Stainless Steel Centrifugal Pump High Pressure

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

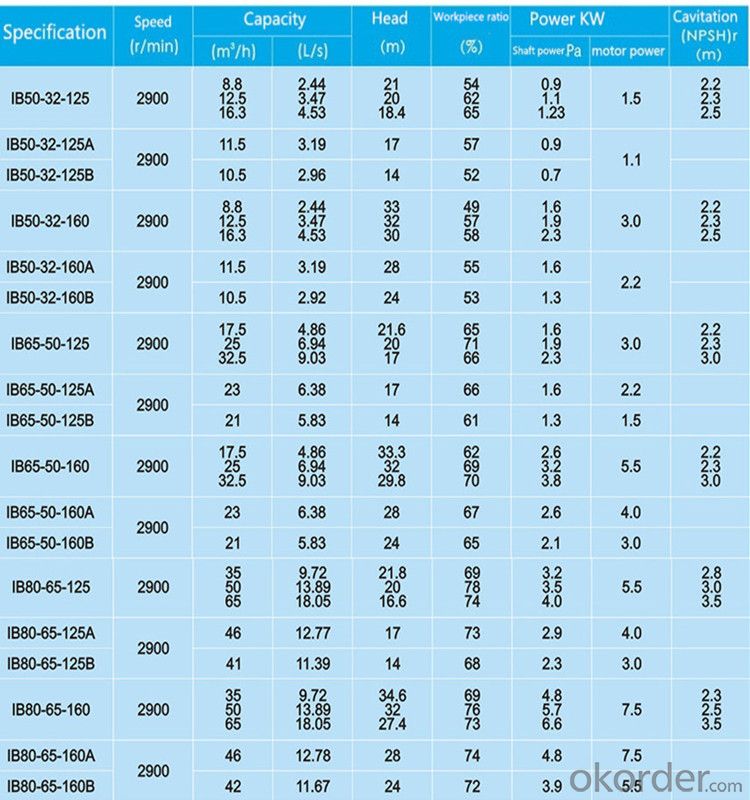

Specification

Company Introduction

My company has more than 40 years history, is the China general machinery pump industry association member units.

The company has organized product research and development team, experienced high, intermediate technical staff.Complete production and processing, inspection, testing (pump performance test platform), and other equipment, to ensure that product quality is stable and reliable.Over the department, provincial, municipal and industry product quality supervision and inspection (smoke), only one is qualified to go through.Timely quality perfect after-sales service in place, favored by the majority of new and old customers rely on and praise.

The company has successfully passed the national industrial products production license, ISO9001 quality system review replacement work.Relevant product standards (enterprise), metrology, standardization management system, etc., have been acceptance by the superior department in charge of the inspection.Related to product development, production management, sales and after-sales service, are performed according to the system management standard.

Product specification

Application

Mainly apply to delivery sewage water ,waster water and rain water contains solids and

fibres:

*municipal project

*building construction

*residential area

*industrial sewage treatment

*eviroment protect

*mining

Features

1. Hydraulic design with wide flow-path non-clogged structure ,allowed fibres(3 times

length of inlet diameter),particles(30% size of inlet diameter )

2. Excellent design,high efficiency and energy saving .

3. Double mechnical seals in series,made of hard alloy corrosive proof silicon

carbide,which is durable and .wearable ,that enable pump safely operation for more

than 8000 hours continous.

4. Compact structure, small volume, easy moved and conveniently mounted , no need build

pump house, greatly reduct the cost.

pump superiority

High efficiency

Reasonable design

Reliable operation

Long in service time

Easy maintenance

Low running cost

Pictures show

Transportation

FAQ

1.Q: What is your payment term?

A: 30% T/T in advance, 70% when receiving B/L copy. Or irrevocable L/C.

2.Q: What is your lead time?

A: Within 20-25 days after receiving deposit or original L/C.

3.Q: Do you offer OEM service?

A: Yes. We manufacturer can custom designed for any specific application.

- Q: We bought a plot of land and me and my father found a deactivated water well in there. We checked and it's 328 feet deep and is still full of water.How would i go about setting up a pump on it?

- Water pump setup? We bought a plot of land and me and my father found a deactivated water well in there. We checked and it's 328 feet deep and is still full of water. How would i go about setting up a pump on it? Best thing to do is call a plumber and ask about hooking up a well to a house. You can use a submersible pump or have the pump located somewhere near the well head or in a building nearby (a pump house say). Because it is so involved and back-breaking work, it is better to hire a PRO.

- Q: What I am trying to explain is that I took my vehicle to be serviced for a water pump. They installed it, but when I got my vehicle back, it started making this clicking noise. I took it back to be diagnosed and they came back to me saying that I need a new engine? (Before I took in my vehicle there was no clicking sound or problems, just the water pump.)Could this be the dealer trying to pull something for their mistake or what?

- What kind of vehicle?' Depending on the car they may of had to remove the timing belt to access water pump and possibly not set timing correct or left a tensioner loose or soemthing. Did they tell you why you need a new engine?

- Q: i have a 1960 ford f100 and i was wondering if its better to have an electric water pump or mechanical. ive heard mechanical is worse because at low rpms it doesnt put as much water into the motor but i wasnt sure how true that was. What was is better so that my truck doesnt overheat? and how much better is one over the other if electric will just be a little better is it even worth using? also will i need to change anything on my motor to be able to put an electric water pump on it or will it just bolt on like the mechanical one does

- Well your mechanical water pump is more than sufficient to pump water through your engine even at low rpms. Whether you have a electric or mechanical your can't pump more water though your engine than what your thermostat will allow you to. The advantage that i can see over electric would be the extra horse power you might get over having your mechanical

- Q: What is the defection of water pump

- Anti water hammer phenomenon that is usually said, it is in the high pressure water pump suddenly stops working, the height would hit back phenomenon called defectionThis situation generally occurs in the water pump outlet does not install a check valve, the valve with a check valve has a sound, but the check valve can be a good protection of water pump

- Q: I am having overheating issues with my 1993 3.4L V6 Camaro,Once I start the car with no AC or Heat on while at idle or driving the car will overheat, almost to the red line. When I get onto the highway it will slowly drop all the way down to operating tempeture.Also if I turn on either the AC or Heat while driving around town the car will not overheat.On my way home I turned everything off and let the car overheating, when I got home I opened the hood and the fans are going but still overheating.Also the major sympton is that the water pump will click on and off when I have AC blowing. It will click on and off every 10 seconds or so.New waterpump?

- I should change the water pump. The vains or fins in the housing are probably worn. You will see that they are when you pull off and flip it over. Those fins is what keeps the water moving......Steve

- Q: how to replace water pump 97 pontiac bonneville?

- It depends on which engine you have, with or without a supercharger. The non-supercharged engine is a piece of cake. the supercharged one is a bit of a pain to get at the water pump. On the non-supercharged engine, all you need to do is remove the serpentine belt, the water pump pulley and the bolts that hold the water pump to the front cover. I have detailed instructions if you send me your email address I can give them to you. They are from GM Service Information website. I can't give you the link to the website because I have to enter a password to enter the site through work.

- Q: When I buy submersible pump, the other party did not inform is the aluminum submersible pump, water pump factory production of aluminum submersible pump illegal? Is it against the law to sell the pump to the pump without informing me?

- No, the state does not have special laws to prohibit the use of aluminium wireIn fact, the aluminum core wire or mechanical or good, low prices, especially in the dry environment of small and medium-sized mechanical and electrical, with good performance. Only in the submersible pump, because aluminum is easier than copper wire, moisture infiltration, bacteria and other corruption, and its survival time is sometimes less than copper wire. But the pump inlet, aluminum often requires rewinding coil, because of a small submersible pump well around Electromechanical General scrap. Therefore, the quality of submersible pumps will not generally use aluminum, but the production of aluminum submersible pump is not illegal, but in the sale should be based on the principle of honest business detailed notification.

- Q: How do I change the water pump in my 1998 ford mustang manual v6?

- If you don't already know how to do it, then take it to a shop to have it done by the professionals. If you insist on trying it yourself, buy a Chilton's manual for your car, do some online research (with pictures), and buckle down. You will need to loosen the belts, remove the belts, remove the water pump, replace it, and reinstall everything. You will need to make sure that the belt is routed the correct way, or BOOM! You might also want to replace the timing belt while you're in there. It makes sense to replace it if you already are removing it, and the timing belt is something you can't afford to have go bad on you.

- Q: leaking coolant after the car engine has stoppped

- Some water pumps have weeping holes, if water is coming out of those then it is definitely your problem.

- Q: Sewage treatment plant design how many pumps should be selected, head how to calculate the maximum design flow is 833M3/h

- Is the sewage treatment bar, you have to choose corrosion-resistant pump, sewage treatment lift is generally not high, and then you flow so much, the choice of axial flow pump is the best choice, specific models only you go online to check. The information I provide is the choice of corrosion resistant axial pumps. Then, if there is impurities, it is best to use the axial flow pump with mixing function.

Send your message to us

Stainless Steel Centrifugal Pump High Pressure

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords