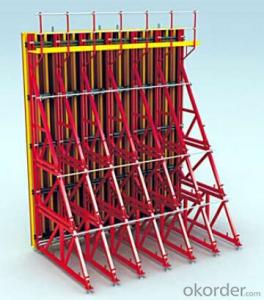

Single-side Bracket Steel formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

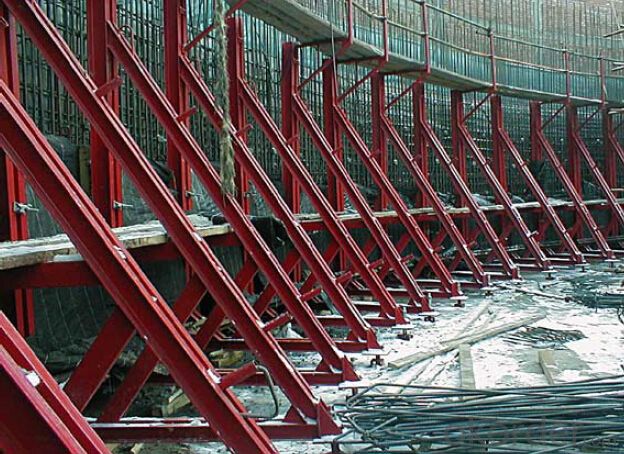

Single-side Bracket:

During single-sided concreting, the concrete pressure is transferred into the sub-structure by

means of the single-side bracket.

Characteristics:

◆ For concrete heights up to 8.0m and a fresh concrete pressure up to a maximum of 60KN/m2.

◆ Good standard performance and versatility.

◆ Fast element coupling, all units can be quickly connected.

◆ The finished wall is excellent and absolutely waterproof.

◆ Optimized sizes for transportation.

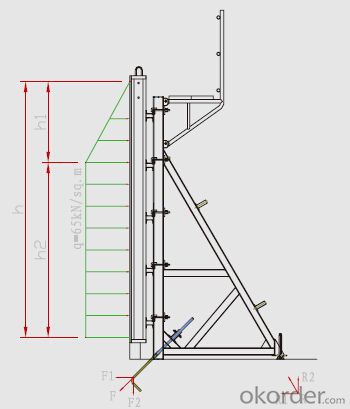

Design Principle:

There is no wall-through tie-rod in the single-side bracket system. The whole system is adjusted by

the anchor system and the regulator system.

The stress situation from the sketch above.F1 can resist the side pressure of the concrete and F2

can resist the rising force. R can not only bear the gravity force of the bracket, but also the side

pressure of the concrete. This stress system is simple, reasonable and also with convenience and

high safety.

- Q: 1 tunnel lighting design steps, 2 teacher said to design a template, is not to create a tunnel, and then according to the numerical calculation of what?

- The pupil is 5 times as fast as the increases, which makes the dark adaptation time to defend much longer. Cone cells can produce or reduce pigment in 10 ~ 12min, and the rod cells are almost 60min need to produce all of the pigment, which makes it very difficult for people to adapt to a very dark environment. How long does it take, depending on the extent of illumination.

- Q: How the tunnel template is calculated

- The man's answer is analysis procedure of tunnel structure analysis of finite element modeling.The design of tunnel lining formwork and support must have enough strength, rigidity and stability. The utility model has the advantages of no convex concave, no deviation, no distortion, and the appearance of the concrete is regular and beautiful.

- Q: For example, lining, invert, bias and so on words,, to answer the full thank you

- Bias: refers to the formation of the tunnel, resulting in uneven pressure. To provide you with a few books you go to see the explanation. The site is easy to understand.

- Q: How to fill in the tunnel template

- The template is firm and smooth, there is no error, such as leakage

- Q: How to design the general layout of the tunnel construction organization design

- Feng Shui pipeline, transformer location, power lines, warehouses, steel parts processing

- Q: What is the width of a ring in a tunnel

- Of course, the assembly of the tunnel, such as subway shield tunnel, a ring is the length of the shield segment, there are 1.0m, 1.2m, 1.5m, 2.0m.

- Q: Tunnel construction procedure A cycle of steps

- The construction and tunnel portalWith the support from top to bottom layered excavation hole slopes, and Myeong Dong, and permanent and temporary outside waterproof and drainage should be first, make the surface smooth water, avoid surface water erosion on slope. Is necessary to take artificial slope repair, prevent overbreak, reduce disturbance to the adjacent area; excavation slope will be used in the design of the door, reducing exposure to rock weathering, support to follow, within the jurisdiction for high slopes, if not timely, can not guarantee the safety, and many of the human condition waste,The lining must check and recheck side wall foundation Myeongdong geologic condition and the bearing capacity of the foundation, to meet the design requirements, measurement lofting, frame formwork support, assembling reinforcement, inside and outside the template, the first wall arch integral casting lining concrete, mixing pump into the mold, insert type vibrator with attached type vibrator tamping compaction device.For the construction of portal portal with cut bamboo, also for cutting bamboo cut, plane mounted wooden formwork according to the slope, the slope angle and side end die die fixed into a whole.The waterproof layer and backfillingAfter the completion of open cut tunnel lining strength up to 50% can be removed outside the mold, with a waterproof layer, each layer of backfill should be symmetrical on both sides of the height difference is not greater than 30cm, not more than 50cm, after re stratified backfill to the vault, filled to the completion of a good surface aquifuge.

- Q: What is the simple calculation method of the tunnel excavation unit price

- Parameter valuationThe valuation of parameter method is the method of calculating the multiplication coefficient according to a certain cardinal number or the custom formula. This method is simple and clear, but the biggest difficulty is the scientific formula, accuracy is difficult to grasp. This method is mainly applicable to the construction process must occur, but it is difficult to predict the specific items in the bidding, but can not separate the project content of the project measures. If the valuation night construction fees, two handling fee, rain during construction can be used in this method.

- Q: What is the first project of tunnel constructionNow to do some of the tunnel program, you need to be the first to list out, a total of what? I know that the first branch, two lining, inverted arch, tunnel, pavement these

- Summary of construction of the first two tunnel lining

- Q: 12 meters of the tunnel car, under normal circumstances, one of the two months to be able to cast a few models?

- If the reinforcement in advance or tied to the design of no reinforcement, the normal situation down the car, plus the plug plate, pouring concrete

Send your message to us

Single-side Bracket Steel formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords