Light Steel Frame Formwork with Plastic Plywood

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

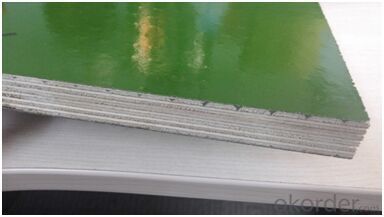

1. Structure of Light Steel Frame Formwork with Plastic Plywood

Light steel frame formwork is constructed with two different plywood as frames-wood plywood and plastic plywood. The light frame formwork with Plastic plywood more and more popular in construction industry.

2. Main Features of Light Steel Frame Formwork with Plastic Plywood

-High quality of plastic plywood can stay solid with more than 7 hours in boiled water.

-Frame of plywood is made of plastic as well

-Repeated use of more than 20 times

-PP material used

-Plywood is used inside

3. Light Steel Frame Formwork with Plastic plywood images

4. Light Steel Frame Formwork Specifications

5. FAQ of Light Steel Frame Formwork with Plastic plywood

1) What can we do for you?

.We can ensure the quality of the Light Steel Frame Formwork with Plastic Plywood and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: What are the different types of edge protection systems used with steel frame formwork for bridge construction?

- There are several types of edge protection systems that are commonly used with steel frame formwork for bridge construction. These systems are designed to ensure the safety of workers and prevent accidents during construction. One type of edge protection system is the guardrail system. This system consists of metal or plastic guardrails that are installed along the edges of the formwork to provide a physical barrier between workers and the edge of the bridge. Guardrail systems are often adjustable, allowing for easy installation and removal as the construction progresses. Another type of edge protection system is the safety net system. Safety nets are typically made of strong nylon or polypropylene material and are installed below the formwork to catch falling objects or workers. These nets are designed to absorb the impact and prevent serious injuries in case of a fall. In addition to guardrail and safety net systems, some bridge construction projects may also utilize toe boards. Toe boards are horizontal boards that are installed at the base of the formwork to prevent tools, equipment, or materials from falling off the edge of the bridge. Toe boards are often made of wood or metal and are securely attached to the formwork to provide a sturdy barrier. Finally, some edge protection systems may include personal protective equipment (PPE) such as safety harnesses and lifelines. These systems are typically used in conjunction with guardrails or safety nets to provide an additional layer of protection for workers who may need to access the edge of the bridge during construction. Safety harnesses and lifelines are designed to prevent falls and allow workers to safely move about the construction site. Overall, the different types of edge protection systems used with steel frame formwork for bridge construction are designed to enhance the safety of workers and prevent accidents. The specific type of system used will depend on the requirements of the project and the regulations in place.

- Q: Are steel frame formwork systems adjustable?

- Indeed, steel frame formwork systems possess the capability to be adjusted. These systems have been meticulously engineered to exhibit flexibility and adaptability to cater to diverse construction projects and demands. Typically crafted from top-notch steel, the frames ensure robustness and stability while allowing for alterations in both height and width. Moreover, certain steel frame formwork systems incorporate adjustable elements like telescopic beams, adjustable props, and brackets, which further augment their adaptability. This remarkable adjustability empowers contractors to effortlessly tailor the formwork to accommodate an array of concrete structures with varying shapes and sizes. All in all, steel frame formwork systems present a versatile and adjustable solution for construction endeavors.

- Q: Can steel frame formwork be used in projects with tight construction schedules?

- Yes, steel frame formwork can be used in projects with tight construction schedules. Steel frame formwork is known for its strength, durability, and ability to withstand high pressure and repetitive use. Its quick assembly and disassembly process allows for faster construction cycles, making it a suitable choice for projects with tight schedules. Additionally, the versatility of steel frame formwork allows it to be used in various types of construction projects, further contributing to its effectiveness in meeting tight deadlines.

- Q: Can steel frame formwork be used for architectural concrete structures?

- Yes, steel frame formwork can be used for architectural concrete structures. Steel frame formwork is a versatile and durable option that offers several advantages for architectural concrete construction. One of the key benefits of steel frame formwork is its strength and stability. Steel is a strong material that can withstand the pressure exerted by fresh concrete during the pouring and curing process. This allows for the construction of complex architectural concrete structures that require intricate designs and shapes. Additionally, steel frame formwork provides excellent dimensional accuracy, ensuring that the final concrete structure meets the architectural specifications. The steel frames are designed to be easily adjustable, allowing for precise control over the formwork dimensions and ensuring a high level of accuracy in the finished product. Moreover, steel frame formwork is reusable, making it a cost-effective option for architectural concrete construction. The frames can be easily dismantled and reassembled for use in future projects, reducing the need for new formwork materials and minimizing waste. Furthermore, steel frame formwork offers flexibility in terms of customization. The frames can be fabricated to match the specific architectural requirements, allowing for the creation of unique and visually appealing concrete structures. This makes steel frame formwork an ideal choice for architectural projects where aesthetics are a major consideration. In conclusion, steel frame formwork can indeed be used for architectural concrete structures. Its strength, stability, dimensional accuracy, reusability, and customization options make it a reliable and efficient choice for creating visually stunning architectural concrete designs.

- Q: How does steel frame formwork contribute to the overall safety of a construction project?

- Steel frame formwork contributes to the overall safety of a construction project in several ways. Firstly, steel frame formwork provides a highly durable and reliable structure that can withstand the heavy loads and pressures experienced during the construction process. This ensures that the formwork remains stable and secure, reducing the risk of collapse or accidents. Additionally, steel frame formwork allows for precise and accurate construction, which is essential for maintaining safety standards. The formwork system is designed to provide proper alignment and support, ensuring that the concrete is poured in the right place and at the right level. This helps prevent any structural defects that could compromise the safety of the building. Moreover, steel frame formwork is designed with safety features such as handrails and safety platforms, which provide a secure working environment for construction workers. These features enable workers to access and work on the formwork safely, reducing the risk of falls or injuries. Furthermore, the use of steel frame formwork reduces the reliance on traditional timber formwork, which can be prone to deterioration and damage over time. Steel frame formwork is more resistant to wear and tear, ensuring that the formwork remains stable and safe throughout the construction process. Overall, steel frame formwork is an essential component of a safe construction project. Its durability, accuracy, and safety features contribute to the overall safety of the construction site, reducing the risk of accidents, collapses, and injuries.

- Q: What is the maximum permissible deflection of steel frame formwork panels?

- The maximum permissible deflection of steel frame formwork panels is typically specified by the manufacturer and can vary depending on the specific design and application. It is essential to consult the manufacturer's guidelines or industry standards to determine the exact maximum permissible deflection for a particular steel frame formwork panel.

- Q: Are there any specific design considerations for steel frame formwork?

- Steel frame formwork has several important design considerations. Firstly, it is crucial to ensure that the steel frame is sufficiently strong and rigid to support the weight of the concrete. This entails determining the appropriate size and dimensions of the steel members, as well as the spacing and arrangement of the supports. Another key consideration is the ease of assembly and disassembly of the formwork. It is important to design the steel frame formwork in a manner that allows for quick and efficient installation and removal. This can have a significant impact on the overall construction timeline and cost. Additionally, the design should take into account potential lateral forces, such as wind or concrete pressure. It is essential to adequately brace and support the steel frame formwork to resist these forces. This may involve incorporating diagonal bracing or tie rods to enhance stability and prevent deformation of the formwork. Deflection of the formwork is another issue that needs to be addressed in the design. Steel frames have a tendency to deflect under the weight of the concrete, which can result in uneven surfaces or dimensional inaccuracies. To mitigate this, the formwork should be designed with sufficient stiffness and rigidity to minimize deflection and maintain the desired shape and dimensions of the concrete elements. Furthermore, the design should consider the reusability of the steel frame formwork. Steel is a durable material, and well-designed formwork can be used for multiple construction cycles, reducing waste and overall project costs. This requires careful attention to material selection, surface treatment, and the overall durability of the formwork components. In conclusion, specific design considerations for steel frame formwork include strength and rigidity, ease of assembly and disassembly, resistance to lateral forces, prevention of formwork deflection, and reusability. A well-designed steel frame formwork system can contribute to efficient and cost-effective construction processes.

- Q: What are the different types of formwork accessories used with steel frame formwork systems?

- Some common types of formwork accessories used with steel frame formwork systems include form ties, form anchors, tie rods, braces, clamps, wedges, and scaffolding. These accessories are essential for ensuring the stability and proper alignment of the formwork during the concrete pouring process.

- Q: How does steel frame formwork handle the placement of MEP (mechanical, electrical, plumbing) systems within the concrete structure?

- Steel frame formwork is a versatile and efficient system that can easily handle the placement of MEP systems within a concrete structure. The steel frames provide a sturdy and reliable support structure that allows for the seamless integration of MEP components. One of the key advantages of steel frame formwork is its adaptability. The frames can be easily modified and customized to accommodate the specific requirements of MEP systems. This includes creating openings and penetrations for pipes, conduits, ducts, and other essential components. The flexibility of steel frame formwork ensures that MEP systems can be efficiently incorporated into the concrete structure without compromising its integrity. Additionally, steel frame formwork offers excellent load-bearing capabilities. This is crucial when considering the weight and potential vibrations associated with MEP systems. The strong and durable nature of the steel frames ensures that they can withstand the weight and movement of MEP components, providing a stable and secure platform for their installation. Furthermore, steel frame formwork allows for precise and accurate placement of MEP systems. The frames can be easily aligned and leveled, ensuring that the MEP components are installed with precision. This is particularly important in complex MEP installations, where accuracy is crucial to avoid clashes or conflicts between different systems. Moreover, steel frame formwork simplifies the installation and maintenance of MEP systems. The frames provide easy access to the MEP components, allowing for convenient installation, inspection, and maintenance. This accessibility ensures that any repairs or modifications can be carried out efficiently, reducing downtime and minimizing disruptions to the concrete structure. In summary, steel frame formwork is a highly efficient and effective system for handling the placement of MEP systems within a concrete structure. Its adaptability, load-bearing capabilities, precision, and accessibility make it an ideal choice for integrating MEP components seamlessly into the construction process.

- Q: Can steel frame formwork be customized to fit specific project requirements?

- Yes, steel frame formwork can be customized to fit specific project requirements. Steel frame formwork offers flexibility in terms of size, shape, and design, allowing it to be tailored to meet the specific needs of a construction project. This customization ensures that the formwork accurately matches the project's unique requirements, facilitating efficient and precise construction.

Send your message to us

Light Steel Frame Formwork with Plastic Plywood

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords