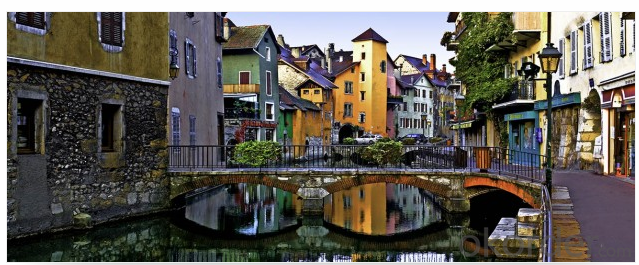

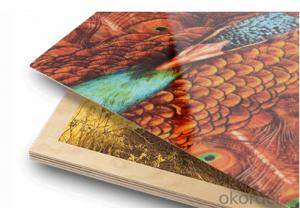

2016 HD Aluminium Metal Art Pictures Print on 4 By 8 Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 carton

- Supply Capability:

- 20000 carton/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description:

These Aluminum Panels can provide for many sizes and different color. It can suitable in many occasion, like company logo screen, show backdrop, home use, some gift use etc. We can also provide the heat press machine for transferring.

Features:

1. Extremely durable scratch resistant surface that is waterproof and can be cleaned easily with a damp cloth.

2. Eco-friendly & Terrific as a decoration.

3. Longest lasting photo medium in the current market.

4. The high definition, vibrant colors coupled with superior fade, moisture, stain & scratch resistant properties.

5. The image is infused into the coating to provide permanent protection and durability.

6. Excellent choice for commercial, fine art, and home decoration applications.

Making Process:

1. Get images from digital camera, memory card or scanner.

2. Print image with heat transfer paper and sublimation ink.

3. Lay down a teflon sheet and your panel, and another CLEAN teflon sheet on top, pre-press for 60 sec., 180℃, 0.3Mpa.

4. 60 seconds later. Wait the panel to cool.

5. Tape the transfer to the face of the substrate with heat resistent tape running parallel to the edge of the substrate.

6. Lay substrate face up, transfer on top on a piece of telfon sheet on lower platen.

7. Cover with one layer of fabric, preferably 100% polyester or poly-silk, to distribute pressure and reduce stress on the coating.

8. Press for the prescribed time is 130sec., temperature is 180℃ and pressure is 0.3Mpa.

9. When finished, remove the fabric and gently peel the taped transfer off the substrate without allowing it to slide or move.

10. Let the substrate to cool. Do not handle it until cool to reduce the chances of damaging the coating on the edges.

11. Enjoy your personal designed aluminum board!

- Q: What are the safety precautions when working with aluminum sheets?

- When working with aluminum sheets, it is important to take certain safety precautions to ensure your well-being. Here are some key safety measures to follow: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE, such as safety goggles, gloves, and a face mask, to protect yourself from potential hazards. Aluminum sheets may produce sharp edges, metal filings, or dust particles that can cause injury if they come into contact with your eyes, skin, or respiratory system. 2. Ventilation: Ensure that the work area is well-ventilated to minimize the buildup of aluminum dust or fumes. Proper ventilation helps in preventing the inhalation of harmful airborne particles, especially when cutting or shaping aluminum sheets. 3. Handling and storage: Handle aluminum sheets with care to avoid injuries. They can have sharp edges, so it is essential to wear gloves while handling them. Additionally, store the sheets in a secure and organized manner to prevent accidents like tripping or falling. 4. Cutting and shaping: When cutting or shaping aluminum sheets, use appropriate tools designed for this purpose. Avoid using tools that are not suited for aluminum, as they may cause damage or create unsafe conditions. Ensure that the cutting area is clear of clutter, and be mindful of your body position to avoid accidents. 5. Fire safety: Aluminum is a highly flammable material, so it is crucial to be cautious of fire hazards. Keep flammable materials away from the work area, and avoid using open flames or sparks in the vicinity. In case of a fire, have a fire extinguisher readily available and know how to use it effectively. 6. Training and knowledge: It is important to have proper training and knowledge about working with aluminum sheets. Understanding the properties of aluminum, the appropriate techniques, and safety precautions can help prevent accidents and injuries. 7. Regular maintenance: Keep your tools and equipment in good working condition. Regularly inspect them for any damage or wear and tear, and replace or repair as necessary. Faulty or poorly maintained tools can increase the risk of accidents when working with aluminum sheets. By following these safety precautions, you can minimize the potential risks and ensure a safe working environment when handling aluminum sheets.

- Q: If not, where can i buy some aluminum?

- some contraptions do not use radio waves, a CD participant as an occasion. Radio waves are flying around everywhere, and can intervene with a number of the comfortable singals interior those contraptions, so we want a thank you to dam the waves. some contraptions produce radio-waves, not as an meant output of the gadget, yet as a byproduct of yet another function. Your computing device is an occasion of this. And those contraptions can intervene with the operation of contraptions that are interior attain, like your cellular telephone. So we could give up those by probability produced waves from getting out of the computing device. and in specific circumstances a factor of a gadget makes use of radio waves on a similar time as yet another area of a similar gadget would not, and could be shielded from the different area or it won't artwork right.

- Q: How do you prevent oxidation of exposed edges of aluminum sheets?

- To prevent oxidation of exposed edges of aluminum sheets, there are a few effective methods that can be employed: 1. Apply a protective coating: One of the most common ways to prevent oxidation is by applying a protective coating on the exposed edges of aluminum sheets. This can be done using various types of coatings, such as paint, lacquer, or a specialized protective coating designed specifically for aluminum. These coatings act as a barrier, preventing the aluminum from coming into contact with oxygen and moisture, which are the primary causes of oxidation. 2. Use anodizing: Anodizing is a process in which a protective oxide layer is created on the surface of aluminum. By subjecting the aluminum sheets to an electrolytic process, a controlled and thick layer of oxide is formed, which acts as a barrier against oxidation. Anodizing also provides additional benefits such as improved corrosion resistance and enhanced aesthetics. 3. Implement proper storage and handling: Proper storage and handling practices can also help prevent oxidation of exposed edges. Aluminum sheets should be stored in a dry and well-ventilated area, away from moisture and humidity. It is important to avoid storing aluminum sheets directly on the ground or other surfaces that may cause them to come into contact with moisture. Additionally, gloves should be worn during handling to minimize the transfer of oils from the skin, which can accelerate oxidation. 4. Regular cleaning and maintenance: Regular cleaning and maintenance of aluminum sheets can help prevent oxidation. This involves removing any dirt, grime, or other contaminants that may accumulate on the surface, as they can contribute to the oxidation process. Cleaning can be done using mild soaps or detergents, and a soft cloth or sponge. After cleaning, it is important to thoroughly dry the aluminum sheets to remove any remaining moisture. By implementing these preventive measures, the oxidation of exposed edges of aluminum sheets can be effectively minimized, ensuring their longevity and maintaining their aesthetic appeal.

- Q: Are aluminum sheets suitable for electrical bus bars?

- Yes, aluminum sheets can be suitable for electrical bus bars in certain applications. Aluminum has several properties that make it a viable option for bus bars. Firstly, aluminum is a lightweight material, which can be advantageous in applications where weight reduction is important. Additionally, aluminum has good electrical conductivity, although it is not as conductive as copper. However, aluminum bus bars can still handle high electrical currents and are commonly used in power distribution systems. One downside of aluminum bus bars is that they have a higher resistance compared to copper bus bars. This means that they can generate more heat, especially under high current loads. To mitigate this issue, aluminum bus bars are often designed with larger cross-sectional areas to reduce resistance and dissipate heat more effectively. Another challenge with aluminum bus bars is their susceptibility to oxidation and corrosion. This can be addressed by applying protective coatings or using alloys with better corrosion resistance. It is also important to ensure proper insulation and avoid contact with dissimilar metals to prevent galvanic corrosion. In summary, aluminum sheets can be suitable for electrical bus bars, especially in applications where weight reduction is important. However, careful consideration must be given to factors such as electrical conductivity, heat dissipation, and corrosion resistance to ensure optimal performance and longevity of the bus bars.

- Q: I have heard that consuming aluminum can increase your risk for Alzheimer's later in life.Knowing this, would it increase my risk to eat sweet potatoes cooked in aluminum foil?Even if there is a negligible risk, I still want to know for curiosity reasons.Thank You

- No, I don't think it is dangerous to eat food baked in either side (shiny or matte side) in an aluminum foil. It is dangerous though to put aluminum foil inside a microwave oven to cause those electromagnetic fields to catch fire unless you have a microwave with a cavity magnetron tube to reflect the electromagnetic fields and also don't try to chew and ingest the aluminum foil

- Q: This question asks about the various applications of aluminum sheets within the construction industry.

- <p>Aluminum sheets are widely used in construction for their durability, lightweight, and resistance to corrosion. They are commonly used for roofing and cladding due to their ability to withstand harsh weather conditions. Aluminum sheets are also used in the manufacturing of window frames and doors because of their strength and thermal insulation properties. Additionally, they are utilized in the construction of scaffolding and temporary structures due to their ease of assembly and disassembly. In interior design, aluminum sheets can be used for decorative purposes, such as wall panels and ceilings. Their recyclability also makes them an environmentally friendly choice for construction projects.</p>

- Q: hi my house is wired with aluminum wire and we have this light that has been changed 6 times because originally there was a cheap builders light up there that got replaced with a ceiling fan but the ceiling fan was replaced a couple of times since the remote never worked properly on any of the cieling fans so finally we replaced the cieling fan with just a normal light but now the socket got cracked on the new light by accident. The problem is im wondering if it is safe to put another light up because i have heard aluminum wire breaks easy and the wires have been moved around alot. But if i dont replace the light i wont have a light. We also use the correct wire nuts and anti oxidant on the connections. Also when the 4 cieling fans that had been put up were wired correctly since i have put up many cieling fans up without remotes before. Also Is there a certain number of times aluminum or copper wire can be bent with out having to worry about a fire happening or the wire breaking.

- Hardwood Refinishing low as $1per square foot #2 Common Red Oak Low as $4.45 per square foot, and finished! Brazilian Cherry starting at $7.95 per square foot, and finished (all sizes!) 608-728-2378

- Q: Is it possible to use aluminum sheets as a material for the exterior walls of high-rise buildings?

- <p>Yes, aluminum sheets can be used for exterior walls in high-rise buildings. They are lightweight, durable, and resistant to corrosion, making them suitable for such applications. Aluminum sheets can also be coated or anodized to provide additional protection and aesthetic appeal. They are often used in combination with other materials or as a cladding system to enhance the building's appearance and energy efficiency.</p>

- Q: Are aluminum sheets resistant to staining?

- Yes, aluminum sheets are generally resistant to staining due to their natural ability to form a protective oxide layer on the surface, which prevents corrosion and staining.

- Q: Are aluminum sheets suitable for use in harsh chemical environments?

- No, aluminum sheets are not suitable for use in harsh chemical environments.

Send your message to us

2016 HD Aluminium Metal Art Pictures Print on 4 By 8 Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 carton

- Supply Capability:

- 20000 carton/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords