Steel Frame Easy Connection Formwork with Adjustable Steel Clamp

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

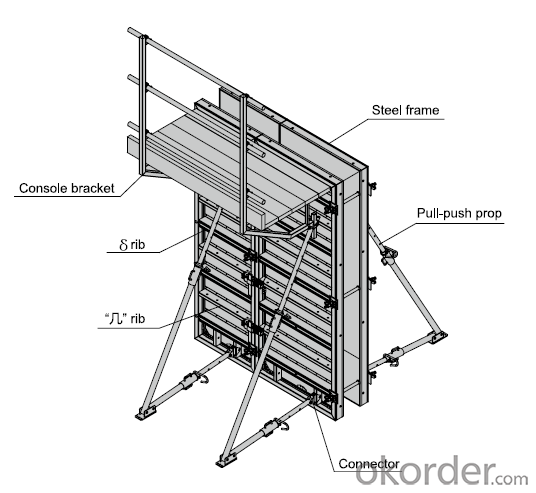

1. Structure of Steel Frame Formwork

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

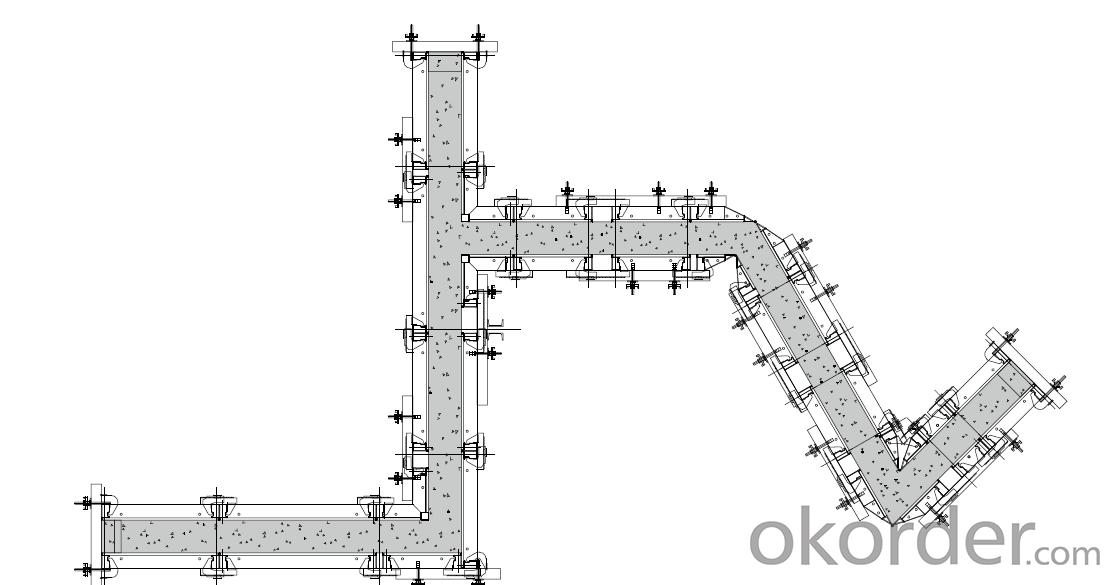

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

3. Steel Frame Formwork Images

4. Steel Frame Formwork Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

5. FAQ of Steel Frame Formwork

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel Frame Formwork , please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel Frame Formwork , we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: What are the different types of stripping methods used with steel frame formwork?

- There are several different types of stripping methods used with steel frame formwork, including crane stripping, hydraulic stripping, and manual stripping. Crane stripping involves using a crane to lift and remove the formwork from the concrete structure. Hydraulic stripping utilizes hydraulic jacks to lift and separate the formwork from the concrete. Manual stripping involves manually dismantling and removing the formwork by hand. These methods offer varying degrees of speed, efficiency, and labor requirements depending on the specific project and requirements of the formwork system.

- Q: What are the cost implications of using steel frame formwork?

- The cost implications of using steel frame formwork can vary depending on several factors. One of the main advantages of steel frame formwork is its durability and longevity. Steel is a strong and sturdy material that can withstand multiple uses without losing its shape or structural integrity. This means that steel frame formwork can be used for multiple construction projects, reducing the need for frequent replacements. However, the initial cost of steel frame formwork can be higher compared to other types of formwork materials such as wood or aluminum. Steel is generally more expensive to manufacture and purchase, which can increase the upfront cost of using steel frame formwork. Additionally, the weight of steel frame formwork can also affect the overall cost. Steel is a heavy material, which means that transportation and handling costs may be higher compared to lighter materials. This is particularly relevant when considering the logistics of moving the formwork to different construction sites. On the other hand, steel frame formwork offers increased efficiency and productivity during the construction process. Steel frames are typically prefabricated, making them easy to assemble and disassemble on-site. This saves time and labor costs, as workers can quickly set up and dismantle the formwork. Furthermore, steel frame formwork provides excellent dimensional accuracy and stability, resulting in high-quality concrete finishes. This reduces the need for additional finishing work, saving both time and money. Overall, while steel frame formwork may have higher upfront costs, its durability, reusability, and efficiency can lead to cost savings in the long run. Additionally, the high-quality finishes achieved with steel formwork can contribute to overall project savings.

- Q: Can steel frame formwork be used for sports and recreational facilities construction?

- Yes, steel frame formwork can be used for sports and recreational facilities construction. Steel frame formwork offers high strength and durability, making it suitable for constructing large-scale structures like stadiums, sports arenas, and recreational facilities. It provides excellent support for concrete pouring, ensuring the integrity and stability of the final structure. Additionally, steel frame formwork can be easily assembled and disassembled, allowing for efficient construction processes and potential reuse in future projects.

- Q: What are the key considerations for selecting the appropriate steel frame formwork supplier for international projects?

- When selecting an appropriate steel frame formwork supplier for international projects, there are several key considerations to keep in mind. Firstly, it is crucial to assess the supplier's experience and reputation in the industry. Look for a supplier with a proven track record of successfully delivering steel frame formwork for international projects. This can be done by reviewing their portfolio, client testimonials, and industry certifications. Secondly, consider the supplier's ability to provide customized solutions. International projects often have unique requirements and specifications, so it is important to work with a supplier who can tailor their steel frame formwork to meet these specific needs. Additionally, logistics and supply chain management play a significant role in selecting the appropriate supplier. Look for a supplier with a robust global distribution network, efficient shipping processes, and the ability to handle any necessary customs or import/export procedures. Furthermore, the quality and durability of the steel frame formwork are essential factors to consider. Ensure that the supplier uses high-quality materials and has stringent quality control measures in place. This will ensure that the formwork will withstand the demands of international projects and provide long-lasting performance. Lastly, consider the supplier's customer service and support capabilities. International projects can be complex and may require ongoing assistance and technical guidance. Choose a supplier who is responsive, offers reliable after-sales service, and can provide timely support when needed. By considering these key factors, you can select an appropriate steel frame formwork supplier for international projects that will meet your project's requirements, deliver high-quality products, and provide the necessary support throughout the project duration.

- Q: What are the different types of formwork ties used in steel frame formwork?

- There are several different types of formwork ties used in steel frame formwork, each with its own unique characteristics and advantages. Some of the most common types include: 1. Snap Ties: These are the most basic and commonly used formwork ties. They consist of two flat plates with a threaded rod in between. Snap ties are easy to use and provide solid connections between the formwork panels. 2. Wedge Ties: This type of tie consists of a flat plate that is inserted into a slot on the formwork panel. A wedge is then driven into the slot to secure the tie in place. Wedge ties are quick and easy to install and provide a strong connection. 3. Coil Ties: Coil ties are made from a continuous loop of wire that is threaded through the formwork panels. They are secured by twisting the ends together. Coil ties are versatile and can be used for a wide range of formwork applications. 4. She-Bolts: She-bolts are used in situations where it is not possible to use external ties. They consist of a threaded rod that is inserted into a hole drilled through the formwork panel. A washer and nut are used to secure the tie in place. 5. Cone Ties: Cone ties are similar to snap ties but have a conical shape on one end. This allows for easy removal of the tie after the concrete has cured. Cone ties are commonly used in situations where the formwork needs to be removed quickly. 6. Flat Ties: Flat ties are made from flat steel bars that are inserted through the formwork panels. They are secured using nuts and washers on both sides of the formwork. Flat ties provide a strong and secure connection. 7. Z Ties: Z ties are named for their Z-shaped profile. They are inserted into the formwork panels and secured using nuts and washers. Z ties are commonly used in situations where high load capacity and stability are required. These are just a few examples of the different types of formwork ties used in steel frame formwork. The choice of tie will depend on the specific requirements of the project, including the type of formwork being used, the load capacity required, and the desired ease of installation and removal.

- Q: Are there any environmental considerations when using steel frame formwork?

- Yes, there are several environmental considerations when using steel frame formwork. Steel production has a significant carbon footprint and contributes to greenhouse gas emissions. Additionally, the extraction of raw materials for steel production can lead to habitat destruction and ecosystem disruption. However, steel formwork can be reused multiple times, reducing the need for new materials and minimizing waste generation. Proper disposal and recycling of steel formwork after its useful life should also be considered to minimize environmental impact.

- Q: Can steel frame formwork be used in curved or irregular shapes?

- Yes, steel frame formwork can be used in curved or irregular shapes. Its flexibility and adaptability make it suitable for creating customized formwork designs to accommodate various shapes and sizes.

- Q: What are the different types of supports used with steel frame formwork?

- Construction projects utilize various types of supports in conjunction with steel frame formwork. These supports play a crucial role in establishing stability and facilitating the formwork system's ability to bear the weight and pressure generated by the poured concrete. 1. One type of support, known as adjustable steel props, consists of vertical supports that can be modified to different heights using threaded rods. These props are commonly employed alongside steel frames to reinforce horizontal beams or slabs. 2. Another support option is steel shoring systems, which encompass vertical steel tubes equipped with adjustable steel beams or U-heads at their upper ends. These systems are utilized to bolster large slabs or beams during construction. 3. Scaffolding can also serve as supports for steel frame formwork. It furnishes a stable working platform for workers and can be effortlessly adjusted to varying heights. 4. Timber or plywood bracing is sometimes employed to provide supplementary support to steel frame formwork. These bracings are placed diagonally or horizontally between the steel frames to enhance stability. 5. Hydraulic jacks are another resource that can furnish temporary support to steel frame formwork. These jacks are adjustable and can be used to elevate or lower the formwork as required. It is important to note that the selection of supports hinges upon the specific requirements of the construction project, encompassing factors such as the structure's size and shape, the weight of the poured concrete, and the height of the formwork system. The design and installation of these supports should be entrusted to experienced professionals to ensure safety and structural integrity.

- Q: Is steel frame formwork resistant to fire?

- Steel frame formwork is indeed fire resistant. Not only is steel a non-combustible material, but it also does not aid in the propagation or escalation of fires. Its melting point, which usually reaches approximately 1370 degrees Celsius, allows it to endure high temperatures without compromising its structural integrity. Hence, steel frame formwork proves to be a secure and dependable option for construction ventures that prioritize fire resistance. Moreover, steel's resilience and robustness guarantee that the formwork remains undamaged even in the most severe fire circumstances, offering additional safeguarding to the developing structure.

- Q: The steel frame structure of short column reinforced head after bending and shear module and embedded parts embedded anchor bolts. How to do, can be reinforced structure elbow section

- This is a critical force, not only to cut, the anchor bolt installation, after a gust of wind blowing a separate steel column may be blown down, the main force is the base elbow here

Send your message to us

Steel Frame Easy Connection Formwork with Adjustable Steel Clamp

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords