish and are available in various colors. They are commonly used in architectural applications, such as building facades or interior design elements. 4. Perforated Aluminum Sheet: This type of aluminum sheet has small holes or perforations throughout its surface. It is often used in applications where ventilation, filtration, or aesthetics are important, such as in decorative screens, speaker grills, or air diffusers. 5. Embossed Aluminum Sheet: Embossing is a process that creates raised patterns or textures on the surface of the aluminum sheet. It adds visual interest and can also improve the sheet's strength and rigidity. Embossed aluminum sheets are commonly used in architectural or decorative applications. 6. Clad Aluminum Sheet: Cladding involves bonding a layer of aluminum to another material, such as stainless steel or copper, to combine their properties. Clad aluminum sheets are used in applications where the benefits of both materials are required, such as in the construction of heat exchangers or cookware. These are just a few examples of the different forms of aluminum sheet available. Each type offers unique properties and characteristics, making them suitable for various applications in industries such as construction, automotive, aerospace, and more.

- Q: Can aluminum sheet be used for heat shielding?

- Indeed, heat shielding can be achieved by utilizing aluminum sheet. Due to its high thermal conductivity and exceptional heat dissipation characteristics, aluminum proves to be a proficient substance for applications pertaining to heat shielding. Furthermore, its capacity to reflect radiant heat renders it appropriate for deployment in thermal barriers and insulation systems. Moreover, the lightweight nature, resistance to corrosion, and ease of fabrication associated with aluminum sheet render it an economical option for heat shielding across diverse industries including aerospace, automotive, and electronics.

- Q: Are aluminum sheets suitable for signage applications?

- Indeed, signage applications can benefit from the use of aluminum sheets. Due to its lightweight nature and durability, aluminum proves to be an ideal material for outdoor signs that must endure diverse weather conditions. Its resistance to rust and corrosion guarantees the sign's longevity. Moreover, aluminum sheets can be effortlessly customized and shaped into various sizes, enabling the creation of versatile and imaginative signage options. Furthermore, aluminum serves as an exceptional material for digital printing, producing top-notch graphics and images. All in all, aluminum sheets present remarkable durability, versatility, and aesthetic allure, cementing their status as a favored choice for signage applications.

- Q: 8mm which type of aluminum plate is suitable for bending?

- Specific recommendations were then determined by 6061, 2024, 7075 if the hardness is too high, especially for the T6 state is more, should not bend, unless you're heating and folding the difference between aluminum and aluminum is poor oxidation resistance, tolerance, surface effect, crystal accuracy and the uniform stability of a difference, not only the bending effect difference.

- Q: What is the electrical conductivity of 101 aluminum sheets?

- The electrical conductivity of 101 aluminum sheets is high due to aluminum being a good conductor of electricity.

- Q: Can aluminum sheets be used in the aerospace industry?

- Indeed, the aerospace industry does employ aluminum sheets. Aluminum, being a lightweight material with a remarkable strength-to-weight ratio, is highly favored for numerous aerospace purposes. Its usage is prevalent in the manufacturing of aircraft structures, including fuselages, wings, and panels. The adoption of aluminum sheets in the aerospace sector offers several advantages, encompassing diminished fuel consumption due to weight reduction, enhanced maneuverability, and heightened payload capacity. Furthermore, aluminum showcases excellent resistance to corrosion, a vital trait for aircraft operating in harsh environmental conditions. All in all, the aerospace industry extensively relies on aluminum sheets, owing to their advantageous properties and exceptional performance.

- Q: Can aluminum sheets be used for flooring?

- Indeed, flooring can utilize aluminum sheets. Lightweight and sturdy, aluminum proves resistant to corrosion, rendering it an appropriate option for a range of flooring uses. Notably, aluminum sheets frequently find employment in industrial, commercial, and residential settings, encompassing warehouses, garages, kitchens, and outdoor areas. These sheets offer commendable strength, effortless installation, and minimal upkeep. Furthermore, aluminum flooring imparts a polished and contemporary aesthetic to any given space. Nevertheless, prudent consideration of factors like thickness, finish, and the unique demands of the flooring project becomes imperative prior to settling on aluminum sheets.

- Q: Can the aluminum sheets be used for manufacturing aircraft landing gears?

- Yes, aluminum sheets can be used for manufacturing aircraft landing gears. Aluminum is a commonly used material in the aerospace industry due to its favorable properties, such as lightweight yet strong structure, high corrosion resistance, and good fatigue behavior. These qualities make aluminum sheets suitable for manufacturing various components of an aircraft, including landing gears. The use of aluminum in landing gears helps reduce the overall weight of the aircraft, which is crucial for fuel efficiency and performance. Additionally, aluminum can be easily formed, welded, and machined, allowing for the production of complex shapes and designs required for landing gears.

Send your message to us

Aluminum Sheets 1/16 4'X8 Prices - 5052 5086 Alloy 2mm 3mm 4mm Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords