Steel Frame Formwork with Faster and Easy Operation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

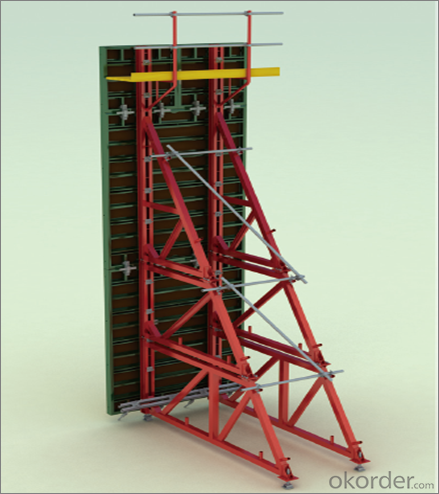

1. Structure of Steel Frame Formwork GK120

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork GK120

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

3. Steel Frame Formwork GK120 Images

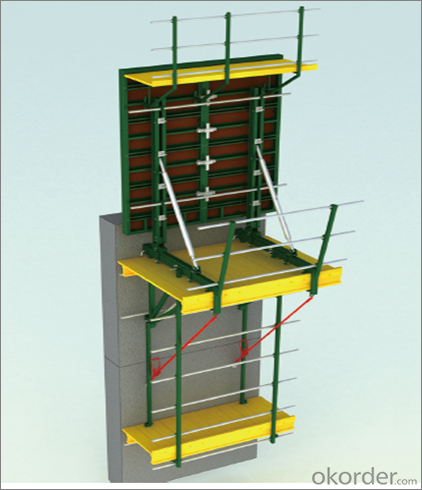

4. Steel Frame Formwork GK120 Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

-There is a prizing part designed in the corner, which can help to position and remove formwork easily.

-The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

-The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

5. FAQ of Steel Frame Formwork GK120

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel Frame Formwork GK120, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel Frame Formwork GK120, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Can steel frame formwork be used for both interior and exterior concrete elements?

- Yes, steel frame formwork can be used for both interior and exterior concrete elements. Steel frame formwork is versatile and durable, making it suitable for various types of concrete structures. Whether it is a wall, column, beam, slab, or any other concrete element, steel frame formwork can be easily adapted to meet the requirements of the project. Its strength and stability allow for the creation of smooth and precise concrete finishes, making it ideal for both interior and exterior applications. Additionally, steel frame formwork is reusable, which makes it a cost-effective choice for construction projects.

- Q: What are the different methods of leveling and adjusting steel frame formwork?

- Some of the different methods of leveling and adjusting steel frame formwork include using adjustable props, wedges, leveling screws, and hydraulic jacks. These tools and techniques help ensure that the formwork is properly aligned and supported to achieve a level and stable construction surface.

- Q: How does steel frame formwork contribute to the overall safety of a construction project?

- There are several ways in which the overall safety of a construction project is enhanced by the presence of steel frame formwork. To begin with, the use of steel frame formwork results in a highly sturdy and reliable structure that can withstand the substantial loads and pressures experienced during construction. This guarantees that the formwork remains stable and secure, thereby reducing the likelihood of collapse or accidents. Furthermore, the precision and accuracy of construction are facilitated by steel frame formwork, which is indispensable for maintaining safety standards. The formwork system is specifically designed to ensure proper alignment and support, thus ensuring that the concrete is poured in the correct location and at the appropriate level. This serves to prevent any structural flaws that could compromise the safety of the building. In addition, steel frame formwork incorporates safety features such as handrails and safety platforms, creating a secure working environment for construction workers. These features enable workers to access and work on the formwork in a safe manner, thereby reducing the risk of falls or injuries. Moreover, the use of steel frame formwork diminishes reliance on traditional timber formwork, which is susceptible to deterioration and damage over time. Steel frame formwork, on the other hand, exhibits greater resistance to wear and tear, ensuring that the formwork remains stable and safe throughout the construction process. In conclusion, steel frame formwork is an integral element in promoting a safe construction project. Its durability, precision, and safety features all contribute to the overall safety of the construction site, mitigating the risk of accidents, collapses, and injuries.

- Q: How does steel frame formwork help in reducing concrete bleeding?

- Steel frame formwork helps in reducing concrete bleeding by providing a stable and rigid structure that prevents excessive movement of the concrete during pouring and curing. This minimizes the segregation of materials and helps to evenly distribute the water content, thereby reducing the chances of bleeding.

- Q: What are the considerations for selecting the appropriate formwork spacing?

- There are several factors that need to be taken into account when choosing the appropriate formwork spacing. To begin with, the type and size of the formwork material play a significant role. Different materials have varying load-bearing capacities, so it is crucial to select a spacing that can adequately support the weight of the poured concrete. Furthermore, the size of the formwork panels also affects the spacing. Larger panels may require closer spacing to prevent sagging or bowing. The height of the formwork is another important consideration. As the height increases, the spacing between supports may need to be decreased to ensure stability and prevent excessive deflection. This is especially important in taller structures where external forces like wind can introduce additional stresses on the formwork. The concrete mix design and pouring technique should also be taken into account. If a high-slump concrete mix is used, it may exert greater pressure on the formwork, necessitating closer spacing to prevent bulging or blowouts. Likewise, if a fast-setting or self-consolidating concrete is being used, the formwork spacing must be chosen to accommodate the rapid pouring and setting process. The expected loads during the construction process must also be considered. If heavy equipment or machinery will be used near the formwork, closer spacing may be necessary to provide extra support and prevent damage. Additionally, the presence of rebar or other reinforcing elements within the concrete should be factored in, as they can increase the load on the formwork and require tighter spacing. Lastly, safety is a crucial aspect when determining formwork spacing. Sufficient spacing should be chosen to allow workers to safely access and maneuver around the formwork. This includes considering the space required for tools, equipment, and proper bracing or scaffolding. In conclusion, the selection of appropriate formwork spacing requires careful consideration of factors such as formwork material, height, concrete mix design, expected loads, and safety requirements. By taking these considerations into account, the formwork can provide the necessary support and stability for successful concrete construction.

- Q: Can steel frame formwork be used for precast wall panels?

- Yes, steel frame formwork can be used for precast wall panels. Steel frame formwork is commonly used in construction projects, including the production of precast wall panels. Steel formwork provides a strong and durable structure for casting the concrete panels and can withstand the high pressures exerted by the wet concrete during the curing process. Additionally, steel formwork allows for precise and accurate shaping of the wall panels, ensuring they meet the desired specifications and dimensions. The steel frame formwork system can be easily assembled and disassembled, making it convenient for repetitive use in mass production of precast wall panels. Overall, steel frame formwork offers numerous advantages for the production of precast wall panels, such as strength, durability, accuracy, and ease of use.

- Q: How does steel frame formwork compare to traditional wooden formwork?

- Steel frame formwork offers several advantages over traditional wooden formwork. Firstly, steel frame formwork is much more durable and long-lasting compared to wooden formwork. Steel is a strong and sturdy material that can withstand heavy loads and repeated use, whereas wood is vulnerable to damage, warping, and decay over time. This durability of steel formwork allows for multiple reuses, resulting in cost savings in the long run. Secondly, steel formwork provides greater precision and accuracy in concrete placement. The steel frames are designed to be rigid and stable, ensuring that the formwork maintains its shape and dimensions during the concrete pouring process. This accuracy is crucial in achieving a smooth and uniform concrete finish. On the other hand, wooden formwork is more prone to bending or deforming under pressure, leading to an uneven concrete surface. Additionally, steel formwork offers greater flexibility in terms of design and construction. Steel frames can be easily customized and adjusted to suit different shapes, sizes, and architectural requirements. This versatility allows for the construction of complex structures with ease. Wooden formwork, on the other hand, may require more effort and time to be modified or adapted to specific project needs. Moreover, steel formwork is more resistant to weather conditions and environmental factors. It can withstand extreme temperatures, humidity, and exposure to water without deteriorating. This resilience is especially beneficial for construction projects that are located in harsh or challenging environments. Wooden formwork, on the other hand, can be affected by moisture, leading to swelling, warping, and decreased strength. Finally, steel frame formwork is more efficient and time-saving in terms of assembly and disassembly. The standardized components of steel formwork can be easily interconnected and locked into place, reducing the need for extensive labor and manual adjustments. This efficiency translates into shorter construction cycles and increased productivity. Traditional wooden formwork, on the other hand, requires more time and effort for assembly and dismantling. In conclusion, steel frame formwork offers numerous advantages over traditional wooden formwork. Its durability, precision, flexibility, resistance to weather, and efficiency make it a preferred choice for construction projects. While wooden formwork may still have its applications in certain situations, steel formwork is increasingly becoming the preferred choice for its long-term cost savings and superior performance.

- Q: Are there any restrictions on the thickness of the concrete that can be poured using steel frame formwork?

- Concrete poured using steel frame formwork is subject to certain restrictions on thickness. The maximum thickness achievable depends on the design and load-bearing capacity of the formwork system. Typically, steel frame formwork is capable of handling relatively thick concrete sections, ranging from 200mm to 600mm in thickness. However, it is important to refer to the manufacturer's guidelines or engineering specifications to ascertain the specific limitations of the steel frame formwork being employed. Exceeding the recommended maximum thickness can strain the formwork system excessively, potentially resulting in structural failure or compromising the concrete's quality. It is crucial to ensure that the formwork can adequately support the weight and pressure exerted by the concrete during pouring, curing, and subsequent loading. In instances where thicker concrete sections are necessary, alternative formwork systems such as heavy-duty steel frames, adjustable props, or specialized shoring systems may be required. These systems are specially designed to handle higher loads and provide greater stability for pouring thicker concrete sections. Ultimately, it is vital to adhere to the manufacturer's guidelines and seek advice from a qualified engineer to determine the appropriate formwork system and its limitations for pouring concrete of a particular thickness.

- Q: Can steel frame formwork be used in projects with restricted working hours?

- Yes, steel frame formwork can be used in projects with restricted working hours. Steel frame formwork is a durable and versatile system that can be quickly assembled and disassembled, allowing for efficient construction even with limited working hours. The steel frames provide structural support and can be easily adjusted to accommodate various shapes and sizes of concrete structures. Additionally, steel frame formwork is highly reusable, reducing the need for excessive construction materials and therefore minimizing the time required for formwork installation. Overall, steel frame formwork is a suitable solution for projects with restricted working hours, as it offers flexibility, efficiency, and durability.

- Q: How does steel frame formwork improve the quality of concrete?

- Steel frame formwork improves the quality of concrete in several ways. Firstly, steel frame formwork provides a stable and rigid structure for pouring concrete, ensuring that it maintains its shape and form during the curing process. This helps to prevent any deformation or warping of the concrete, resulting in a more accurate and precise final product. Secondly, the steel frame formwork allows for the easy and efficient placement of reinforcement bars within the concrete. This is crucial for enhancing the structural integrity and strength of the concrete. The steel frame provides a secure framework for positioning and holding the reinforcement bars in place, preventing any displacement or movement during the pouring and curing process. Additionally, steel frame formwork allows for the precise control of concrete pouring, ensuring a consistent and uniform distribution of the concrete mixture. This helps to eliminate any voids or air pockets in the concrete, resulting in a more dense and durable final product. Moreover, steel frame formwork provides a smooth and even surface for the concrete, minimizing the need for additional finishing or surface treatments. This can save time and resources, while also improving the overall aesthetics of the concrete. Overall, steel frame formwork plays a vital role in improving the quality of concrete by providing stability, facilitating the placement of reinforcement bars, allowing for precise pouring, and creating a smooth surface finish.

Send your message to us

Steel Frame Formwork with Faster and Easy Operation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches