Aluminum Sheets 1/4 Thick for Deoxidation in Steel Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Bar for Deoxidation of Steel Production Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Bar for Deoxidation of Steel Production:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

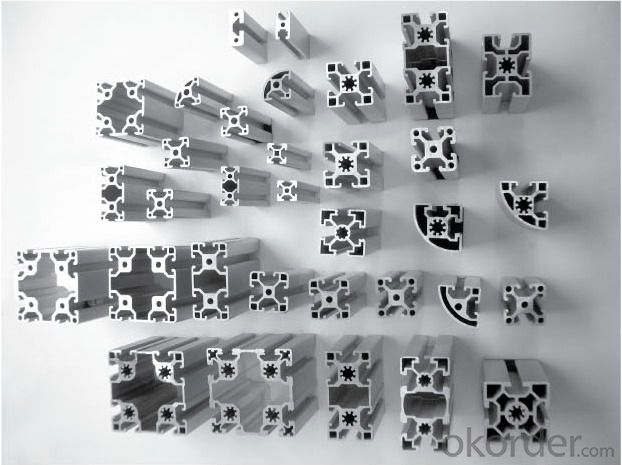

Images of Aluminium Bar for Deoxidation of Steel Production:

Aluminium Bar for Deoxidation of Steel Production Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What is the bending radius for aluminum sheets?

- The bending radius for aluminum sheets can vary depending on the thickness and alloy of the sheet. Generally, for thinner sheets (around 1-3 mm), the recommended bending radius is approximately 1.5 times the sheet thickness. For thicker sheets (over 3 mm), the bending radius can be increased to around 2.5 times the sheet thickness. However, it is important to note that these are general guidelines and the specific bending radius may need to be adjusted based on the specific application and the desired outcome. It is always recommended to consult with a professional or refer to specific technical data sheets provided by the manufacturer for accurate bending radius information.

- Q: This question asks if aluminum sheets are appropriate for use in regions with cold temperatures.

- <p>Aluminum sheets are generally suitable for use in cold climates. They have excellent resistance to corrosion and maintain their structural integrity in low temperatures. However, aluminum is a good conductor of heat, so it can be prone to heat loss if not properly insulated. For outdoor applications in cold climates, it's important to ensure that aluminum structures are well-insulated to prevent heat transfer. Additionally, aluminum's malleability can make it susceptible to denting or damage from ice and snow, so protective measures may be necessary.</p>

- Q: This question asks for an overview of the various types of coatings applied to aluminum profiles used in exterior cladding systems.

- <p>Aluminum profiles for exterior cladding are often coated to enhance their durability, weather resistance, and aesthetic appeal. Common types of coatings include: 1. Anodizing, which creates a protective oxide layer on the aluminum surface. 2. Powder coating, a popular method that provides a durable and colorful finish. 3. Fluorocarbon coating, known for its excellent weathering and UV resistance. 4. PVDF (Polyvinylidene Fluoride) coating, highly resistant to chemicals and suitable for marine environments. 5. Electrophoretic coating, which offers a smooth, even finish. 6. Hot-dip galvanizing, a process that coats aluminum with a protective layer of zinc. Each coating type has specific advantages and is chosen based on the performance requirements and environmental conditions of the project.</p>

- Q: Would you please tell me what putty to use on the aluminium board, what kind of putty, and the painting process?

- Applied atomic ash.Consider adding an interface agent, that is, applying an interfacial agent on the aluminum plate, and then applying a topcoat on the interface agent after drying.

- Q: i m not sure if aluminum hydroxide is a acid or base. if somebody could help me, i will really appreciate.If u can could you also tell me if im wrong or right about the following substances:- pepsi cola is acid- vinegar is a base- ammonia is a base- aluminum hydroxyde is ?thank u for your help.

- as stated anything ending in -OH is a base, therefore AlOH is a base. the others are correct except for vinegar, it is an acid, not a base.

- Q: Can aluminum sheet be used for decorative purposes?

- Indeed, aluminum sheet serves as a suitable option for decorative uses. With its adaptability, aluminum can be effortlessly molded, trimmed, and fashioned into an assortment of patterns, rendering it an excellent choice for embellishing ventures. Whether utilized to fashion decorative paneling, sculptures, signage, furnishings, or numerous other ornamental components, aluminum proves itself indispensable. Furthermore, aluminum can be anodized or painted in an extensive array of hues, enabling additional personalization and accentuating its visual allure. Additionally, its lightweight composition and corrosion resistance render it a pragmatic selection for both indoor and outdoor decorative endeavors.

- Q: My mother has this idea that when her boyfriend puts coals from the wood stove in aluminum containers to warm the house that inhaling the fumes can cause Alzheimer's disease later in life. I am just curious about the truth of it.

- yes, aluminum is seriously bad, I knew a man that worked with aluminum and he was only 26 years old and his brain went completely blank. Research it.

- Q: What is the typical density of aluminum sheets?

- Aluminum sheets usually have a density of around 2.7 grams per cubic centimeter (g/cm³). Unlike steel and other commonly utilized metals, aluminum is known for its lightweight nature and relatively low density. This characteristic makes aluminum sheets an ideal choice for multiple applications that require a material with less weight, including the aerospace industry, automotive manufacturing, and construction.

- Q: Are aluminum sheets suitable for aircraft panels?

- Indeed, aircraft panels can be made from aluminum sheets. The aviation industry extensively employs aluminum due to its exceptional strength-to-weight ratio, rendering it an ideal choice for constructing aircraft structures that are both lightweight and robust. Aluminum sheets are frequently utilized for aircraft panels owing to their durability, resistance to corrosion, and ease of fabrication. Moreover, aluminum can be effortlessly molded and welded, enabling the creation of intricate panel shapes. Furthermore, aluminum possesses commendable electrical conductivity, a crucial factor in the efficient operation of diverse aircraft systems. In summary, the utilization of aluminum sheets for aircraft panels plays a pivotal role in ensuring the aircraft's structural integrity and performance.

- Q: Can aluminum sheets be bent or formed?

- Indeed, it is possible to bend or shape aluminum sheets. Aluminum, being a remarkably malleable and ductile metal, can be effortlessly molded or bent without fracturing. This attribute renders it a favored option for a wide range of purposes, including the production of automotive components, aircraft structures, and household products. Diverse techniques, such as press braking, roll bending, and stretch forming, can be employed to bend or shape aluminum sheets. By utilizing these methodologies, the aluminum sheets can be formed into diverse angles or curves to fulfill precise design prerequisites.

Send your message to us

Aluminum Sheets 1/4 Thick for Deoxidation in Steel Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords