Steel Frame Formwork for Constrction with High standardized System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

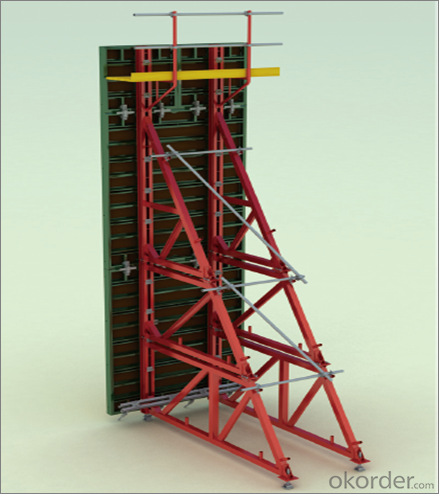

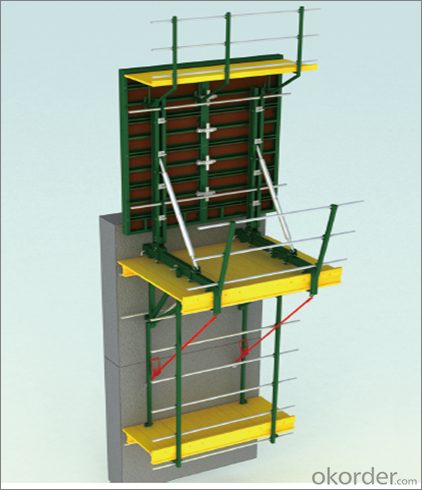

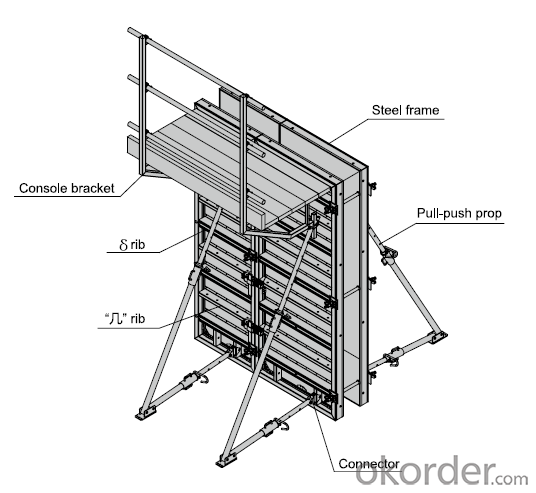

1. Structure of Steel Frame Formwork

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

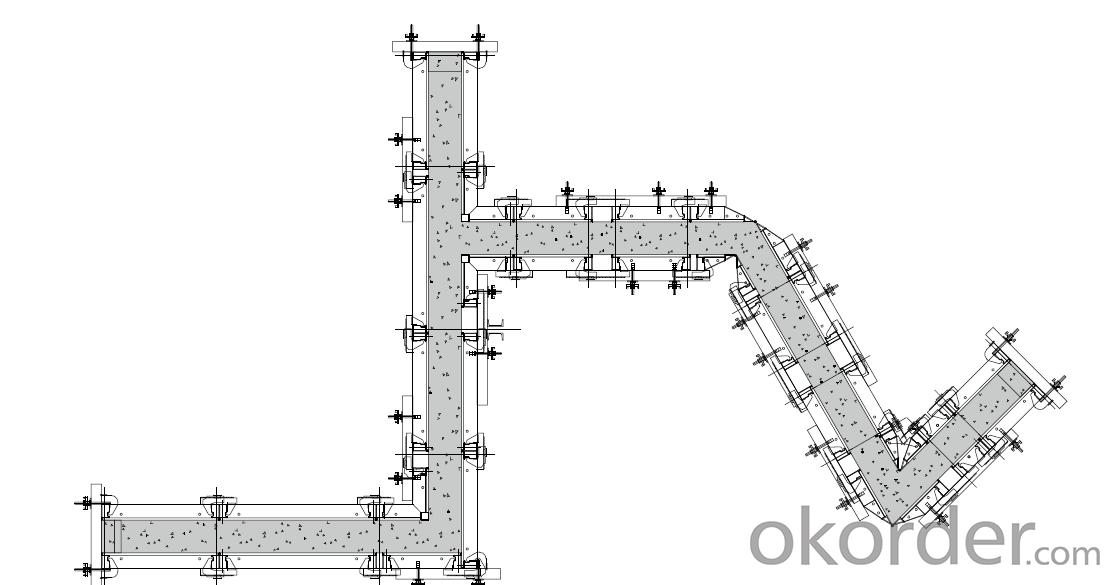

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

3. Steel Frame Formwork Images

4. Steel Frame Formwork Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

5. FAQ of Steel Frame Formwork

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel Frame Formwork , please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel Frame Formwork , we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Can steel frame formwork be used for the construction of recreational facilities?

- Recreational facilities can indeed utilize steel frame formwork for their construction needs. This versatile and durable solution is capable of withstanding the heavy loads and demands that come with recreational facilities. By providing a strong structural support system, steel frame formwork can easily be customized to meet the specific design requirements of sports stadiums, indoor arenas, swimming pools, and amusement parks. The use of steel frame formwork offers numerous advantages in the construction of recreational facilities. One of the main benefits is its high level of flexibility and adaptability. Steel frames can be easily modified and adjusted to accommodate different shapes and sizes of recreational facilities, optimizing space utilization and ensuring optimal functionality. This makes it suitable for constructing anything from a small community center to a large-scale sports complex. Furthermore, steel frame formwork boasts excellent strength and durability, ensuring the structural integrity of the recreational facility. Steel is renowned for its exceptional load-bearing capacity, allowing it to support heavy equipment, seating arrangements, and other necessary infrastructure for recreational activities. Additionally, steel can withstand extreme weather conditions and natural disasters, guaranteeing a safe and secure environment for facility users. Moreover, utilizing steel frame formwork allows for a faster construction process compared to traditional methods. The prefabricated nature of steel frames enables quick and efficient assembly, reducing both construction time and costs. This is particularly advantageous for recreational facilities where time is of the essence, such as in preparation for a sporting event or the opening of a seasonal amusement park. In conclusion, steel frame formwork is a viable option for the construction of recreational facilities. Its flexibility, strength, and efficiency make it an ideal choice for creating safe and functional spaces for various recreational activities.

- Q: What are the different types of accessories and attachments available for steel frame formwork?

- There are several different types of accessories and attachments available for steel frame formwork. These accessories and attachments are designed to enhance the functionality and efficiency of the formwork system and make the construction process smoother. One of the most common accessories is the adjustable prop. Adjustable props are used to support the formwork system and ensure its stability. These props can be easily adjusted to different heights, allowing for flexibility in construction projects. Another important accessory is the formwork clamp. Formwork clamps are used to securely fasten the formwork panels together, preventing any movement or displacement during the concrete pouring process. Formwork brackets are also commonly used accessories. These brackets are attached to the steel frame formwork and help to support the formwork panels and beams. They provide additional stability and strength to the system. Other accessories include formwork connectors, which are used to connect the formwork panels together, and formwork ties, which are used to secure the formwork system to the structure being constructed. In addition to these accessories, there are also various attachments available for steel frame formwork. One example is the formwork corner, which is used to create sharp corners and angles in the formwork system. This attachment ensures that the formwork system can be adjusted to fit the specific design requirements of a construction project. Another attachment is the formwork bracket arm. This arm is used to extend the reach of the formwork brackets, allowing for greater flexibility in formwork placement. Overall, the different types of accessories and attachments available for steel frame formwork are designed to enhance the stability, flexibility, and functionality of the system. These accessories and attachments help to create a more efficient and effective construction process, resulting in a higher quality finished product.

- Q: What are the common quality assurance procedures for steel frame formwork systems?

- Common quality assurance procedures for steel frame formwork systems include: 1. Material Inspection: This involves checking the quality and specifications of the steel used in the formwork system, ensuring it meets the required standards and is free from any defects. 2. Welding Inspection: As steel frame formwork systems are typically welded together, it is essential to inspect the welding quality. This includes checking for proper weld penetration, absence of cracks or porosity, and ensuring that the welds are strong and secure. 3. Dimensional Accuracy: The formwork system should be closely inspected to ensure that it meets the required dimensions and tolerances. This includes checking the alignment of the steel frames, the straightness of the members, and the accuracy of the formwork structure as a whole. 4. Load Testing: Load testing is performed to determine the structural integrity and load-bearing capacity of the formwork system. This involves subjecting the system to various loads and ensuring that it can withstand them without any deformation or failure. 5. Surface Coating Inspection: Steel frame formwork systems are often coated with protective paints or coatings to prevent corrosion and enhance durability. These coatings should be inspected to ensure proper coverage, adhesion, and protection against corrosion. 6. Documentation and Certification: Quality assurance procedures also involve proper documentation and certification of the formwork system. This includes keeping records of inspections, test results, and certifications from third-party testing agencies to demonstrate compliance with industry standards and regulations. 7. Continuous Monitoring: Quality assurance procedures also involve continuous monitoring and surveillance of the formwork system during its use. This includes regular inspections, maintenance, and repairs to ensure that the system remains in optimal condition and can perform its intended function safely and efficiently. By implementing these quality assurance procedures, steel frame formwork systems can be ensured to meet the required standards, providing a reliable and durable solution for construction projects.

- Q: How does steel frame formwork affect the overall quality of the concrete structure?

- The utilization of steel frame formwork is essential for maintaining the overall quality of a concrete structure. This specific formwork system serves as a robust and inflexible framework that provides support for the wet concrete throughout the pouring and curing stages. Its design is intended to withstand the pressure exerted by the concrete, ensuring that it retains its shape and integrity until it solidifies. An important advantage of using steel frame formwork is its capacity to produce smooth and precise concrete surfaces. The steel panels are manufactured with high precision, ensuring that they fit together seamlessly to create a uniform surface. This results in a finished concrete structure that is devoid of defects such as unevenness, honeycombing, or formwork marks. Furthermore, the smooth surface enhances the aesthetic appeal of the structure. Furthermore, steel frame formwork offers exceptional dimensional accuracy to the concrete structure. The rigid steel framework guarantees that the dimensions of the formwork remain consistent and do not change during the pouring process. This helps eliminate any variations or distortions that may occur due to the weight or pressure of the wet concrete. Consequently, the final structure is constructed according to exact specifications, ensuring precision and reliability. Another benefit of utilizing steel frame formwork is its durability and reusability. Steel is a sturdy material that can withstand the harsh conditions of construction sites, such as heavy loads, vibrations, and exposure to weather elements. This durability allows the formwork to be utilized multiple times, reducing construction costs and minimizing waste. Additionally, the ability to reuse the formwork maintains consistency and quality across multiple projects. Moreover, steel frame formwork provides excellent structural stability and strength to the concrete structure. The steel panels and supports are designed to withstand the pressure exerted by the wet concrete, ensuring that the formwork remains stable and secure. This stability is crucial in preventing any deformation or collapse during the pouring and curing process, which could compromise the overall quality and safety of the structure. In conclusion, the utilization of steel frame formwork significantly influences the overall quality of a concrete structure. It ensures smooth and precise surfaces, dimensional accuracy, durability, and structural stability. By providing a strong and inflexible framework, steel formwork contributes to the creation of high-quality, aesthetically pleasing, and dependable concrete structures.

- Q: How does steel frame formwork handle the construction of suspended slabs and beams?

- A versatile and efficient method for constructing suspended slabs and beams is the use of steel frame formwork. This construction technique involves the utilization of a specially designed steel frame to support and secure the concrete during the pouring and curing process. The strength and durability of steel frame formwork are key advantages, making it an ideal choice for bearing the weight of suspended slabs and beams. The steel frame can withstand the pressure and weight of the concrete, ensuring stability and security throughout the construction process. Additionally, steel frame formwork offers flexibility in design and customization. It can be easily adjusted and modified to meet the specific requirements of different slab and beam configurations. This grants contractors the ability to create intricate and unique designs without compromising structural integrity. Furthermore, steel frame formwork provides a smooth and uniform surface finish, resulting in high-quality and visually appealing slabs and beams. The formwork system is designed to prevent any leakage or seepage of the concrete, guaranteeing a durable and aesthetically pleasing structure. Moreover, steel frame formwork allows for faster construction times compared to traditional methods. The prefabricated steel frames can be effortlessly assembled and disassembled, enabling efficient installation and removal. This reduces overall construction time and increases productivity on the construction site. In conclusion, the utilization of steel frame formwork for suspended slabs and beams offers numerous benefits, including strength, durability, flexibility, and efficiency. It is a reliable and cost-effective construction technique widely used in the industry.

- Q: What are the different types of concrete finishes that can be achieved with steel frame formwork?

- Steel frame formwork allows for the attainment of various concrete finishes. 1. The smooth finish is the most commonly achieved type. It involves ensuring the formwork is level and free of debris or imperfections, resulting in a smooth and even surface suitable for most applications. 2. The exposed aggregate finish is achieved by removing the top layer of concrete to reveal the aggregate beneath, such as stones or pebbles. This can be facilitated by incorporating removable top panels or utilizing specialized formwork systems. 3. The stamped finish involves using formwork with patterns or textures on its surface. By pressing the formwork into fresh concrete, a pattern or texture resembling stone, brick, or other materials is created. This finish enhances the aesthetic appeal of surfaces like driveways, walkways, and patios. 4. The polished finish is achieved by using formwork with a smooth and non-porous surface. After the concrete cures, it is polished using specialized equipment and diamond abrasive pads, resulting in a highly reflective and smooth surface commonly used in upscale residential and commercial applications. 5. The stained finish involves applying a chemical stain or dye to the concrete surface. Formwork can be designed to accommodate this finish by incorporating a release agent or utilizing specialized systems that facilitate easy application of the stain or dye. This finish adds color and visual interest to surfaces like floors, countertops, and walls. In conclusion, steel frame formwork offers versatility and flexibility in achieving different concrete finishes. By properly planning, preparing, and executing these finishes, the visual appeal and functionality of concrete structures can be enhanced.

- Q: Does steel frame formwork require any specialized equipment for installation?

- Yes, steel frame formwork typically requires specialized equipment for installation. This can include cranes or other heavy lifting machinery to position and secure the steel frames in place. Additionally, specialized tools may be necessary for aligning and connecting the formwork components accurately.

- Q: How does steel frame formwork differ from other types of formwork?

- There are several notable distinctions between steel frame formwork and other formwork varieties. To begin, steel frame formwork is composed entirely of steel, rendering it exceptionally robust and long-lasting. It can endure substantial loads without warping or bending, making it ideal for construction endeavors necessitating considerable strength and stability. Moreover, steel frame formwork boasts exceptional adaptability. It can be easily customized and adjusted to accommodate structures of various shapes and sizes. This flexibility permits the creation of intricate and distinctive designs that would be otherwise unattainable with alternative formwork options. Furthermore, steel frame formwork guarantees superior stability and precision. The steel frames offer excellent support, ensuring that the formwork remains securely in place throughout the concrete pouring and curing process. This results in superior construction quality and heightened accuracy. Additionally, steel frame formwork enjoys a lengthier lifespan compared to other formwork alternatives. Its durability and resistance to wear and tear enable its repeated use, rendering it an economically advantageous choice in the long term. Lastly, steel frame formwork can be assembled and disassembled relatively swiftly and effortlessly. The steel frames can be conveniently transported and put together on-site, saving time and labor expenses. This efficacy proves particularly beneficial for projects with tight time constraints or limited resources. In conclusion, steel frame formwork distinguishes itself from other formwork options due to its strength, versatility, stability, durability, and user-friendliness. These qualities make it an exceptional selection for construction ventures necessitating exemplary performance and efficiency.

- Q: Is steel frame formwork resistant to fire?

- Yes, steel frame formwork is resistant to fire. Steel is a non-combustible material that does not contribute to the spread or intensification of fires. It has a high melting point, typically around 1370 degrees Celsius, which means it can withstand high temperatures without losing its structural integrity. This makes steel frame formwork a safe and reliable choice for construction projects where fire resistance is a concern. Additionally, steel's durability and strength ensure that the formwork remains intact even in extreme fire conditions, providing added protection to the structure being built.

- Q: How does steel frame formwork ensure proper alignment of columns and beams?

- The rigid and accurate construction of steel frame formwork ensures the proper alignment of columns and beams. The steel frame is precisely designed and manufactured to create a strong and stable structure for the formwork system. To begin with, the steel frame formwork is specifically designed to perfectly fit around the columns and beams, ensuring a tight and secure fit. This prevents any movement or shifting while pouring and curing the concrete. The formwork is typically adjustable, allowing for easy alignment of the columns and beams to the desired position. This adjustability enables the formwork to accommodate different sizes and shapes of columns and beams. Furthermore, the steel frame formwork provides a level and even surface for pouring concrete. The formwork is usually equipped with adjustable metal props or jacks, allowing for precise adjustment of the height and level of the columns and beams. This ensures that the concrete is poured onto a level surface, preventing any unevenness or sloping in the final structure. In addition, the steel frame formwork is designed to withstand the pressure and weight of the concrete during the pouring process. The steel frame is constructed with strong and durable materials, guaranteeing that it can support the weight of the concrete without any deformation or movement. This stability and rigidity of the formwork prevent any misalignment or distortion of the columns and beams. In summary, the steel frame formwork system guarantees the proper alignment of columns and beams by providing a rigid, adjustable, and level structure for pouring concrete. It ensures accurate positioning of the columns and beams, resulting in a structurally sound and aesthetically pleasing final construction.

Send your message to us

Steel Frame Formwork for Constrction with High standardized System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords