Water Pump Serie Submersible Sewage Pump From China On Top Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Specifications

1)High performance

2)Mechanical seal

3)Cast iron impeller or bronze impeller

4)Lower vibration water pump

5)Large flow

2.Packaging & Delivery

Packaging Detail: | export wooden cases |

Delivery Detail: | within 30 days once receipt of 30% T/T prepayment |

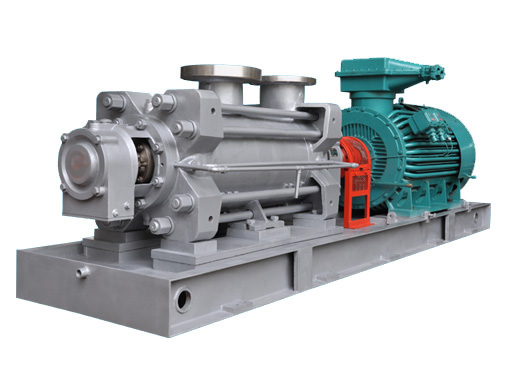

BPO Irrigation Centrifugal Split Water Pump

3.FEATURES

BPO series single-stage double-suction open type centrifugal pump self-researched by the Company after absorbed advanced technology of similar products and combined application requirement of various customers. The series pump adopts excellent hydraulic model, wider type spectrum and better structure. Pump casing is produced by special machine tool, which ensures concentricity among shaft bearing, shaft and pump case, and provides better reliability and maintainability. Apply to municipal water supply and drainage, water circulation of air conditioner, agricultural hydraulic engineering, such as irrigation, drain flooded fields etc., industrial water supply system, firefighting system, water supply and drainage of

heating system, transportation of clean water

4. OPERATING CONDITION

a)Rotate speed: 2950r/min, 1480 r/min, 980 r/min, 730 r/min

b)Flow range: 64.4~9810m3/h

c)Delivery lift: =200m

d)Medium temperature: =80 ,

e)product adopting special materials: -20 ~120

f)Ambient temperature: Lower than 40

g)Operating pressure up to achieves 2.5MPa

5. MATERIAL

a)Pump casing: Cast iron or magnesium iron

b)Pump cover: Cast iron or magnesium iron

c)Impeller: Cast iron, magnesium iron or tin bronze

d)Sealing ring: Cast iron or tin bronze

e)Pump shaft: 45# steel plated with chrome

f)Dynamic and static mechanical sea: Hard carbide, graphite

g)Configuring other material according to requirement is allowable

Rated flow | 10(m3/h) |

Rated head | 26m |

Rated power | 1.5Kw |

Voltage | 220V |

Rated Current | 7.2A |

Rated speed | 2860r/min |

Discharge diameter | 50mm |

6.Conditions of use

Pumps used in the following conditions should be continuously to work properly:

1. For water pumps suitable medium, medium temperature shall not exceed + 40°C

2. The medium PH value between 6.5 ~ 8.5

3. The volume of medium containing solid impurity is less than 0.1%, the size is not more than 0.2 mm

4. The power frequency 50 hz, voltage for single-phase 220 v, 380 v, three-phase voltage fluctuation range for rating of 0.9 to 1.1 times

5. Diving depth of no more than 5 m, is not suitable for irrigation and drainage of sewage and chemicals.

- Q: When you are replacing a water pump on a vehicle, should you replace the timing belt on the vehicle as well?

- if the water pump is driven by the timing belt then its a good idea to change both as the labor to get into water pump is the same as to do the timing belt. I'd spend the extra $50 for the belts and change them while I'm in there and that way you'll be ahead of the game instead of paying (or taking the time) to do it twice at two different times

- Q: I am going to replace the timing belt , tesioner and idler bearing on my 2000 daewoo leganza. I noticed some of the kits have water pumps too. It is likely to break like the timing belt?

- I would suggest to replace the car itself.

- Q: Assuming that my water pump standard flow is 20m3/h, tolerance value requirements is + 8%, then is not traffic 22m3/h is not qualified?

- Tolerance coefficient is due in the manufacturing process, will, so each pump products are possible shapes and sizes do not conform to the pattern of the situation, and ensure the test results in the value (operating point) when compared, should be allowed to have a certain tolerance. It should be noted that these tolerances are only relevant to the actual pump and do not involve test conditions and measurement uncertainties.If the pump at a certain working point (the same lift) standard (Design) flow of 20m3/h, the actual flow of 22m3/h, indicating that the pump in the design process has unreasonable place, resulting in waste of power. Deviations from the manufacturing process usually have no positive deviation.

- Q: Suppose the liquid temperature range for the water pump is -20 .. 90 °C. However it should be worked under liquid temperature upto 180 °C. For this, what has to to be done?

- (edited) The physical size of the pumping arrangement was not described. I assume that the pump has all metallic components because of the high (194 F) 90degC design operating temperature. There may be some problem with an elastomeric bellows in a mechanical seal at the 180degC (356F) temperature. Other than that, there should be no problem with the temperatures as far as the pump is concerned. There may be a need for shaft cooling to protect the standard electric motor and possibly the flexible drive coupling arrangement. (edit) Depending on the physical size, rotating speed and drive arrangement, a special coupling set-up may be needed to accommodate any potentially wide swing in operating temperatures. From ambient to 180degC there will be about a 160C (288F) variation. The liquid will be either a salt or a glycol brine solution for freeze protection at the lower temperatures. (edit) That same concentration will provide some elevation of the boiling temperature and therefore a reduction of the pressure of the water solution needed to prevent boiling. ( 130 psig is the saturation pressure of plain water at that elevated temperature.) This can be found on the charts provided by the glycol suppliers for the various glycol and salt solution characteristics. To prevent cavitation you may need to pressurize the suction. If the proposed pressure of the system is already above the vapor pressure of the solution at that maximum temperature, you may already be OK. A motor with high temperature windings may be considered.

- Q: The water pump doesn't seem to be leaking but I do have a leak under the engine in a place I can't get to. The water doesn't seem to be getting to the upper hoses of the engine. I do hear a odd sound like lose rocker arms but its hard to tell where its coming from.This engine is to big for this boat there is no room to work on it except to pull the engine. What was Four Winns thinking??? A simple fix is a major repair. Thanks

- drive your boat as fast and far as you can. at that point you will find if anything is broken. i say if it ain't broke don't fixit!!! if it brakes then you know what to fix. since it hard to get to your water pump just take your motor out and rebuild the whole thing. welcome to boating.

- Q: I am looking for foot peddals and one of those pumps that you can use to pump excess water out of the cockpit..... any Ideas where to look for the cheapest of both...I checked Dunhams and *****.

- Northwest okorder / They also have a section where people sell their second-hand gear, you might look there as well.

- Q: I have a 1.5 horse Power Hit and Miss engine? Is it possible to buy a water pump I could run off of the hit and miss engine that would pump water from a river over a big hill and little ways and into a water tank or is this just a waste of time. How much water could I pump at a time? A trickle or a gush of water? When I say hill I don't mean like a little hill in your yard I mean a hill you have to hike up? If you don't know are there any resources I could access? Where could I buy such a pump if there is one?

- A horse and a half won't do much. You would be better off with a hydraulic ram type pump if you can get about a 10 or 15 foot fall before the ram. It will pump about 4 or 5 times the height of the fall, but in small quantities. It will run 24/7 without gasoline, so it will fill a tank over a long period of time. The railroads used them during the steam era when they had huge water towers out on the plains.

- Q: old sbc v8 water pump from oreilly's came apart and the fan ate up my serpentine belt, power steering pump pulley, clutch fan obviously, and put 5 holes in my new aluminum radiator. What will they cover? Remanufactured limited lifetime warranty. '78 chevy k10 350 sbc

- the warranty will replace the water pump. the rest is on you my friend. if you had checked the water pump ealier when the bearing first started to make noise this would not have happened.

- Q: It is used in a water pumping station.

- What Is A Submersible

- Q: i have a significant stream of water running out of the coolant return side of the engine under the coolant pipe on a 1997 caravan i will lose a gallon and then it stops until the engine heats up and of course more comes out with expansion

- You will have to remove the AC compressor, all of the drive belts, alternator bracket, power steering pump and bracket, motor mount, timing cover, and the timing belt. This job calls for 4.3 hours and I was able to do one in about 3. If you really want to attempt this yourself, let me know and I will give you detailed step by step instructions to do it, right down to the timing marks and what size each bolt is. If you have never done a water pump/timing belt on any car before, I strongly recommend you don't attempt this repair yourself. The 3.0 really isn't a bad one to do, if you have the tools and some mechanical knowledge and ability.

Send your message to us

Water Pump Serie Submersible Sewage Pump From China On Top Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords