Steel Frame Formworks in China Market for Building Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel Frame Formwork

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

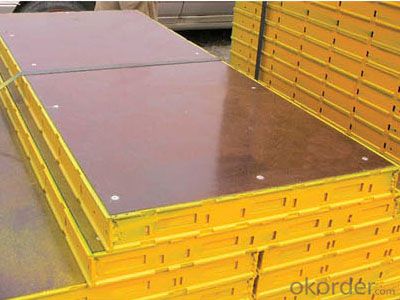

3. Steel Frame Formwork Images

4. Steel Frame Formwork GK120 Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

-There is a prizing part designed in the corner, which can help to position and remove formwork easily.

-The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

-The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

5. FAQ of Steel Frame Formwork GK120

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel Frame Formwork GK120, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel Frame Formwork GK120, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: How does steel frame formwork contribute to the overall cost-effectiveness of a construction project?

- The cost-effectiveness of a construction project is enhanced by steel frame formwork in several ways. Firstly, the durability and longevity of steel allow for multiple reuses of the formwork, significantly reducing the need for frequent replacement. This results in substantial savings on formwork materials throughout the project's lifespan. Moreover, the high versatility of steel frame formwork enables easy adjustments and customization to meet specific project requirements. This flexibility facilitates efficient and accurate construction, reducing the time and effort needed for formwork installation and removal. As a result, labor costs are reduced, and construction schedules can be expedited, leading to overall cost savings. Furthermore, steel frame formwork ensures excellent stability and structural integrity, guaranteeing even and precise pouring of concrete. This minimizes errors and the need for rework, thereby reducing material wastage and associated costs. The precision and consistency provided by steel frame formwork also enhance the overall quality of the construction, reducing the need for future repairs or maintenance. Additionally, steel frame formwork is cost-effective due to its ease of transportation and assembly. The lightweight nature of steel components allows for easy transportation to the construction site, resulting in reduced transportation costs. Furthermore, the assembly process is straightforward, enabling quick setup and dismantling of the formwork, saving time and labor expenses. Lastly, steel frame formwork offers a high level of safety and stability during the construction process. The robustness of steel ensures that the formwork can withstand heavy loads and adverse weather conditions, minimizing the risk of accidents or delays. This not only protects workers but also avoids potential financial liabilities and disruptions to the project. In conclusion, the utilization of steel frame formwork in construction projects greatly enhances cost-effectiveness. Its durability, versatility, precision, ease of transportation, and safety features all contribute to reduced expenses on materials, labor, and maintenance. Through optimized construction timelines and minimized errors, steel frame formwork helps optimize project budgets and achieve successful outcomes.

- Q: Can steel frame formwork be used for both cast-in-place and post-tensioned concrete construction?

- Yes, steel frame formwork can be used for both cast-in-place and post-tensioned concrete construction. Steel frame formwork is a versatile system that provides the necessary support and containment for poured concrete during construction. It consists of steel panels, adjustable props, and other accessories that can be assembled and disassembled easily to suit different construction needs. For cast-in-place concrete construction, steel frame formwork is commonly used to create the desired shape and dimensions of the concrete structure. The steel panels can be adjusted to form walls, columns, beams, and slabs, allowing for flexibility in design. The formwork system ensures that the concrete is poured and cured properly, resulting in a high-quality finished product. In post-tensioned concrete construction, steel frame formwork is also widely utilized. Post-tensioning is a technique where steel cables or tendons are tensioned after the concrete has been poured and cured. The steel frame formwork provides the necessary support and containment for the concrete during the tensioning process. It ensures that the tendons are properly positioned and protected while the concrete is being stressed. Overall, steel frame formwork is a suitable choice for both cast-in-place and post-tensioned concrete construction. Its versatility, strength, and adaptability make it a reliable system for creating various types of concrete structures.

- Q: Can steel frame formwork be used for both single-sided and double-sided concrete pouring?

- Yes, steel frame formwork can be used for both single-sided and double-sided concrete pouring. Steel frame formwork is versatile and can be easily adjusted and assembled to accommodate different pouring requirements. For single-sided concrete pouring, the formwork is positioned on one side of the structure, while for double-sided pouring, the formwork is positioned on both sides. The steel frame formwork provides the necessary support and stability to contain the concrete and ensure it sets properly. Additionally, steel frame formwork is durable and can withstand the pressure exerted by the concrete, making it suitable for both types of pouring.

- Q: Are there any specific considerations for using steel frame formwork in coastal areas?

- Yes, there are several specific considerations that need to be taken into account when using steel frame formwork in coastal areas: 1. Corrosion resistance: Coastal areas are prone to high levels of humidity, saltwater exposure, and corrosive environments. Therefore, it is crucial to use steel frames that have high corrosion resistance, such as galvanized or stainless steel. This will ensure the longevity and durability of the formwork system. 2. Material selection: The choice of materials for formwork should be carefully considered for coastal areas. It is important to select materials that can withstand the harsh coastal environment, including saltwater, wind, and sand. Steel frames are a suitable choice due to their strength and resistance to corrosion. 3. Maintenance: Regular maintenance is essential to prevent corrosion and ensure the longevity of steel frame formwork in coastal areas. This includes routine inspections, cleaning, and reapplication of protective coatings as necessary. Proper maintenance will help to extend the lifespan of the formwork system and prevent any potential safety hazards. 4. Anchoring and stability: Coastal areas often experience strong winds and storms, which can put additional loads and stresses on the formwork system. It is crucial to ensure that the steel frames are properly anchored and secured to withstand these forces. Additionally, the formwork system should be designed to have adequate stability and resistance against lateral loads, such as wind or wave action. 5. Environmental considerations: Coastal areas are often environmentally sensitive, with ecosystems that need to be protected. When using steel frame formwork, it is important to consider the impact on the surrounding environment. Measures should be taken to prevent any potential pollution or contamination during the construction process, such as using environmentally friendly coatings or sealants. Overall, while steel frame formwork can be used in coastal areas, it is essential to consider the specific challenges posed by the coastal environment. By selecting the right materials, implementing proper maintenance practices, ensuring stability and anchoring, and considering environmental factors, steel frame formwork can be effectively used in coastal construction projects.

- Q: Can steel frame formwork be used for both horizontal and vertical formwork applications?

- Yes, steel frame formwork can be used for both horizontal and vertical formwork applications. Steel frame formwork is a versatile and robust system that can be easily assembled and adjusted to suit various shapes, sizes, and heights of concrete elements. It is commonly used in construction projects for forming walls, columns, beams, slabs, and other structural elements. The steel frame formwork provides excellent stability and support, making it suitable for both vertical and horizontal applications. Additionally, steel frame formwork offers high load-bearing capacity, durability, and reusability, making it a cost-effective choice for formwork in construction projects.

- Q: How does steel frame formwork prevent the formation of concrete bleeding or excess water accumulation?

- By providing a sturdy structure, steel frame formwork effectively prevents the occurrence of concrete bleeding or the build-up of excess water. This is achieved by firmly holding the formwork panels in place, thus eliminating any potential movement or deformation during the pouring and curing process of the concrete. The design of the steel frame formwork focuses on creating tight joints and connections, leaving no room for any gaps or openings where excess water could escape or collect. This effectively prevents water bleeding from the concrete, which can compromise the structural integrity and cause surface defects. Furthermore, the high-quality materials used in the construction of steel frame formwork are resistant to water absorption. This prevents the formwork from absorbing any excess water from the concrete, which could result in an uncontrolled increase in the water-cement ratio and ultimately weaken the strength and durability of the concrete. To further enhance its performance, steel frame formwork is often coated with a layer of anti-adhesive material, such as oil or wax. This coating prevents the concrete from sticking to the formwork surface, reducing friction and minimizing the risk of water accumulation. In summary, the secure and watertight enclosure provided by the rigid and tightly constructed steel frame formwork effectively prevents concrete bleeding and excess water accumulation. This ensures the quality and durability of the concrete structure, leading to a long-lasting and resilient construction.

- Q: What is the maximum height that can be achieved using steel frame formwork?

- The maximum height that can be achieved using steel frame formwork depends on various factors such as the design and quality of the formwork system, the structural stability of the building, and the expertise of the construction team. However, generally speaking, steel frame formwork has the potential to reach considerable heights. With proper engineering and construction techniques, it is possible to construct high-rise buildings using steel frame formwork systems. In fact, steel frame formwork is commonly used in the construction of tall structures and skyscrapers worldwide. The specific maximum height achievable would be determined by a range of factors including the local building codes and regulations, the load-bearing capacity of the steel frame formwork, and the overall structural design of the building.

- Q: Can steel frame formwork be adjusted to accommodate different dimensions?

- Steel frame formwork is capable of being adjusted to accommodate a range of dimensions. One of the benefits of utilizing steel frame formwork is its ability to be flexible and adaptable to different construction projects. The steel frames can be easily altered by the addition or removal of panels, adjustments to the height, or changes to the configuration, all of which can be tailored to suit the various dimensions and shapes of concrete structures. This adjustability characteristic allows for the efficient and effective utilization of the formwork system, resulting in time and cost savings during the construction process. Furthermore, the strength and durability of steel ensure stability and structural integrity, making it a dependable choice for accommodating various dimensions in formwork applications.

- Q: How does steel frame formwork contribute to the overall efficiency of concrete placement and compaction?

- Steel frame formwork contributes to the overall efficiency of concrete placement and compaction in several ways. Firstly, steel frame formwork provides a stable and rigid structure that helps to maintain the shape and dimensions of the concrete elements being formed. This ensures accurate and precise placement of the concrete, resulting in a more efficient construction process. The steel frames are designed to withstand the pressure exerted by the wet concrete, preventing any deformation and maintaining the desired shape of the structure. Secondly, steel frame formwork allows for easy and quick assembly and disassembly. The frames are usually prefabricated and can be easily transported and assembled on-site. This saves time and labor, making the construction process more efficient. Additionally, steel frame formwork can be reused multiple times, further reducing the overall time and cost of the project. Furthermore, steel frame formwork provides a smooth and even surface for concrete compaction. The rigid structure of the steel frames prevents any bulging or sagging of the formwork, ensuring that the concrete is evenly distributed and compacted. This results in a higher quality finish and reduces the need for additional compaction efforts, saving time and resources. Lastly, steel frame formwork allows for easy access to the concrete during the placement and compaction process. The frames can be designed with openings and access points, providing convenient access for workers and equipment. This facilitates efficient pouring and compaction, as workers can easily reach all areas of the formwork, ensuring proper consolidation and eliminating the risk of voids or weak spots in the concrete. In conclusion, steel frame formwork significantly contributes to the overall efficiency of concrete placement and compaction. It provides stability, accuracy, reusability, and easy access, resulting in a more streamlined construction process and a higher quality finished product.

- Q: Are there any specific design considerations for steel frame formwork?

- Steel frame formwork has several important design considerations. Firstly, it is crucial to ensure that the steel frame is sufficiently strong and rigid to support the weight of the concrete. This entails determining the appropriate size and dimensions of the steel members, as well as the spacing and arrangement of the supports. Another key consideration is the ease of assembly and disassembly of the formwork. It is important to design the steel frame formwork in a manner that allows for quick and efficient installation and removal. This can have a significant impact on the overall construction timeline and cost. Additionally, the design should take into account potential lateral forces, such as wind or concrete pressure. It is essential to adequately brace and support the steel frame formwork to resist these forces. This may involve incorporating diagonal bracing or tie rods to enhance stability and prevent deformation of the formwork. Deflection of the formwork is another issue that needs to be addressed in the design. Steel frames have a tendency to deflect under the weight of the concrete, which can result in uneven surfaces or dimensional inaccuracies. To mitigate this, the formwork should be designed with sufficient stiffness and rigidity to minimize deflection and maintain the desired shape and dimensions of the concrete elements. Furthermore, the design should consider the reusability of the steel frame formwork. Steel is a durable material, and well-designed formwork can be used for multiple construction cycles, reducing waste and overall project costs. This requires careful attention to material selection, surface treatment, and the overall durability of the formwork components. In conclusion, specific design considerations for steel frame formwork include strength and rigidity, ease of assembly and disassembly, resistance to lateral forces, prevention of formwork deflection, and reusability. A well-designed steel frame formwork system can contribute to efficient and cost-effective construction processes.

Send your message to us

Steel Frame Formworks in China Market for Building Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches