Steel Frame Formwork of Flexible Assemble and Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

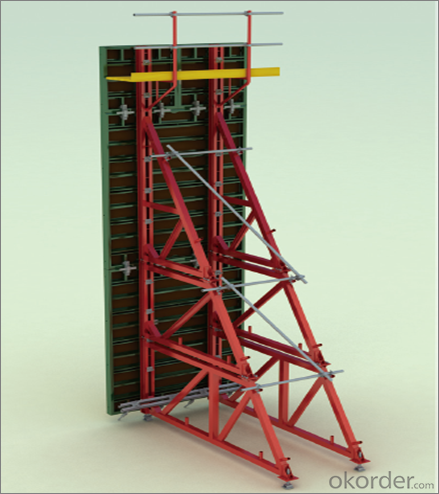

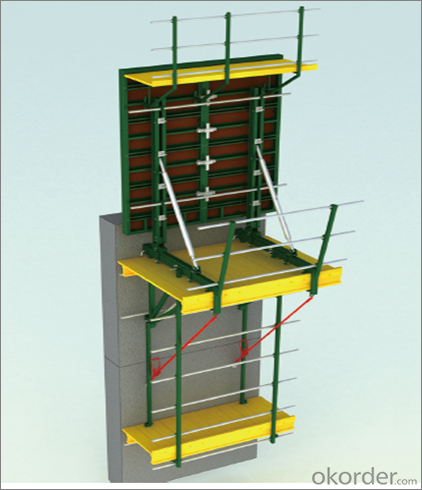

1. Structure of Steel Frame Formwork GK120

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork GK120

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

3. Steel Frame Formwork GK120 Images

4. Steel Frame Formwork GK120 Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

-There is a prizing part designed in the corner, which can help to position and remove formwork easily.

-The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

-The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

5. FAQ of Steel Frame Formwork GK120

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel Frame Formwork GK120, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel Frame Formwork GK120, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Are there any disadvantages to using steel frame formwork?

- There are indeed a few drawbacks to utilizing steel frame formwork. To begin with, in comparison to alternative formwork types like timber or aluminum, steel frame formwork tends to be more expensive. This can dissuade smaller construction projects or those with limited budgets. Furthermore, due to its relatively heavy nature, steel frame formwork necessitates machinery or additional manpower for handling and installation. This can result in increased overall construction time and costs. In addition, steel frame formwork lacks the flexibility of other formwork types. It is typically prefabricated to meet specific project requirements, making it less easily adjustable or adaptable to changes in design or dimensions. Lastly, regular maintenance and proper storage are necessary to prevent rust and corrosion of steel frame formwork. If not properly maintained, the formwork may deteriorate over time, posing safety risks and requiring expensive repairs or replacement. Despite these drawbacks, steel frame formwork offers numerous advantages such as high strength, durability, and reusability. As a result, it is commonly employed in large-scale construction projects where the benefits outweigh the drawbacks.

- Q: What are the different types of formwork corners used in steel frame formwork systems?

- There are typically two types of formwork corners used in steel frame formwork systems: internal corners and external corners. Internal corners are used when the formwork needs to be supported from the inside, while external corners are used when the formwork needs to be supported from the outside. Both types of corners are designed to provide stability and reinforcement to the formwork structure, ensuring the proper alignment and stability of the concrete during the pouring and curing process.

- Q: How does steel frame formwork affect the overall sustainability goals of a construction project?

- Steel frame formwork can have a significant impact on the overall sustainability goals of a construction project. Firstly, steel is a highly durable material that can withstand the rigors of construction, resulting in a longer lifespan for the formwork system. This increased durability reduces the need for frequent replacements, saving resources and reducing waste. Moreover, steel frame formwork is reusable, meaning it can be dismantled after use and used again in future projects. This not only reduces the demand for new formwork materials but also minimizes the amount of waste generated during the construction process. By promoting the reuse of formwork, steel frames contribute to a circular economy approach that aims to reduce resource consumption and waste generation. In addition, the use of steel frame formwork facilitates efficient and precise construction processes. The formwork system is designed to provide accurate dimensions and smooth finishes, resulting in reduced material waste and energy consumption. Furthermore, steel is a highly recyclable material, meaning that at the end of its life cycle, it can be easily recycled and used in the production of new steel products, reducing the demand for virgin materials and the associated environmental impact. Lastly, steel frame formwork offers flexibility in design and construction, allowing for innovative and sustainable building practices. Its strength and versatility enable the construction of complex and efficient structures, such as high-rise buildings or large-span structures, which can maximize energy efficiency and minimize the overall environmental impact of the project. Overall, steel frame formwork positively affects the sustainability goals of a construction project by promoting durability, reusability, efficiency, and recyclability. Its use contributes to reducing resource consumption, waste generation, and environmental impact, aligning with the principles of sustainable construction practices.

- Q: How does steel frame formwork contribute to the overall structural integrity of a concrete structure?

- Steel frame formwork contributes to the overall structural integrity of a concrete structure by providing a strong and rigid support system for the concrete during the pouring and setting process. It ensures that the concrete is evenly distributed, prevents any sagging or deformation, and allows for accurate shaping and alignment of the structure. Additionally, the steel frame formwork helps to resist external forces such as wind and earthquake loads, enhancing the durability and stability of the concrete structure over time.

- Q: Can steel frame formwork be used for sports and recreational facilities construction?

- Yes, steel frame formwork can be used for sports and recreational facilities construction. Steel frame formwork is a versatile construction system that provides a strong and durable framework for concrete structures. It is widely used in various construction projects, including sports and recreational facilities. The strength and rigidity of steel make it an ideal choice for constructing large and complex structures, such as stadiums, indoor arenas, swimming pools, and gymnasiums. Steel frame formwork can easily support the weight of the concrete and withstand the forces exerted by the structure. This ensures the stability and integrity of the facility, providing a safe and functional space for sports and recreational activities. Additionally, steel frame formwork offers flexibility in design and allows for customization according to the specific requirements of the facility. It can be easily adjusted and modified to accommodate different architectural features, such as curved walls, grandstands, and unique shapes. This allows architects and designers to create aesthetically appealing and innovative sports and recreational facilities. Moreover, steel frame formwork is known for its durability and longevity. It can withstand harsh weather conditions, heavy loads, and regular wear and tear, making it suitable for long-term use in sports and recreational facilities. The use of steel also contributes to the sustainability of the construction, as it is a recyclable material and can be reused or repurposed in the future. In conclusion, steel frame formwork is a suitable choice for the construction of sports and recreational facilities. Its strength, flexibility, and durability make it an ideal construction system to support the design and functionality of such structures.

- Q: Can steel frame formwork be used for both small and large-scale infrastructure projects?

- Yes, steel frame formwork can be used for both small and large-scale infrastructure projects. Steel frame formwork is a versatile and durable solution that can be tailored to various project sizes and requirements. It offers several benefits, including high strength and stability, which make it suitable for large-scale projects such as bridges, tunnels, and high-rise buildings. For small-scale projects, steel frame formwork is also a practical option. Its flexibility allows for easy customization and adjustment, making it adaptable to different shapes and sizes. Additionally, steel frame formwork can be re-used multiple times, reducing costs and increasing efficiency for smaller projects with limited budgets. Moreover, steel frame formwork provides excellent concrete finishing and accuracy, ensuring high-quality results regardless of the project scale. Its robust construction ensures stability and safety, even under heavy loads, making it suitable for both small and large-scale infrastructure projects. Overall, steel frame formwork is a versatile and reliable solution that can be used effectively for various infrastructure projects, regardless of their size.

- Q: Can steel frame formwork be easily adjusted or modified during the construction process?

- Steel frame formwork offers the flexibility and convenience of being easily adjusted or modified throughout the construction process. These systems are designed to be adaptable, allowing for easy changes as per the construction needs. The steel frames can be dismantled, repositioned, or extended effortlessly to accommodate any alterations in the structure's design or dimensions. Moreover, the formwork panels utilized in steel frame systems are often constructed from lightweight materials like plywood or steel sheets, which can be easily cut or reshaped to meet specific requirements. This adaptability and ease of adjustment make steel frame formwork the preferred choice for construction projects that involve expected modifications or changes.

- Q: What are the safety precautions for using steel frame formwork in hazardous conditions?

- When using steel frame formwork in hazardous conditions, it is crucial to take several safety precautions. These precautions include ensuring that all personnel involved are properly trained and equipped with appropriate personal protective equipment (PPE) such as hard hats, safety glasses, gloves, and steel-toed boots. Additionally, the formwork should be inspected regularly for any signs of damage or weakness, and any defective components should be replaced immediately. Adequate fall protection systems, such as guardrails and safety nets, should be installed to prevent falls from heights. Lastly, it is important to follow all relevant safety guidelines and regulations specific to the hazardous conditions, such as those related to working in confined spaces or operating heavy machinery.

- Q: How does steel frame formwork handle the load distribution of a structure?

- A versatile and strong system utilized in construction for effective load distribution of structures is steel frame formwork. The main characteristic of this formwork is its ability to evenly distribute weight and forces on the structure, ensuring a stable and balanced load distribution. To begin with, steel frame formwork is comprised of interconnected rigid and strong steel panels capable of withstanding heavy loads. These panels are assembled and fixed together to create a framework that serves as a support system for the structure. The design of the steel frame formwork is such that it evenly distributes the load across the panels, preventing concentration of forces in specific areas. Moreover, steel frame formwork offers high customization, allowing for precise adjustment and alignment of the panels. This adaptability enables the formwork system to accommodate structures with complex geometries or irregular shapes. By ensuring accurate alignment of the panels, the load distribution is optimized, avoiding localized stress points and ensuring a uniform distribution of forces. Furthermore, steel frame formwork has a high load-bearing capacity due to the strength and durability of steel. Steel is known for its robustness and resistance to deformation, enabling it to handle heavy loads without compromising the stability of the structure. The use of steel in the formwork system ensures even and efficient load distribution, minimizing the risk of structural failure or collapse. Additionally, steel frame formwork allows for the integration of additional reinforcement elements, such as steel bars or mesh, which further enhance the load distribution capabilities of the structure. These reinforcements provide additional strength and stiffness, ensuring that the load is evenly distributed across the entire formwork system. In conclusion, steel frame formwork is an excellent solution for managing load distribution in structures. Its strength, adaptability, and high load-bearing capacity enable it to evenly distribute weight and forces on the structure, ensuring a stable and balanced load distribution. This guarantees the structural integrity and safety of the building, making steel frame formwork a popular choice in the construction industry.

- Q: What are the different types of clamping systems used with steel frame formwork?

- There are several different types of clamping systems that are commonly used with steel frame formwork. These clamping systems are designed to securely hold the formwork panels together, ensuring that they remain in place during the concrete pouring process. One type of clamping system that is commonly used is the wedge clamp system. This system consists of wedge-shaped clamps that are inserted into slots on the formwork panels. As the wedges are driven into the slots, they create a tight and secure connection between the panels, preventing any movement or shifting. Another type of clamping system is the pin and wedge system. This system uses steel pins that are inserted into pre-drilled holes in the formwork panels. Once the pins are in place, steel wedges are driven into slots on the pins, creating a strong connection between the panels. Some clamping systems use a combination of pins and clamps. These systems typically have pins that are inserted into pre-drilled holes in the formwork panels, and clamps that are tightened around the pins to hold the panels together. In addition to these clamping systems, there are also systems that use bolts and nuts, as well as systems that use hydraulic or mechanical mechanisms to hold the formwork panels together. The choice of clamping system will depend on various factors, including the size and complexity of the formwork structure, the required strength and stability, and the specific requirements of the construction project. It is important to carefully consider these factors and select the appropriate clamping system to ensure the safety and success of the formwork installation.

Send your message to us

Steel Frame Formwork of Flexible Assemble and Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords