Stainless Steel Centrifugal Pump Electric High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Company Introduction

My company has more than 40 years history, is the China general machinery pump industry association member units.

The company has organized product research and development team, experienced high, intermediate technical staff.Complete production and processing, inspection, testing (pump performance test platform), and other equipment, to ensure that product quality is stable and reliable.Over the department, provincial, municipal and industry product quality supervision and inspection (smoke), only one is qualified to go through.Timely quality perfect after-sales service in place, favored by the majority of new and old customers rely on and praise.

The company has successfully passed the national industrial products production license, ISO9001 quality system review replacement work.Relevant product standards (enterprise), metrology, standardization management system, etc., have been acceptance by the superior department in charge of the inspection.Related to product development, production management, sales and after-sales service, are performed according to the system management standard.

Manufacturing process:

1.Stamping of lamination

2.Rotor die-casting

3.Winding and inserting – both manual and semi-automatically

4.Vacuum varnishing

5.Machining shaft, housing, end shields, etc…

6.Rotor balancing

7.Painting – both wet paint and powder coating

8.Motor assembly

9.Packing

10.Inspecting spare parts every processing

11.100% test after each process and final test before packing

Features

1. Hydraulic design with wide flow-path non-clogged structure ,allowed fibres(3 times

length of inlet diameter),particles(30% size of inlet diameter )

2. Excellent design,high efficiency and energy saving .

3. Double mechnical seals in series,made of hard alloy corrosive proof silicon

carbide,which is durable and .wearable ,that enable pump safely operation for more

than 8000 hours continous.

4. Compact structure, small volume, easy moved and conveniently mounted , no need build

pump house, greatly reduct the cost.

pump superiority

High efficiency

Reasonable design

Reliable operation

Long in service time

Easy maintenance

Low running cost

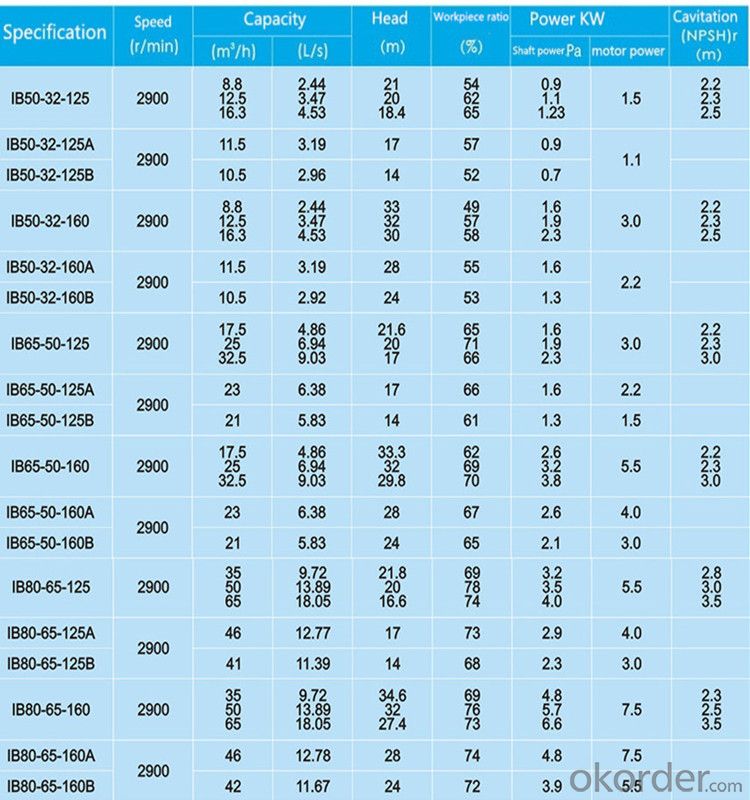

Product specification

Pictures show

Transportation

- Q: removed my water pump to replace it. i have the fan and clutch assembly still attached...i have no idea how to remove these...the fan clutch has bolts that hold the fan to it...and i did remove those but im just not sure how to separate this assembly...my water pump pulley has 4 holes...and no bolts so i presume it's pressed on...and there looks to be a very large nut between the pulley and the fan/clutch assembly...any help would be appreciated on this...i'd much rather go to the parts store w/ the old pump instead of guessing.....thnx in advance...

- The fan has a large nut that needs to unscrew off of the water pump. It is easiest to do that when pump is still on engine. It should be standard righthand thread.

- Q: I took out the thermostat, filled coolant level to upmost, my car still overheats, it doesnt leak ne where.How can I tell if the water pump is workin?

- if you can look down inside the radiator watch the water see how it moves.... check you hoses if any of them are soft or fat looking.... and it dont have to leak to be bad but in most cases it leaks..... most of the time when a car over heats its a flow thing

- Q: Water pump part is stainless steel, which part is it?

- Of any part of the body that is in contact with water

- Q: How much would a water pump cost for a 1991 cadillac deville

- A lot!!

- Q: The meter on my dash was reading low even after driving for 20 minutes on a sunny day. Then all of a sudden it jumped over the 270 mark. I have a relatively new thermostat could my water pump have gone bad? I did not see any leaking coolant or anything under the vehicle.

- first check the coolant level, make sure it is full, this may be all it is, it could also be the thermostat went bad, this is not that unusual for a new thermo. to fail, make sure the belt to the pump is good, unlikely the pump is bad if it is not leaking or making any noise at all! but, when the new thermo. was installed did you purge all the air from the system, at times and in some autos air will become trapped and you have to bleed the air out of it, some have a bleeder screw and some don't, the ones that do not have a bleeder then you have to raise the front end of the car to the point where the radiator top is higher than the engine and make sure the heat is turned on and set to high!

- Q: how much would they charge me to change a water pump on my 1999 cadillac deville

- 2 or 3 hours of labor depends on the shops labor rate if it is a northstar it is on the drivers front of the engine by the rad hose (inside the crossoverpipe) or if it is the older engine it is on the pass side side by the drive belt (thin and long)

- Q: Where is the water pump located in a 1995 Toyota tacoma pick up truck. Please be as specific as possible as the the location of the pump. Like what is it undwr or next to...etc

- on the front of the engine..running off one of the belts

- Q: Why can't vertical water pump use spring shock absorber?

- Vertical pump power is small, the weight is limited, the pipeline vibration is limited, the general rubber shock absorber will be enough. It's no use. I'm sure you can't use the spring shock absorber.General construction, 7,5KW below is rubber shock absorber, above is spring shock absorber

- Q: Why is the water pump usually used multi-stage pumps, while the circulating pump is usually a single-stage pump?

- Mainly determined by the function of the water supply pump and the circulation pump.Replenishment pump is mainly to supplement the loss of the system, so the general flow is smaller, larger head, single pump water model in a small flow situation, many are not up to the required head, can only use multi-stage pumps.Circulating pumps are generally large flow, low lift, heavy efficiency, economic operation, and hydraulic model point of view, are single-stage pumps more appropriate, especially single stage double suction pump.

- Q: hooking up a water pump to my tank and need a power supply

- can you be a bit more descriptive have you a pump but no way of powering it if so what type of pump what voltage where is pump

Send your message to us

Stainless Steel Centrifugal Pump Electric High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords