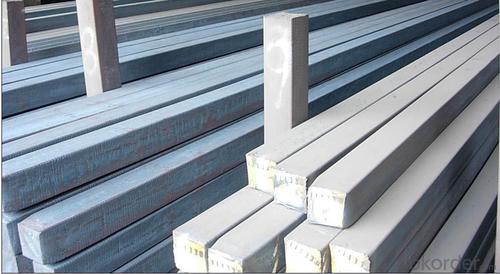

Square Steel Billet Q235 Grade Prime Quality 6#

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Square Steel Billet Q235 Grade Prime Quality 6#

M. S. Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products.

CRS Billets are used for rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like Earthquake resistant TMT Re-Bars and for special grade structural steel products.

Main Feature Square Steel Billet Q235 Grade Prime Quality 6#

Raw elements(C,Fe,Ni,Mn,Cr,Cu.)---Smelted ingots by AOD finery---hot rolled into black suface---pickling in acid liquid---cold drawn----polished by automatically machine--- cutting into pieces---checking quanlity

Applications of Square Steel Billet Q235 Grade Prime Quality 6#

Widely Used in the areas such as Stainless Steel Fasteners, Chains, Kitchen and Sanitary wares, Furniture handles, Handrails, Electroplating and Electrolyzing pendants, Foods, Electron, Petroleum, Construction and Decoration, etc. Products have a high strength after cold-working. Electronic products parts, Medical appliance, Springs, Bus Inside and Outside packaging and building, Street Lamp Posts, etc. Decoration materials and Outdoor Publicity Billboard. Used for the products which have the Anti-Stress Corrosion requirement. Electron Products, Table-wares, Bolts, Nuts, Screen Meshes, Cumbustors and so on.

Specifications of Square Steel Billet Q235 Grade Prime Quality 6#

| Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

| Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

| Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

| Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

| 20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

| 3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

| 5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

FAQ of Square Steel Billet Q235 Grade Prime Quality 6#

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How are steel billets different from steel ingots?

- Steel billets and steel ingots are both intermediate products in the steel manufacturing process, but they differ in terms of their shape and size. Steel billets are smaller and have a square or rectangular cross-section, typically measuring less than 36 square inches. In contrast, steel ingots are larger and have a more irregular shape, often weighing several tons. Additionally, steel billets are typically produced using continuous casting methods, while steel ingots are typically made through traditional ingot casting processes.

- Q: How do steel billets contribute to the infrastructure development?

- Steel billets are a crucial component in infrastructure development as they serve as the raw material for manufacturing various steel products used in construction. These billets are used to produce reinforcement bars, beams, columns, and other structural elements that provide strength and stability to buildings, bridges, roads, and other infrastructure projects. By providing a strong and durable foundation, steel billets contribute significantly to the overall safety and longevity of infrastructure, promoting sustainable development and economic growth.

- Q: How are steel billets used in the manufacturing of agricultural machinery parts?

- Steel billets serve as a crucial raw material for the production of agricultural machinery parts. These billets are essentially semi-finished steel products that act as a starting point for various manufacturing processes. To begin with, steel billets are molded into specific shapes using a range of techniques such as casting, rolling, or extrusion. These processes facilitate the transformation of solid billets into desired forms like bars, rods, or sheets, which then serve as the foundational materials for agricultural machinery parts. After the billets have been shaped, they undergo further refinement through machining, cutting, and welding procedures to create precise components for agricultural machinery. For instance, billets can be machined into shafts, gears, or axles that are integral to the functioning of these machinery parts. Furthermore, the robustness and durability of steel billets make them well-suited for use in heavy machinery like tractors, combines, or harvesters. Agricultural machinery parts manufactured from steel billets possess exceptional tensile strength, resistance to wear and tear, and the ability to withstand the demanding conditions encountered in the agricultural sector. Moreover, steel billets can be subjected to heat treatment to enhance their mechanical properties, such as hardness or toughness, thereby making them more resilient and capable of enduring substantial loads and extreme conditions. This makes them an ideal choice for agricultural machinery parts that frequently encounter intense forces during operation. Additionally, steel billets can be utilized in the production of precision components, such as bearings or bushings, which are vital for the smooth and efficient operation of agricultural machinery. The dimensional accuracy and consistency of steel billets ensure that these precision parts fit flawlessly and perform effectively. Overall, steel billets play a pivotal role in the manufacture of agricultural machinery parts. Their versatility, strength, and ability to be shaped and processed make them an indispensable material in the production of components that can withstand the demanding and challenging conditions prevalent in the agricultural industry.

- Q: How are steel billets used in the manufacturing of construction materials?

- The manufacturing of construction materials relies heavily on steel billets, which are a necessary raw material. These semi-finished forms of steel serve as the initial stage for various construction products, including rebars, beams, columns, and plates. During the production process, steel billets undergo heating and are then passed through a series of rolling mills to achieve the desired shape. For example, when producing rebars, the billet is heated and rolled into long, slim bars of different diameters. These rebars are commonly used in construction to reinforce concrete structures, ensuring their durability and strength. Likewise, steel billets are utilized in the creation of beams, columns, and plates, which are essential elements in building construction. Beams provide structural support, while columns bear the weight of the structure and transmit loads to the foundation. Plates, on the other hand, find applications in flooring, walls, and roofing. The utilization of steel billets in construction materials offers numerous benefits. Steel, renowned for its high strength-to-weight ratio, provides exceptional structural integrity, resulting in more efficient and cost-effective construction. Furthermore, steel is highly ductile, allowing it to be easily shaped and molded into various forms, enabling versatility in design and construction. Additionally, steel is a durable material that exhibits excellent resistance to environmental factors like corrosion and fire. Consequently, steel construction materials have a long lifespan and are suitable for a wide range of applications, including high-rise buildings, bridges, and infrastructure projects. In conclusion, steel billets play a vital role in the manufacturing of construction materials. By being transformed into rebars, beams, columns, and plates, these billets provide the necessary strength, durability, and versatility required in the construction industry.

- Q: What is the role of steel billets in the production of sheet metal?

- The production of sheet metal heavily relies on steel billets, which serve as the primary raw material. These billets are essentially solid bars of steel, typically rectangular or square in shape, and are produced through casting or hot rolling. Depending on the specific requirements of the sheet metal being manufactured, steel billets are produced in various sizes and lengths. To begin the production process, the steel billets are heated to a high temperature and then passed through a series of rolling mills. This rolling process is aimed at reducing the thickness of the billets and increasing their length. By applying pressure to the billets, they elongate and become thinner. This continuous rolling process is repeated multiple times until the desired thickness is achieved. Once the steel billets have been transformed into thin sheets, further processing is carried out to obtain the final sheet metal product. This may involve additional steps such as cutting, trimming, and surface treatments to enhance both the appearance and properties of the sheet metal. Steel billets are highly favored in the production of sheet metal due to their exceptional mechanical properties. Steel is renowned for its strength, durability, and malleability, making it an ideal material for sheet metal applications. By utilizing steel billets, the resulting sheet metal products possess these desirable properties. To summarize, steel billets serve as the starting point in the production of sheet metal. Through heating and rolling processes, the billets are transformed into thin sheets of steel, which are then further processed to create the final sheet metal products. The use of steel billets is crucial in ensuring the production of sheet metal with superior mechanical properties, making it an indispensable component in the manufacturing industry.

- Q: How are steel billets used in the manufacturing of aerospace components?

- Steel billets are used in the manufacturing of aerospace components as they provide a crucial starting material for the production of various parts. These billets, which are essentially semi-finished steel products in the shape of a square or rectangular solid, undergo a series of processes to transform them into the required aerospace components. Firstly, steel billets are subjected to a heating process known as "hot working." This involves heating the billets to high temperatures, typically around 1200-1300°C, to make them more malleable and easier to shape. The heated billets are then passed through a series of rolling mills, where they are gradually reduced in size and shaped into the desired forms, such as bars, rods, or sheets. Once the steel billets are transformed into the desired shapes, they are further processed through various techniques like forging, extrusion, or machining to create specific aerospace components. For example, the billets can be forged or machined to produce critical parts like engine shafts, landing gear components, or structural supports. The use of steel billets in aerospace manufacturing offers several advantages. Steel is known for its high strength, durability, and excellent mechanical properties, making it an ideal material for aerospace applications. Steel components can withstand extreme conditions, such as high temperatures and pressures, as well as resist corrosion and fatigue, ensuring the safety and reliability of aerospace systems. Moreover, steel billets can be customized to meet the stringent requirements of aerospace components. By carefully controlling the composition, heat treatment, and manufacturing processes, steel billets can be tailored to provide specific properties, such as high strength-to-weight ratio, excellent heat resistance, or improved fatigue life. This customization ensures that the resulting aerospace components meet the demanding standards of the industry. In conclusion, steel billets play a vital role in the manufacturing of aerospace components. Through a series of heating, shaping, and processing techniques, steel billets are transformed into various forms that are then further processed to create critical aerospace parts. The use of steel as a material offers exceptional strength, durability, and customization possibilities, ensuring the production of high-quality and reliable aerospace components.

- Q: What are the advantages of using steel billets in the manufacturing process?

- There are several advantages of using steel billets in the manufacturing process. Firstly, steel billets have a consistent composition and uniformity, which ensures better quality control during production. Secondly, steel billets can be easily molded into various shapes and sizes, allowing for flexibility in design and manufacturing. Additionally, steel billets possess high strength and durability, making them suitable for applications that require robust materials. Moreover, steel billets can be recycled and reused, making them an environmentally friendly choice. Overall, the use of steel billets enhances the efficiency, reliability, and sustainability of the manufacturing process.

- Q: What is the average lifespan of a steel billet in a structural application?

- The average lifespan of a steel billet in a structural application can vary greatly depending on several factors. These factors include the quality of the steel used, the specific structural application, the environmental conditions, and the level of maintenance and care provided to the structure. In general, steel is known for its durability and longevity, making it a popular choice for structural applications. With proper design, construction, and maintenance, a steel billet can have a lifespan that ranges from several decades to over a century. However, it is important to note that certain factors can significantly impact the lifespan of a steel billet. For example, exposure to harsh environmental conditions such as extreme temperatures, corrosive substances, or high levels of humidity can accelerate the deterioration of the steel and reduce its lifespan. Similarly, the structural application itself plays a crucial role in determining the lifespan of a steel billet. Structures subject to heavy loads, frequent vibrations, or dynamic stresses may experience faster deterioration and require more frequent maintenance or replacement. Lastly, the quality of the steel used also influences the lifespan of a steel billet. Higher quality steels, such as those with superior corrosion resistance or higher tensile strength, tend to have longer lifespans compared to lower grade steels. To accurately determine the average lifespan of a steel billet in a specific structural application, it is recommended to consult with structural engineers, manufacturers, or industry experts who can evaluate the specific conditions and provide a more accurate estimate based on their expertise and knowledge of the particular project.

- Q: Does anyone know how much it costs to refine a ton of steel? What are the expenses involved?

- Electricity, water, wages, raw materials, raw materials loss, charges, oxygen, according to their own circumstances, as well as freight and other expenses,

- Q: How are steel billets used in the manufacturing of machinery and equipment?

- Steel billets are used in the manufacturing of machinery and equipment as they serve as the primary raw material for creating various components such as gears, shafts, and structural frames. These billets are heated and subjected to a series of shaping processes, such as rolling, forging, and machining, to form the desired shape and size of the machinery parts. The strength, durability, and versatility of steel make it an ideal choice for producing robust and reliable machinery and equipment.

Send your message to us

Square Steel Billet Q235 Grade Prime Quality 6#

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords