Steel Tunnel Formwork for Building Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

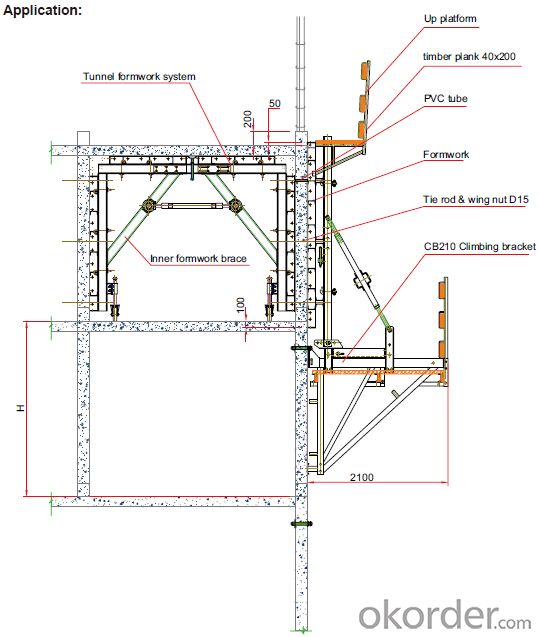

Building Tunnel Formwork:

A compositional steel formwork system mainly used in the building which has regular structure

without beams, the excellent formwork system can make the integral pouring for the wall & slab

easily achieved.

Characteristics:

◆ High stiffness, make perfect shape for concrete.

◆ Easy operation, save labor and force.

◆ Fast forming, repeatedly turnover.

- Q: Loess tunnel construction quality control points

- The main points of concrete construction of tunnel invert:1) should advance concrete arch wall concrete construction of inverted arch arch and the construction should be removed before water, slag and other sundries, false

- Q: How to put the positioning point is based on what is mainly based on my novice, do not

- The next two large positioning along the side mode, re positioning of two small side mode along the point, then turn to check the center point and elevation, if not the positioning deviation is complete, then re adjust the positioning deviation! If you have time to measure the location of the site can be set up, then you do not nail this method, the five points directly to the elevation and mileage can be controlled for a long time

- Q: How to fill in the tunnel template

- There seems to be a quality inspection form,Send a template to see

- Q: I would like to ask the tunnel hydraulic trolley steel template design is the use of what software

- You are talking about the design of the tunnel two lining car software.

- Q: Tunnel steel arch behind the steel mesh after a layer of fine iron wire mesh what effect is there?

- 3, advance small catheter grouting small catheter with diameter of phi 32-50mm steel pipe, the tip of the tube and tube holes for special processing. The first row with drill drilling pipe. Row spacing is 30cm, fan shape, elevation of 5 degrees to about 8 degrees. The length is 2.25m, a single fluid grouting (cement) or double grout (cement water glass slurry). Adjust the grouting pressure according to the soil.

- Q: What are the reasons for the two lining concrete lining of the tunnel?

- (3) the concrete pump tube, vibration rod and other mechanical repeated impact, workers trample or vibrator touch bar, caused by displacement and deformation of steel exposed.

- Q: What is the width of a ring in a tunnel

- The car is generally long 9m can be a one-time pouring, a ring is a pouring two lining length

- Q: Tunnel construction procedure A cycle of steps

- Excavation and support of shallow buried and broken section of V grade surrounding rock of portalHole wayThe thin covering layer, poor geological conditions, when the depth of excavation to the arch line, first into the hole wall and the guide pipe shed, the open cut tunnel lining after the completion of the long pipe shed is overlapped on the Dong, to form a fixed end of pipe roof support, opening into the inner wall in the protection of pipe roof under the heading of the two side wall to stagger the footage before and after (5 ~ 10m). If there is a small spacing must also be set prestressed anchor.

- Q: Two tunnel lining reinforced concrete template to price behavior can be contracted

- This problem should belong to the industry confidential!If the two lining of the tunnel is pure manual, the normal price is between 800 and 650,

- Q: 12 meters of the tunnel car, under normal circumstances, one of the two months to be able to cast a few models?

- If the reinforcement in advance or tied to the design of no reinforcement, the normal situation down the car, plus the plug plate, pouring concrete

Send your message to us

Steel Tunnel Formwork for Building Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords