Adjustable Aluminum Formwork For Rectangle

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

Custom SF63 Rectangle / Square

Column / Wall Construction

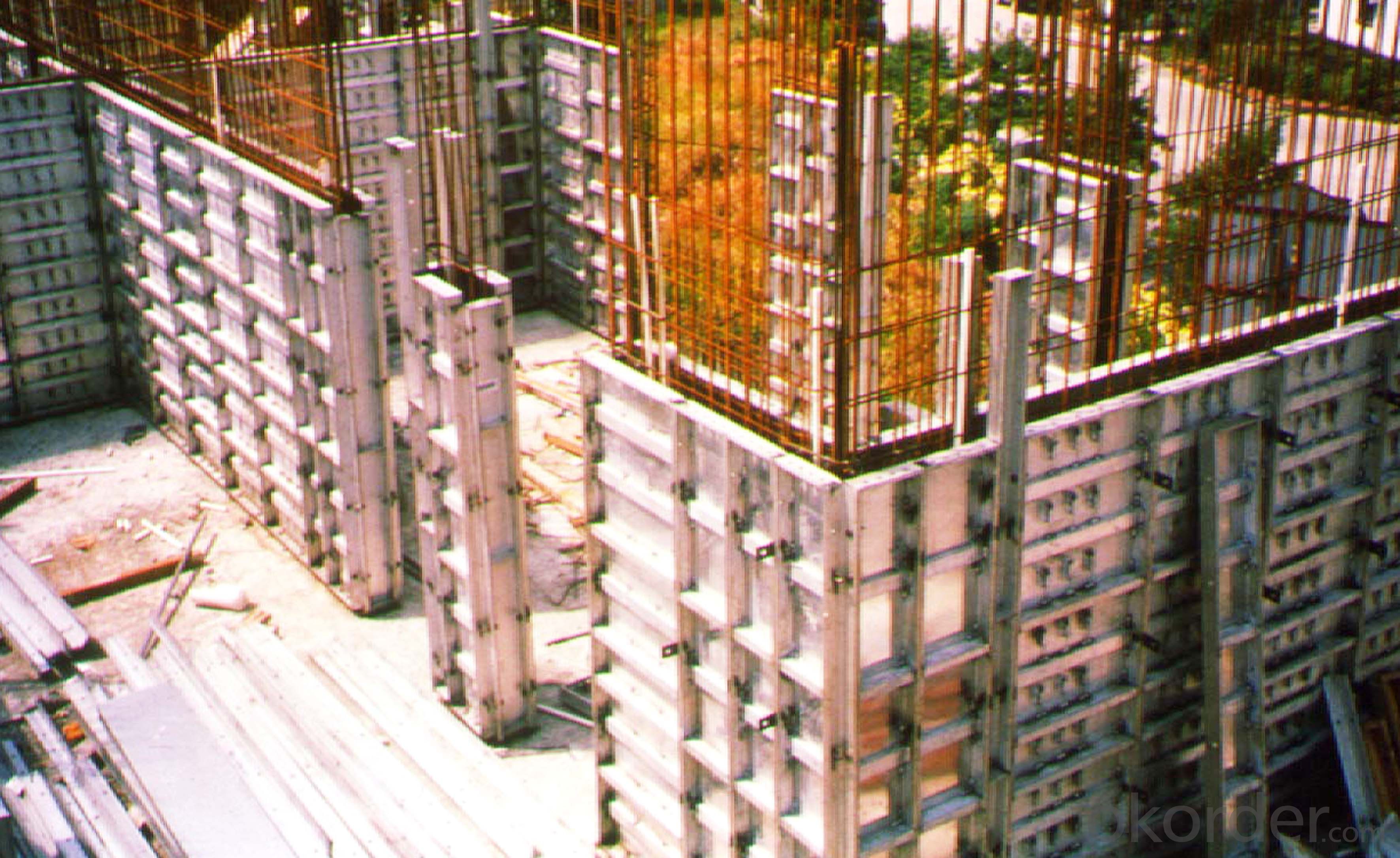

Adjustable Aluminum Formwork For Rectangle / Square Concrete Column

Description:

The whole system is made from aluminum materials. As the picture shown, every formwork unit is formed by CNBM production line. There are three special customized section bars form our standardization manufacture, and every formwork unit is welded by Robot.

AL 65 is a complete system with a full set of accessories, and can be set up flexibly according to project.

Competitive Advantage:

1. Lighter weight but high bearing capacity.

The allowable pressure from fresh concrete is 60KN/m2 with the thickness of 65mm.

2. Manual transportation can be achieved, greatly reduces the aggregate cost.

3. Perfect design, excellent produce and well welding make sure the flatness of concrete surface.

4. It is with the advantages of standard design, excellent applicability and interchangeable.

5. Simple, safe and fast.

6. No rust corrosion, easy maintenance, and high turnover rate.

Applications:

- Q: What types of concrete structures can be formed using steel frame formwork?

- Steel frame formwork is a versatile construction technique that can be employed to create various types of concrete structures. Some of the common applications of steel frame formwork include: 1. High-rise buildings: Steel frame formwork is ideal for constructing tall buildings due to its exceptional strength and stability. It offers the necessary support to pour concrete at significant heights, ensuring the structural integrity of the building. 2. Bridges and flyovers: Steel frame formwork is widely used in the construction of bridges and flyovers. It provides a robust framework that can withstand heavy loads and allows for the creation of complex shapes and curves required in these structures. 3. Industrial structures: Steel frame formwork is commonly used in the construction of industrial buildings such as factories, warehouses, and manufacturing plants. Its durability and flexibility make it suitable for accommodating large open spaces and heavy machinery. 4. Retaining walls: Steel frame formwork is an excellent choice for constructing retaining walls. It provides a strong and rigid structure that can withstand the pressure exerted by the retained soil, ensuring the stability of the wall. 5. Water tanks and reservoirs: Steel frame formwork is often employed in the construction of water tanks and reservoirs. Its ability to create watertight structures makes it suitable for storing water, ensuring there are no leaks or seepages. 6. Tunnels and underground structures: Steel frame formwork is used in the construction of tunnels and underground structures due to its ability to withstand high pressure and provide a secure framework for pouring concrete. 7. Infrastructure projects: Steel frame formwork is widely utilized in infrastructure projects such as highways, railways, and airports. It enables the construction of sturdy and durable structures that can withstand heavy traffic and adverse weather conditions. In summary, steel frame formwork can be employed to create a wide range of concrete structures, including high-rise buildings, bridges, industrial buildings, retaining walls, water tanks, tunnels, and infrastructure projects. Its strength, stability, and flexibility make it a preferred choice for many construction applications.

- Q: Are there any disadvantages to using steel frame formwork?

- There are indeed a few drawbacks to utilizing steel frame formwork. To begin with, in comparison to alternative formwork types like timber or aluminum, steel frame formwork tends to be more expensive. This can dissuade smaller construction projects or those with limited budgets. Furthermore, due to its relatively heavy nature, steel frame formwork necessitates machinery or additional manpower for handling and installation. This can result in increased overall construction time and costs. In addition, steel frame formwork lacks the flexibility of other formwork types. It is typically prefabricated to meet specific project requirements, making it less easily adjustable or adaptable to changes in design or dimensions. Lastly, regular maintenance and proper storage are necessary to prevent rust and corrosion of steel frame formwork. If not properly maintained, the formwork may deteriorate over time, posing safety risks and requiring expensive repairs or replacement. Despite these drawbacks, steel frame formwork offers numerous advantages such as high strength, durability, and reusability. As a result, it is commonly employed in large-scale construction projects where the benefits outweigh the drawbacks.

- Q: Does steel frame formwork require any specific training for installation?

- Installation of steel frame formwork requires specific training. This complex system involves precise assembling and installation processes, making it crucial for installers to possess the necessary knowledge and skills to ensure safety and effectiveness. Training for steel frame formwork installation typically includes learning how to interpret technical drawings and specifications, as well as familiarizing oneself with the various components and materials used in the formwork system. Installers are taught proper handling, lifting, and positioning techniques for steel frames, as well as the correct methods for connecting and securing formwork panels and accessories. Moreover, training encompasses important safety procedures and measures that must be followed during installation, such as wearing personal protective equipment and ensuring the stability and structural integrity of the formwork. Understanding the load capacities and limitations of the steel frame formwork system is also crucial to avoid potential accidents or structural failures. In conclusion, specific training for steel frame formwork installation is indispensable. It guarantees correct installation, compliance with standards and specifications, and provides a safe and stable support for concrete construction projects.

- Q: What are the different types of edge protection systems used with steel frame formwork?

- To ensure the safety of workers and prevent falls or accidents, various edge protection systems can be utilized in conjunction with steel frame formwork. These systems are specifically designed to establish a secure working environment by creating a barrier or guardrail around the edges of the formwork. Among the commonly employed edge protection systems for steel frame formwork is the handrail system. This particular system comprises metal or plastic handrails that are affixed to the formwork's frame. Serving as an effective barrier, these handrails effectively safeguard workers from inadvertent falls. Handrail systems are known for their simplicity in installation and flexibility to adapt to diverse formwork configurations. Another type of edge protection system is the toe board system. These horizontal barriers are installed along the lower edge of the formwork to prevent the occurrence of tools, materials, or debris falling off and potentially endangering workers below. Typically manufactured from metal or wood, toe boards can be effortlessly attached to the formwork's frame. Furthermore, certain edge protection systems incorporate mesh panels or safety nets. These systems establish a physical barrier around the perimeters of the formwork, effectively preventing accidental falls. Constructed with robust and durable materials, mesh panels or safety nets are firmly fastened to the formwork's frame. Their installation and removal are easily manageable as per the project's requirements. Finally, comprehensive edge protection systems encompass a combination of handrails, toe boards, and mesh panels or safety nets. These all-inclusive systems offer multiple layers of protection, often employed in larger construction projects or areas where risks of falls or accidents are heightened. In summary, the various types of edge protection systems utilized with steel frame formwork share the common objective of ensuring worker safety and preventing falls or accidents. The specific system employed will be contingent upon the project's demands and the level of protection necessary.

- Q: What are the transportation and logistics considerations for steel frame formwork?

- Transportation and logistics considerations for steel frame formwork include the weight and size of the frames, the availability of appropriate transportation vehicles, the need for proper handling and securing during transit to prevent damage, and the coordination and planning of delivery routes and schedules to ensure timely and efficient delivery to construction sites.

- Q: Can steel frame formwork be used for architectural and artistic projects?

- Yes, steel frame formwork can be used for architectural and artistic projects. Its strength and durability make it suitable for creating complex and intricate designs, and it can be customized to meet specific project requirements. Additionally, steel frame formwork provides stability and precision, ensuring high-quality finishes in architectural and artistic constructions.

- Q: Can steel frame formwork be easily integrated with building automation systems?

- Steel frame formwork lends itself well to integration with building automation systems. These systems are specifically designed to regulate and oversee various building functions, including lighting, heating, ventilation, and security. Conversely, steel frame formwork is a construction method that employs steel frames to support concrete during the construction phase. The integration of steel frame formwork with building automation systems offers multiple benefits. Firstly, it enables improved control and monitoring of the construction process. By connecting the steel frame formwork to the building automation system, construction managers can remotely supervise construction progress, monitor concrete pouring, and ensure proper formwork installation. Secondly, integrating steel frame formwork with building automation systems enhances safety and efficiency on the construction site. The building automation system can be programmed to automatically adjust the formwork's position and alignment, thereby reducing the risk of errors and accidents. Furthermore, it can provide real-time data on the formwork's load-bearing capacity, ensuring that it remains within safe limits and upholds the structural integrity of the building. Furthermore, the integration of steel frame formwork with building automation systems contributes to the sustainability of the construction process. The automation system optimizes the utilization of resources, such as energy and materials, by adjusting the formwork's position and timing of concrete pouring. This optimization leads to significant cost savings and minimizes waste. In conclusion, integrating steel frame formwork with building automation systems brings numerous advantages in terms of control, safety, efficiency, and sustainability. By combining these technologies, construction projects can be executed more effectively and yield higher-quality outcomes.

- Q: Can steel frame formwork be used for both horizontal and vertical applications?

- Yes, steel frame formwork can be used for both horizontal and vertical applications. Its sturdy construction and adjustable features make it suitable for various types of concrete structures, allowing for efficient and flexible formwork solutions.

- Q: How does steel frame formwork address issues of concrete shrinkage and expansion?

- The construction technique known as steel frame formwork effectively solves the problems of concrete shrinkage and expansion. One reason for this is steel's high tensile strength, which allows it to withstand the forces exerted by concrete during the shrinkage and expansion process. As a result, the concrete structure remains undamaged and free from cracks. Furthermore, steel frame formwork offers a rigid and stable framework for pouring concrete. This ensures that the concrete is evenly distributed and properly supported, minimizing the risk of uneven shrinkage or expansion. The steel frame also acts as a barrier, preventing the concrete from expanding beyond its intended dimensions. In addition, steel frame formwork allows for the use of expansion joints. These joints are strategically placed within the formwork to accommodate the natural movements of the concrete caused by temperature changes and moisture variations. By incorporating these expansion joints, the steel frame formwork enables the concrete to shrink and expand without causing any structural issues or damage. Moreover, steel frame formwork can be easily adjusted and modified to accommodate changes in concrete dimensions due to shrinkage or expansion. This flexibility allows for necessary adjustments to be made during the construction process, ensuring a precise and accurate final product. In summary, steel frame formwork effectively addresses the issues of concrete shrinkage and expansion by providing a strong and stable framework, incorporating expansion joints, and allowing for easy adjustments. By utilizing this construction technique, the concrete structure remains intact and unharmed by these natural processes.

- Q: How does steel frame formwork handle different types of formwork stripping equipment?

- Steel frame formwork offers versatility and durability, effortlessly handling various types of formwork stripping equipment. The steel frames, designed for stability and support, can easily accommodate mechanical or hydraulic systems for stripping. An advantage of steel frame formwork is its ability to withstand the high pressure and force exerted during the stripping process. This is crucial when using different stripping equipment, as a robust support system is necessary for safe and efficient formwork removal. The steel frames are engineered to provide a stable and secure platform for the stripping equipment, ensuring proper alignment and compatibility with various stripping tools. This guarantees secure attachment, enabling effective and efficient formwork removal. Additionally, steel frame formwork is highly adaptable, making it suitable for use with different types of formwork stripping equipment. Whether relying on mechanical force or hydraulic power, the steel frames seamlessly accommodate and work with these diverse equipment options. In conclusion, steel frame formwork is specifically designed to handle various types of formwork stripping equipment. Its strength, stability, and adaptability make it an ideal choice for construction projects requiring efficient and safe formwork removal.

Send your message to us

Adjustable Aluminum Formwork For Rectangle

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords